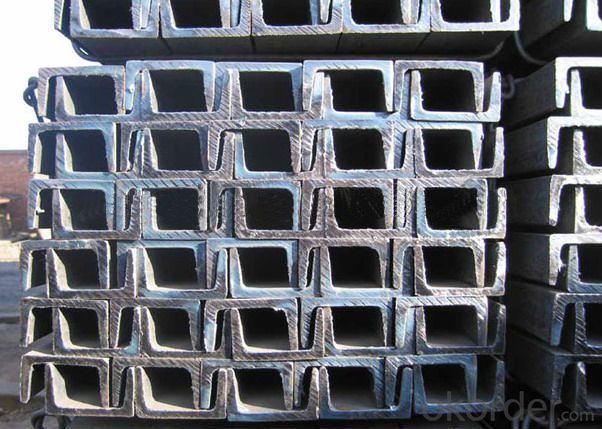

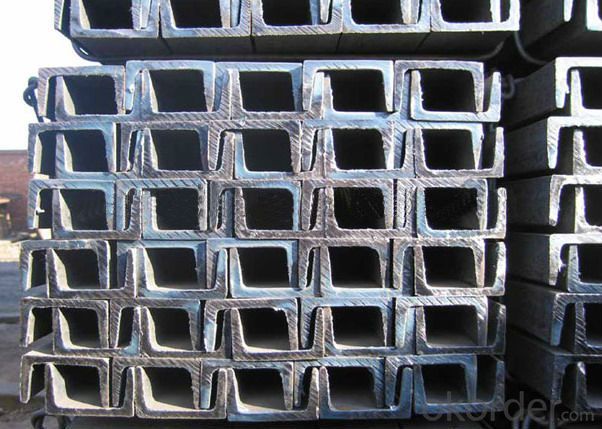

Hot Rolled Alloy U Channel Steel ASTM,JIS,GB Standard

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 PCS

- Supply Capability:

- 38000 PCS/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Hot Rolled Alloy U Channel Steel ASTM,JIS,GB Standard Details

| Standard: | AISI,ASTM,BS,DIN,GB,JIS | Dimensions: | 50*37*4.5-400*104*14.5mm | Grade: | Q235/345,SS400,A36/572/992,Gr50,S235JRG2,S235/275/335JR,ect |

| Place of Origin: | Tianjin China (Mainland) | Brand Name: | CNBM | Model Number: | RGTS-u channel |

| Shape: | U Channel | Application: | construction material or bracket | Perforated Or Not: | Not Perforated |

| Other goods: | C channel steel | Experience: | 15years | Spot goods: | Regular size have stock |

| Inspection: | SGS, BV | Delivery condition: | EXW,FOB,CFR,CIF | Quality: | Prime |

| Weight: | 5.438-71.488kg/m | Thickness tolerance: | +/-0.05mm | Model: | 5#-40# |

| Product: | channel steel |

Packaging & Delivery

| Packaging Detail: | In four circles of 6.5 steel wire rods for 6 meter goods. In six circles of 6.5 steel wire rods for 12 meter goods. Each bundle not exceeding 4mt. Also can be packing as customer's requirements |

| Delivery Detail: | within 15-30 days after receiving original L/C or deposit |

Hot Rolled Alloy U Channel Steel ASTM,JIS,GB Standard Specification

Size | 50mm*50mm-400mm*400mm |

Wall thickness | 1.5mm-25mm |

Length | 1m-12m ,by customer’s requirements |

International Standard | ISO 9001-2008 / ISO 630 / JIS / ASTM |

Standards | ASTMA53/ASTM A573/ASTM A283 /BS1387-1985/ GB/T3091-2001,GB/T13793-92, ISO630/E235B/ JIS G3101/JIS G3131/JIS G3106/ |

Materials | Q195,Q215,Q235B,Q345B,S235JR/S235/S355JR/S355SS440/SM400A/SM400B |

Product Category | Metallurgy, Mineral &Energy |

Technique | HOT ROLLED |

Packing | 1.Big OD: in bulk 2.Small OD: packed by steel strips 3.woven cloth with 7 slats 4.according to the requirements of customers |

Usage | Mechanical & manufacture, Steel structure,Shipbuilding, Bridging, Automobile chassis |

Main market | Middle East, Africa, Asia and America ,Australia |

Country of origin | China |

Productivity | 5000 Metric Tons per Month |

Remark | Payment terms :T/T ,L/C Terms of trade :FOB ,CFR,CIF ,DDP,EXW Minimum order : 20 tons Lead time :on or before 10-30 working days . |

Another Name | u channel steel , channel steel, steel channel |

Surface processing | Galvanized, coated, or as your request |

Technical | Hot rolled mild steel |

Other Service | Customized Sizes, Galvanized And punching |

Hot Rolled Alloy U Channel Steel ASTM,JIS,GB Standard Pictures

- Q: Can steel channels be used for guardrail systems?

- Indeed, guardrail systems can make effective use of steel channels. Given their robustness and endurance, steel channels frequently find application in construction and infrastructure endeavors. They offer a stable base and reinforcement for guardrail systems, thereby guaranteeing the safety and safeguarding of both pedestrians and vehicles. The fabrication and installation of steel channels are uncomplicated, rendering them a prudent and economical option for guardrail systems. Furthermore, steel channels exhibit remarkable resilience against inclement weather and corrosion, rendering them ideal for extended use in outdoor settings. In conclusion, steel channels are a dependable and widely employed material for the construction of guardrail systems.

- Q: Can steel channels be used in historical restoration projects?

- Indeed, historical restoration projects can utilize steel channels. These channels possess versatility and durability, rendering them appropriate for various purposes, such as historical restoration. They serve to strengthen and uphold structures, replace worn-out or impaired components, and safeguard the historical authenticity of edifices and landmarks. Moreover, steel channels can be tailored to mirror the original design and appearance of the historical structure, guaranteeing flawless integration. Furthermore, the robustness and endurance of steel make it an optimal substance to withstand the trials of time, thereby securing the perpetuity and sustainability of the refurbished historical site.

- Q: Are steel channels suitable for use in the construction of platforms or raised floors?

- Steel channels are a suitable option for constructing platforms or raised floors. They are frequently utilized in construction due to their durability, strength, and versatility. These channels provide exceptional support and stability, which makes them ideal for creating robust and dependable platforms or raised floors. One of the key advantages of steel channels is their ability to withstand heavy loads without bending or warping. They can support the weight of machinery, equipment, or individuals without compromising the structural integrity of the platform or raised floor. This feature has made them a popular choice in diverse settings, including industrial facilities, warehouses, factories, and even residential or commercial buildings. Moreover, steel channels possess excellent resistance against fire, corrosion, and pests, ensuring long-term durability and safety. They can be easily customized to meet specific design requirements, enabling flexibility in creating platforms or raised floors of various sizes and shapes. Additionally, steel channels can be seamlessly integrated with other construction materials, such as concrete or wood, to enhance strength and stability. They can also be combined with other structural components like beams or columns to establish a comprehensive and reliable support system. In summary, steel channels offer numerous benefits that make them highly suitable for constructing platforms or raised floors. Their strength, durability, versatility, and compatibility with other materials make them a dependable choice for ensuring stability and safety in such structures.

- Q: Can steel channels be used for window frames?

- Yes, steel channels can be used for window frames. Steel channels provide excellent strength, durability, and resistance to corrosion, making them suitable for window frames that require stability and longevity.

- Q: Can steel channels be used for creating support structures for conveyor systems?

- Yes, steel channels can be used for creating support structures for conveyor systems. Steel channels offer high strength and durability, making them suitable for supporting heavy loads and providing stability to the conveyor system. Additionally, steel channels can be easily fabricated and customized to fit specific requirements, making them a popular choice for constructing support structures in conveyor systems.

- Q: Can steel channels be used for roof structures?

- Yes, steel channels can be used for roof structures. Steel channels are strong and durable, making them suitable for supporting the weight of a roof. They can provide structural stability and support, making them a popular choice in construction for various types of roofs.

- Q: Are steel channels suitable for the mining manufacturing industry?

- Steel channels are an ideal choice for the mining manufacturing industry. They are widely used in various industries, including mining, because of their exceptional strength and durability. In the mining industry, where rugged conditions and intensive use are common, heavy-duty equipment and machinery are required. Steel channels, being made of a strong and sturdy material, can provide the necessary support and structural integrity to withstand the demanding requirements of the mining manufacturing industry. Furthermore, steel channels offer flexibility in terms of design and configuration, making them suitable for a wide range of applications within the mining industry. They can be used to construct frameworks, support structures, conveyor systems, and other equipment essential for mining operations. Moreover, steel channels have a high load-bearing capacity, which is crucial in the mining industry where heavy loads and vibrations are prevalent. They can efficiently distribute weight and handle stress, ensuring the safety and dependability of mining equipment and structures. Additionally, steel channels are resistant to corrosion, making them well-suited for use in the mining industry where exposure to moisture, chemicals, and other corrosive substances is common. This corrosion resistance extends the lifespan of the equipment, reducing maintenance and replacement costs. In conclusion, steel channels are an excellent choice for the mining manufacturing industry due to their strength, durability, versatility, and resistance to corrosion. They provide the necessary support and structural integrity needed for heavy-duty mining equipment and structures, making them a reliable option for various applications within the industry.

- Q: Can steel channels be used in cold storage facilities?

- Yes, steel channels can be used in cold storage facilities. Steel is a strong and durable material that can withstand the low temperatures and provide structural support for the storage facility. It is commonly used in the construction of cold storage buildings due to its resistance to corrosion and ability to maintain stability in cold environments.

- Q: Can steel channels be used in the construction of agricultural buildings?

- Yes, steel channels can be used in the construction of agricultural buildings. Steel channels are strong, durable, and can withstand heavy loads, making them suitable for various structural applications, including the construction of agricultural buildings. They are commonly used for framing, support beams, and trusses in agricultural structures such as barns, warehouses, and storage buildings. Steel channels offer excellent resistance against corrosion, pests, and fire, making them a reliable choice for agricultural construction projects.

- Q: What are the typical lengths of steel channels?

- Steel channels come in a range of lengths depending on the manufacturer and their intended purpose. Generally, you can find them in standard sizes between 20 feet (6.1 meters) and 40 feet (12.2 meters). These standard lengths are commonly utilized in construction projects for structural support, framing, and bracing. Moreover, manufacturers may offer tailored cutting services to accommodate specific length requirements for individual projects.

Send your message to us

Hot Rolled Alloy U Channel Steel ASTM,JIS,GB Standard

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 PCS

- Supply Capability:

- 38000 PCS/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords