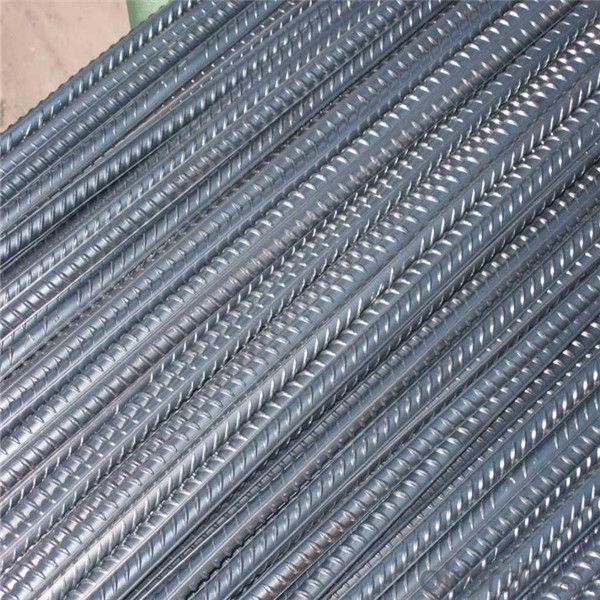

HRB400 HRB 500 steel rebar Good quality

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m.t.

- Supply Capability:

- 19863 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Deformed Steel bar is a common steel reinforcing bar, used in reinforced concrete and reinforced masonry structures.

It is formed from mild steel, and is given ribs for better frictional adhesion to the concrete. The Deformed Steel bar is

an iron rod , a weldable plain reinforcing steel bar, and can be used as well for steel meshes.

Our Advantage:

High quality steel products from 1 class mills in China

Reasonable price

Professionalism of the products

On-time delivery

Complete documents and certificates

Sincere service to meet our clients' requirements

Product Description :

Chemical composition (%): | Steel | C | Si | Mn | P | S | Ceq | ||||

HRB335 |

0.25 |

0.80 |

1.60 |

0.045 |

0.045 | 0.52 | |||||

HRB400 | 0.54 | ||||||||||

HRB500 | 0.55 | ||||||||||

Mechanical properties | Steel | Rel/ MPa | Rm/ MPa | A/ % | Agt/ % | ||||||

≥ | |||||||||||

HRB335 | 335 | 455 | 17 |

7.5 | |||||||

HRB400 | 400 | 540 | 16 | ||||||||

HRB500 | 500 | 630 | 15 | ||||||||

Package: | Standard export packing or as customer's request | ||||||||||

Application: | Construction, building, bridge, road. ect | ||||||||||

Payment terms | 1).100% irrevocable L/C at sight. | ||||||||||

Delivery time | 15-30 days after receipt of L/C or deposit by T/T | ||||||||||

Features

1、Pure steel quality, stable chemical contents, small tolerance.

2、Constant Quality, good drawing performance.

3、High dimension accuracy degree, accuracy degree of Level C up to 80%, smooth surface, less scale, easy to be pickled.

4、Automatic bundling with 4 lines by Machine in tidy and good looks

5、Big high quality percentage, small coil percentage, and heavy coil weight for Hard Coil.

6、High sorbitizing percentage.

Packing:

In bundles, each bundle weight 3.5 tons. Load by container or by bulk verssel.

Our service

(1) We cooperate with famous factories with advanced equipment and well trained workers.

(2) We can provide factory price with trading company service.

(3) We continuously work on the improvement of our processes, guaranteeing consistently high standards

of quality to keep none compensation.

(4) We guarantee 24 hours response and 48 hours solution providing service.

(5) We accept small order quantity before formal cooperation.

(6) We deliver the agreed quality at the agreed time, reacting to changes in customer wishes in a flexible way.

(7) Due to our volume and selling power, we have excellent freight rates with shipping lines.

(8) We strive to always be fair and honest in our dealings with customers.

(9) We strive to work together with customers to achieve much more than we can achieve alone.

(10) Through our passion and commitment we aim to be a market leader in all our key markets. To maintain

our position as market leader we must continue to add value in all that we do.

FAQ:

1.Q: What's your MOQ(minimum order quantity)?

A: One full container, mixed acceptable .

2. Q: What's your packing methods?

A: Packed in bundle or bulk ..

3. Q: How can I buy CNBM products in my country?

A:Please send us an inquiry or email ,we will reply to you if there is distributor in your country

4. Q: Can we visit your factory?

A: Warmly welcome. Once we have your schedule, we will arrange the professional sales team to follow up your case.

5. Q: How long does it take to get the product if i place an order?

A:With the process of your requirements,we will pack and deliver in 3-7 days. If it is by sea shipment,it will take 15-45 days depending on different locations

- Q: What are the international standards for steel rebars?

- The international standards for steel rebars are set by various organizations and bodies such as the International Organization for Standardization (ISO), American Society for Testing and Materials (ASTM), and the European Committee for Standardization (CEN). ISO provides standards for steel rebars under ISO 15630, which covers both hot-rolled and cold-worked rebars. This standard defines the requirements for the chemical composition, mechanical properties, dimensions, and tolerances of rebars used in reinforced concrete structures. ASTM has developed several standards for steel rebars, including ASTM A615/A615M and ASTM A706/A706M. ASTM A615/A615M covers deformed and plain carbon-steel rebars for concrete reinforcement, specifying the chemical composition, mechanical properties, dimensions, and marking requirements. ASTM A706/A706M focuses on low-alloy steel rebars with improved weldability, suitable for use in concrete structures where welding is required. In Europe, CEN has established the Eurocode 2 (EN 1992-1-1) as the primary standard for steel rebars. This code provides design rules for the structural use of concrete and includes guidelines for the selection and use of rebars. Additionally, CEN has also developed EN 10080, which specifies the requirements for steel rebars for concrete reinforcement, covering chemical composition, mechanical properties, dimensions, and tolerances. These international standards ensure the quality and consistency of steel rebars used in construction projects worldwide. Compliance with these standards helps to ensure the safety and reliability of reinforced concrete structures by providing guidelines for material properties, manufacturing processes, and quality control measures.

- Q: What is the relationship between steel structure and thread steel?

- Thread steel is usually used in embedded parts of steel structures, sometimes in civil engineering units, and sometimes in steel structural units. How to divide the owner's list?

- Q: What is the effect of exposure to chemicals on steel rebars?

- Exposure to chemicals can have various effects on steel rebars depending on the specific chemical involved. Corrosive chemicals, such as acids or salts, can cause corrosion and weaken the steel rebars over time. This can compromise the structural integrity of reinforced concrete structures, leading to potential safety hazards. On the other hand, some chemicals like epoxy or protective coatings can be applied to steel rebars to enhance their resistance to corrosion and extend their lifespan. Overall, the effect of exposure to chemicals on steel rebars can range from degradation to protection, highlighting the importance of proper material selection and maintenance in construction projects.

- Q: Can steel rebars be used in wind turbine tower construction?

- Steel rebars are indeed utilized in the construction of wind turbine towers. In the construction industry, steel rebars are frequently employed to reinforce concrete structures. Wind turbine towers typically consist of reinforced concrete for both the foundation and the tower structure. By integrating steel rebars, the concrete's strength and durability are enhanced, enabling it to withstand the wind turbine's exerted loads and forces. The rebars effectively reinforce the concrete, ensuring the even distribution of loads throughout the tower structure, thereby guaranteeing its stability and structural integrity. Consequently, steel rebars hold significant importance in wind turbine tower construction and are commonly employed in this particular application.

- Q: How do steel rebars prevent concrete from cracking?

- Steel rebars prevent concrete from cracking by providing tensile strength to the structure. When concrete is subjected to external forces or loads, it tends to crack due to its low tensile strength. However, by reinforcing it with steel rebars, the concrete becomes more resistant to cracking. The rebars act as structural reinforcement, absorbing the tensile forces and distributing them throughout the concrete, preventing cracks from forming and ensuring the overall stability and durability of the structure.

- Q: What is the role of steel rebars in pile foundation construction?

- The role of steel rebars in pile foundation construction is to reinforce the concrete and provide additional strength and structural integrity to the piles. The rebars are placed within the concrete to resist tension and compression forces, preventing cracking and ensuring the stability and durability of the pile foundation.

- Q: How are steel rebars identified and marked?

- Steel rebars are identified and marked through various methods including embossed markings, painted markings, and tagging systems. These identification marks typically include relevant information such as the grade of steel, manufacturer's logo, batch number, and bar size.

- Q: Are steel rebars affected by magnetic fields?

- Yes, steel rebars are affected by magnetic fields. Steel is a ferromagnetic material, which means it can be magnetized and is attracted to magnets. Thus, the presence of a magnetic field can cause steel rebars to experience magnetic forces or become magnetized themselves.

- Q: What is the recommended diameter of steel rebars for column reinforcement?

- The recommended diameter of steel rebars for column reinforcement varies depending on factors such as the column size, design specifications, and structural requirements. Generally, rebars with diameters ranging from 12mm to 40mm are commonly used for column reinforcement. It is important to consult structural engineers or refer to local building codes and standards to determine the specific recommended diameter for column reinforcement in a particular construction project.

- Q: What are the safety precautions when handling steel rebars?

- When handling steel rebars, it is important to follow several safety precautions. Firstly, always wear appropriate personal protective equipment (PPE) such as gloves, goggles, and steel-toed boots to protect yourself from potential injuries. Secondly, ensure that the work area is clear of any debris or obstacles that may cause trips or falls. Additionally, use proper lifting techniques and team lifting when necessary to avoid strain or back injuries. It is crucial to be aware of the weight and length of the rebars being handled to prevent them from falling or causing accidents. Lastly, remember to store and stack the rebars securely to prevent them from toppling over and causing injuries.

Send your message to us

HRB400 HRB 500 steel rebar Good quality

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m.t.

- Supply Capability:

- 19863 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords