Knife Sharpener Double Sides Diamond Coated Stainless Steel Whetstone

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 50000 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Knife Sharpener Double Sides Diamond Coated Stainless Steel Whetstone

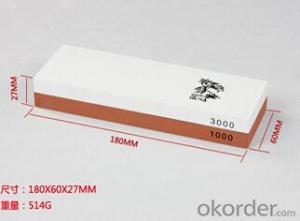

Stone Material:Diamond Coated Stainless Steel

Holder Material:plastic/stainless steel

Stone Size : 200*70*8mm

Weight: 1050g

Model no:LX-1012

Usage:Woodworking tools sharpening

OEM:YES

Package:color box

Diamond Whetstone Description:

Diamond coated stainless steel whetstone a durable, with a high hardness, excellent self-sharpening, grinding power, high efficiency, is an acid corrosion, high temperature and other characteristics on both sides of the duplex Whetstone different granularity from the will of each particle size Whetstone different grinding effect, so a Whetstone has two grinding performance, affordable and versatile.

Diamond Whetstone Scope:

Widely used in kitchen knives and garden tools, woodworking tools.

Diamond Whetstone Features:

1. Excellent sharpening performance

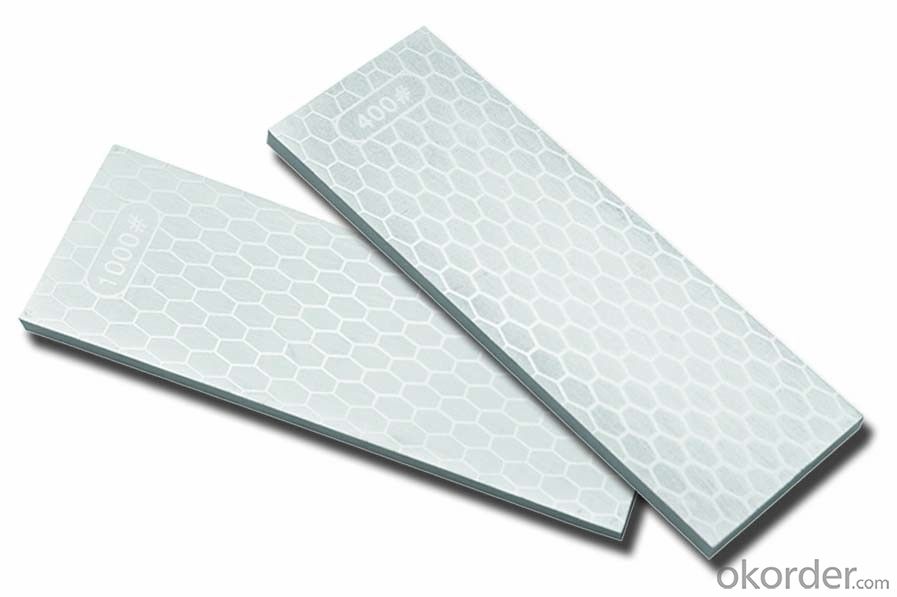

2. Double sided diamond design as 400Grit for coarse sharpen & 1000Grit for fine honing

3. Clear plastic cover protects the stone, molded plastic base with non-slip feet for safety

4. Oval hole design to collect and hold metal chippings

5.The high quality plastic holder keep the stone steady when sharpening,also protect your hand.

Diamond Whetstone Show

Using Instruction

1. Place the stone on a non-slip worktop and make sure the surface is flat.

2. Complete one or both of the following steps depending on how blunt the blades is.

Step1. for coarse sharpening: Used to repair badly damaged blade, suitable for a blunter knife.

Start by using the coarse 400 grit of the stone, move the blade back and forth over the stone at an angle of 10 - 30 ° by using light pressure.

Generally sharpen the tools with coarse stage every six months or as required.

Step 2. for fine honing; always finish off with this step to remove any burrs that result from the re-edging and rough honing process.

Using the 1000 grit of the stone, move the blade back and forth over the stone at an angle of 10 - 30 ° by using gentle pressure.

It is recommended to do it approximately once a week.

3. Clean the knife with the water or wiper and dry it after use and clean the knife sharpener with banister brush.

Caution:

1. Do not use the knife sharpener to sharpen serrated blades.

2. It would be much better to use with sharpening oil or water

4. Please don’t put sharpener in dishwasher or water

5. Please put the knife sharpener and knife beyond the reach of children to avoid any accidents.

- Q: Sharpening stone and sharpening rod which make

- You have to look at what to do with the edges of open front should use the grindstone three steps in the most thick about 200 mesh or a blade and then use about 500 of the burr and then polishing about one thousand meshes are generally not edged from ordinary knife before two step is enough if you are collecting or play knife appearance and extreme sharpness can add third step if the sharpness of the knife is hard to add a step with ruby grindstone (3000 mesh) and agate grindstone (8000 to 10000).If your knife is paused or just ordinary kitchen knife sharpener with rust. It can only be used for ordinary knife usually use tableware like playing with a knife sharpener, sharpener tube are called destroy knife can only be a few weeks with a knife grinding rust

- Q: Can a Zwilling knife be sharpened by another sharpener?

- Of course, the metal cutting tools are worn out, the difference is that the time of sharpening and the use of the knife itself material hardness.

- Q: What is a sharpener? What is the specific working principle? What are the advantages and disadvantages?

- The machine tool is a tool grinder, such as a high speed drilling machine for processing a printed circuit board, a numerical control machining center, a grinder with a drill bit and a cutter

- Q: Is it possible to use an ordinary whetstone? Will not damage the tool?

- Right, there is a special knife sharpener, or sharpened periodically better, if LZ do it yourself, ordinary grindstone, collocation Zwilling tool is not very good, may also damage the blade, anyway, my family is a special. If LZ does not want to spend money or too lazy to do it, you can go to the counter. Remember, oh, it's free and permanent!

- Q: Do you have a knife sharpener? Is there any good sharpener?

- Now there are many models such as Gangfeng sharpener, sharpener, knife fast three seconds

- Q: How do you use the sharpener? How to use

- There will be a knife slot knife on the knife slot on the push and pull a few

- Q: Is the kitchen knife a single blade? Can the sharpener be worn?

- The knife is a double edge, can use a sharpened knife sharpener

- Q: Enrich the knife sharpener?

- The sharpener is characterized by use of the traditional single knife to double knife, sharpening method, angle changed efficiency, cutting the most blunt no more than half a minute, and make it very sharp, its efficiency is really incomparable, the knife sharpener is material with special material processing refined, long service life, simple operation and cheap, it is an indispensable good helper housewife. Compared with the traditional knife sharpener, modern sharpener has the advantages of high speed, simple operation, easy to carry, beautiful appearance and so on. In addition, the knife does not need to add water and oil and other liquids. Very safe and sanitary to use. There are many kinds of types is the sharpener necessary sharpener modern kitchen supplies, a fixed angle, there are flat and rodlike; grinding material, high performance ceramics, diamond hard alloy and stone; the product is different, the price difference is large. So how to choose their own sharpener and satisfactory? We can discuss from several aspects, for reference for everyone to choose: first, knives or tools and material hardness: if your tool or tool steel for the better or higher hardness, diamond knife sharpener, high performance ceramic sharpener and stone three optional; if your tool and tool material is also hard alloy material than steel, the choice of high performance ceramic diamond knife sharpener, sharpener, especially recommended is diamond sharpener (such as grinding ceramic knife or hard alloy cutting tools, diamond sharpener is the only choice). Second, single edge tool or double...

- Q: Which kind of brand is good

- Locating the sharpener, can also be used with, and grinding after not easily scratch the hand, I hope to help you!

- Q: If there is no counter near the mill, you can grind it?

- Can be used sharpening stone, grinding time to use a little peanut oil or other oil can not use water! Force to light, knife and stone surface is about 45 degrees, a few light grinding on it. The sharpened edge is very smooth and sharp.

Send your message to us

Knife Sharpener Double Sides Diamond Coated Stainless Steel Whetstone

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 50000 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords