JIS & G/B Standard Steel Channel Module

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 2000 PCS

- Supply Capability:

- 40000 PCS/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

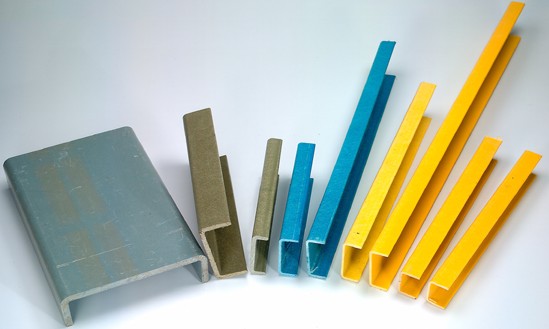

JIS & G/B Standard Steel Channel Module

OKorder is offering high quality JIS & G/B Standard Steel Channel Modules at great prices with worldwide shipping. Our supplier is a world-class manufacturer of steel, with our products utilized the world over. OKorder annually supplies products to European, North American and Asian markets. We provide quotations within 24 hours of receiving an inquiry and guarantee competitive prices.

Product Applications:

JIS & G/B Standard Steel Channel Modules are ideal for structural applications and general fabricating.

Product Advantages:

OKorder's Steel Channel Modules are durable, strong, and resists corrosion.

Main Product Features:

· Premium quality

· Prompt delivery & seaworthy packing (7-10 days after receiving deposit)

· Corrosion resistance

· Can be recycled and reused

· Mill test certification

· Professional Service

· Competitive pricing

Product Specifications:

No. | Dimensions | Weight (Kg/m) | ||

Height (mm) | Width (mm) | Thickness (mm) | ||

5# | 50 | 37 | 4.5 | 5.438 |

6.3# | 63 | 40 | 4.8 | 6.634 |

8# | 80 | 43 | 5 | 8.045 |

10# | 100 | 48 | 5.3 | 10.007 |

12# | 120 | 53 | 5.5 | 12.059 |

14A# | 140 | 58 | 4.9 | 14.535 |

14B# | 140 | 60 | 8.0 | 16.733 |

16A# | 160 | 63 | 6.5 | 17.24 |

16B# | 160 | 65 | 8.5 | 19.752 |

18A# | 180 | 68 | 7.0 | 20.174 |

18B# | 180 | 70 | 9.0 | 23 |

20A# | 200 | 73 | 7.0 | 22.637 |

20B# | 200 | 75 | 9.0 | 22.777 |

22A# | 220 | 77 | 7.0 | 24.999 |

22B# | 220 | 79 | 9.0 | 28.453 |

25A# | 250 | 78 | 7.0 | 27.41 |

25B# | 250 | 80 | 9.0 | 31.335 |

28A# | 280 | 82 | 7.5 | 31.427 |

28B# | 280 | 84 | 9.5 | 35.823 |

30A# | 300 | 85 | 7.5 | 34.463 |

30B# | 300 | 87 | 9.5 | 39.173 |

32A# | 320 | 88 | 8 | 38.083 |

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered byOKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will begin production. The specific shipping date is dependent upon international and government factors, but is typically 7 to 10 workdays.

Q4: What makes stainless steel stainless?

A4: Stainless steel must contain at least 10.5 % chromium. It is this element that reacts with the oxygen in the air to form a complex chrome-oxide surface layer that is invisible but strong enough to prevent further oxygen from "staining" (rusting) the surface. Higher levels of chromium and the addition of other alloying elements such as nickel and molybdenum enhance this surface layer and improve the corrosion resistance of the stainless material.

Q5: Can stainless steel rust?

A5: Stainless does not "rust" as you think of regular steel rusting with a red oxide on the surface that flakes off. If you see red rust it is probably due to some iron particles that have contaminated the surface of the stainless steel and it is these iron particles that are rusting. Look at the source of the rusting and see if you can remove it from the surface.

Images:

- Q: What are the different methods for surface preparation of steel channels?

- There are several different methods for surface preparation of steel channels, each with its own advantages and suitability for specific applications. Some of the common methods include: 1. Mechanical Cleaning: This method involves using abrasives such as sandpaper, wire brushes, or grinding wheels to physically remove any loose rust, scale, or old coatings from the surface of the steel channels. Mechanical cleaning is typically done manually or with the help of power tools and is a cost-effective way to prepare the surface. 2. Chemical Cleaning: This method involves using chemicals to dissolve or loosen contaminants on the steel channel's surface. Acid-based cleaners are commonly used, such as phosphoric acid or citric acid, which can effectively remove rust and other surface contaminants. Chemical cleaning is often used for removing heavy rust or scale buildup. 3. Power Tool Cleaning: This method involves using power tools like power sanders, rotary hammers, or wire brushes to remove loose rust, scale, or old paint from the steel channel's surface. Power tool cleaning is usually faster and more efficient than manual methods, making it ideal for larger surfaces or areas with heavy contamination. 4. High-Pressure Water Cleaning: This method involves using high-pressure water jets to remove loose rust, scale, or old coatings from the steel channel's surface. High-pressure water cleaning is effective for removing surface contaminants without causing damage to the metal. It is commonly used in industrial settings where large areas need to be cleaned quickly and efficiently. 5. Abrasive Blasting: This method involves using compressed air or water to propel abrasive materials, such as sand, grit, or steel shot, onto the steel channel's surface. Abrasive blasting is highly effective in removing rust, scale, and old coatings, leaving a clean and profiled surface ready for further treatment or coating. It is commonly used in industries where a high-quality surface finish is required. It is important to select the appropriate method for surface preparation based on the condition of the steel channel, the desired surface finish, and the specific requirements of the application. Proper surface preparation is crucial for ensuring good adhesion of coatings and extending the lifespan of the steel channels.

- Q: What are the weight calculations for steel channels?

- To determine the weight of steel channels, one can utilize the following formula: Weight can be found by multiplying the cross-sectional area with the density of steel. The cross-sectional area of a steel channel can be determined by multiplying the width (W), height (H), and thickness (T) of the web. In the case of tapered flanges, the average width (Wa) of the flanges should be employed. To calculate the cross-sectional area, add twice the average width of the flanges to the width, multiply the sum by the height, and add the product of the thickness and width. The density of steel typically measures approximately 7,850 kilograms per cubic meter (kg/m³). Hence, the weight of the steel channel can be established by multiplying the cross-sectional area by the density of steel. To ensure accurate weight calculations, it is crucial to employ consistent units for all measurements, such as meters or millimeters. Additionally, it is advisable to verify the specific dimensions and specifications of the steel channel being utilized, as they may vary.

- Q: What are the different methods for protecting steel channels from water intrusion?

- There are several methods for protecting steel channels from water intrusion, depending on the specific requirements and conditions. Here are some common methods: 1. Coatings: Applying a protective coating to the surface of steel channels is one of the most effective methods for preventing water intrusion. Coatings such as epoxy, polyurethane, or zinc-rich paints create a barrier that prevents water from coming into contact with the steel, thus reducing the risk of corrosion. 2. Galvanization: Galvanizing steel channels involves coating them with a layer of zinc, which acts as a sacrificial barrier against corrosion. This method is particularly effective in environments with high humidity or exposure to corrosive substances. 3. Waterproofing membranes: The application of waterproofing membranes on the surface of steel channels can prevent water from seeping into the material. These membranes can be made of various materials such as bitumen, rubber, or PVC, providing a protective barrier against water intrusion. 4. Sealants: Using sealants, such as silicone or polyurethane caulk, can effectively seal gaps or joints in steel channels, ensuring water does not penetrate these vulnerable areas. It is essential to regularly inspect and replace sealants to maintain their effectiveness. 5. Drainage systems: Installing a proper drainage system around steel channels can help divert water away from the structure. This can be achieved through the use of gutters, downspouts, and proper grading to ensure water flows away from the channels, reducing the risk of water intrusion. 6. Maintenance and inspection: Regular maintenance and inspection of steel channels are crucial for identifying any signs of water intrusion or corrosion. Promptly addressing any issues, such as repairing damaged coatings or sealants, can prevent further damage and ensure the long-term protection of the channels. It is important to note that the effectiveness of these methods may vary depending on factors such as the specific environment, exposure to water, and the quality of materials used. Consulting with professionals and adhering to industry standards and guidelines is highly recommended to ensure the most suitable method is employed for protecting steel channels from water intrusion.

- Q: Are steel channels suitable for data center construction?

- Data center construction can benefit greatly from the use of steel channels. These channels, also known as C-channels, possess the necessary qualities of strength, stability, and flexibility required for such projects. Their durability and ability to withstand heavy loads make them a popular choice for framing walls, ceilings, and floors. The advantages of using steel channels in data center construction are numerous. Firstly, their exceptional load-bearing capabilities enable them to support the weight of server racks, equipment, and infrastructure. In data centers with high equipment density and significant server and networking device weights, this is of utmost importance. Furthermore, steel channels contribute to the structural stability of a data center, ensuring its security and strength. They are resistant to bending and buckling, providing a solid framework capable of withstanding both internal and external forces. This is particularly beneficial in areas prone to seismic activities or extreme weather conditions. In addition, steel channels allow for easy installation of various utilities necessary in data centers, such as electrical wiring, cable trays, and cooling systems. They can be designed with pre-punched holes or slots, simplifying the routing of cables and pipes throughout the facility. Moreover, steel channels offer versatility in design and construction. They can be easily modified and adjusted to meet specific layout requirements, facilitating efficient use of space and flexibility for future expansions or modifications. This adaptability is crucial in data centers where technology and infrastructure needs are constantly evolving. In conclusion, steel channels are undeniably suitable for data center construction. Their strength, stability, flexibility, and versatility make them an ideal choice for creating a robust and efficient infrastructure to support the critical operations of a data center.

- Q: How much is the load-bearing capacity of No. 10 I-beam per metre?

- National Standard No. 10 I-beam is 11.261kg/ meters; 6 meters long weight is 67.566kg

- Q: Can steel channels be used for fencing applications?

- Yes, steel channels can be used for fencing applications. Steel channels are strong and durable, making them suitable for various fencing purposes. They can be used to create the framework for a fence, providing stability and support. Steel channels can also be used as posts or rails in fencing systems, offering strength and rigidity. Additionally, steel channels can be easily welded together, allowing for customization and the creation of different fencing designs. Overall, steel channels provide a reliable and long-lasting option for fencing applications.

- Q: Can steel channels be used in load-bearing applications?

- Yes, steel channels can be used in load-bearing applications. Steel channels are commonly used in construction and structural engineering for their strength and durability. They provide structural support and can handle heavy loads, making them suitable for load-bearing applications such as beams, columns, and frames.

- Q: What are the different methods for protecting steel channels from corrosion?

- There are multiple techniques available to safeguard steel channels against corrosion. Here are a few of the most prevalent options: 1. Application of a protective coating: A highly effective approach involves applying a protective coating onto the surface of the steel channels. This can be accomplished using various methods such as paints, epoxy coatings, or galvanizing. Coatings act as a physical barrier, preventing direct contact and corrosion between the steel and the corrosive elements present in the environment. 2. Cathodic protection: Another method involves employing a sacrificial metal or an impressed current to shield the steel channels. By connecting sacrificial metals like zinc or magnesium to the channels, these metals, which are more reactive than steel, will corrode in place of the channels. Impressed current systems, on the other hand, utilize an external power source to generate an electric current that counteracts the corrosion process. 3. Use of corrosion inhibitors: Chemicals known as corrosion inhibitors can be applied to the steel channels to slow down or prevent corrosion. These inhibitors function by creating a protective layer on the channel's surface, hindering the reaction between the steel and the corrosive elements. 4. Considerations in design: Implementing proper design and construction practices can also contribute to the protection of steel channels from corrosion. This includes ensuring adequate drainage and ventilation to minimize moisture accumulation, avoiding the presence of crevices and areas prone to water buildup, and using materials that are less susceptible to corrosion in corrosive environments. 5. Regular maintenance: Routine inspections and maintenance activities, such as cleaning and removing any accumulated debris or dirt, play a crucial role in identifying and addressing potential corrosion issues at an early stage. This may involve reapplying coatings, repairing damaged areas, or replacing corroded sections of the steel channels. It is important to acknowledge that the selection of a protection method depends on factors such as the specific environment, the anticipated service life of the channels, and budgetary constraints. Seeking guidance from corrosion experts or professionals in the field can assist in determining the most suitable method for safeguarding steel channels from corrosion in a particular application.

- Q: What are the different surface coatings available for steel channels?

- There are several different surface coatings available for steel channels, including galvanized coatings, zinc coatings, epoxy coatings, powder coatings, and paint coatings.

- Q: What are the different methods of strengthening steel channels?

- There are several methods used to strengthen steel channels, including heat treatment, cold working, and alloying. Heat treatment involves subjecting the steel to high temperatures and then cooling it rapidly, which alters its microstructure and increases its strength. Cold working, on the other hand, involves deforming the steel at room temperature through processes like rolling or drawing, which also enhances its strength. Alloying refers to adding other elements to the steel, such as carbon or chromium, to improve its properties and make it stronger.

Send your message to us

JIS & G/B Standard Steel Channel Module

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 2000 PCS

- Supply Capability:

- 40000 PCS/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords