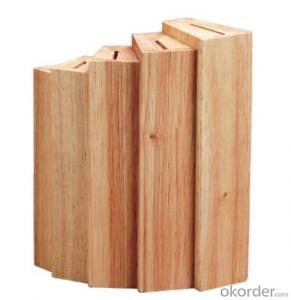

knife seat,F-KB026 Rubber wood knife seat,your best choice

- Loading Port:

- Guangzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

product name:rubber wood knife seat

material:rubber wood

MEAS:24*21*11cm

Specifications:

Has the quite distinct shape of the mountain wood grain, and the contact surface is a good sense

Excellent toughness, process into various curved according to the needs , full of beauty

Solid texture,manufactured goods with firm structure,prolonged service life

The texture of rubber wood is fine and closely woven,pore full of lots ot padding so it's hard to absorb water and corrode.

Primary Competitive Advantages:

Brand-name Parts Country of Origin

Distributorships Offered Experienced Staff

Form A Green Product

Guarantee/Warranty International Approvals

Packaging Price

Product Features Product Performance

Prompt Delivery

Main Export Markets:

Eastern Europe North America

Mid East/Africa Central/South America

Asia Western Europe

Australasia

- Q: The system is a wide number of 980TDb, lathe is the Yunnan machine tool factory. Whether it is a manual tool change or MDI way to enter the specified number of knives, the tool holder always turn around, until the emergence of PLC alarm 1000 change knife time is too long, A0000.0 knife can not reach the designated position. What the problem ah, I did not move the parameters of the machine, ah, this morning is good, work in the afternoon a boot on this.Back to the origin of the machine are abnormal, and can not return to the origin of the machine. Press the corresponding button after the machine does not respond, will not act. It's normal in the morning.

- I have encountered such a problem, the circuit has a capacitor breakdown, check the replacement can be.

- Q: How to save the supermarket roll bag?

- In the place of the roll bag placed in the food and goods, dry and wet varieties, such as the separation of each line of the front of the sale of things, do not half-way and tail placed, mainly with the sale of goods placed matching

- Q: Who has any good method or fixture drawings and pictures for younger brother to learn ah, do not be grateful, want to do, but I have not seen this thing, the idea does not come out

- Very simple, find a square on the grinder grinding angle four straight, like a knife, much bit big hole, the drill bit into a wire on the bit in the next attack on the line, but straight shank drill.

- Q: The difference between the center and the rest

- With the tool holder fixed on the side of the big carriage, with the longitudinal movement of the tool holder. There are two supporting claws with the tool holder, followed by the auxiliary supporting role behind the turning tool. Therefore, the tool post is mainly used for machining slender shaft. The use of the tool holder needs to first turn a circle on the right side of the workpiece, adjust the position and the tightness of the two supporting claws according to the outer circle, and then turn the full length of the optical axis.Use with the center frame and cutter, workpiece speed should not be too high, and the need to support with oil lubrication.

- Q: CNC turret can be turned into 45 degrees ah? Can you turn counterclockwise?

- 8 position of the numerical control turret, each turn 1 knife is 45 degrees, can be positive and negative (that is, clockwise and counterclockwise rotation)

- Q: These possibilities have been tested, or useless

- Loosen the guide rail and check the return circuit

- Q: What is the difference between numerical control tool holder and power tool holder

- Seems to be a thing. The knife of CNC machine tool CNC turret should refers to the (for the realization of automatic tool change in the process), can be divided knife straight row knife, disc knife, knife and other bamboo hat.

- Q: CNC lathe tool holder clamping bit how to clip

- If it is turret turret, machine tool manufacturers with drill sets, you can directly install straight shank drill, but the specification is not complete.

- Q: CNC lathe hit the knife after the knife center height, how to deal with?

- Turret positioning pin deformation! Contact factory maintenance

- Q: Fanuc CNC lathe tool holder for maintenance

- The turret to stop sending disc is bad, if you are a Shenyang machine tool equipment, suggest you directly contact the Shenyang machine tool factory sales office to buy the original knife from disk, too many fake goods on the market, the original letter disc type is JX-4 or JX-4W, JX-4B and JX-4BW on the market is full of fake goods, please discern

Send your message to us

knife seat,F-KB026 Rubber wood knife seat,your best choice

- Loading Port:

- Guangzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords