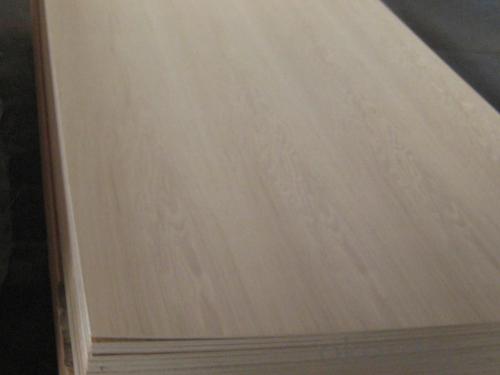

Plywood for Sale - Hot Press Plywood Two Times Hot Press Made in China

- Loading Port:

- Lianyungang

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description

Face/Back | Teak ,Natural Ash,Sapeli, Red Oak, White Oak, steam Beech, | |

Core: | Poplar core & Harewood core, or on requirment | |

Grade: | AAA, AA, A | |

Glue: | MR/E0/E1/E2 | |

Size(mm) | 1220×2440mm, 915×2135mm | |

Thickness(mm) | 2.0-18.0mm | |

Moisture | 9%-14% at time of shipment | |

Thickness tolerance | ±0.2mm to ±0.3mm | |

Packing | Inter packing:0.2mm plastic; Ourter packing:bottom is pallets, covered with plastic film,around is carton or plywood, strenghthen by steel or iron 3*6 | |

Quantity | 20GP | 8pallets/21M3 |

40GP | 16pallets/42M3 | |

40HQ | 18pallets/53M3 | |

Usage | Usage adequate for making furniture or construction, package or industry, | |

Minimum Order | 1×20GP | |

Payment | TT or L/C at sight | |

Delivery Time | Within 35 days receiving deposit or original L/C at sight | |

Features

1 wear-resistant,anti-cracking,anti-acid and alkaline-resistant

2 no color cotamination between the concrete and shuttering board

3 can be cut int samll size for reusing.

Specifications

Bintangor faced poplar core 1/4 inch plywood

glue: E1 E2

material : poplar, pine

usage : for furniture and construction

- Q: What is the composition of the plywood?

- Plywood usually refers to the plywood or multi-layer board, that is, with the same thickness of two or more layers of veneer plus glue from high temperature suppression

- Q: Class I resistant weather plywood Class II water resistant plywood

- slab molding (mixing resin and additives pavement), under hot pressure, so that cellulose and Hemicellulose and lignin plasticized to form a plate.

- Q: Plywood can improve timber utilization and is a major way to save wood.

- side panels are made of pure solid wood, do not use any other form of wood-based panels

- Q: Plywood is generally used in applications where the strength and stability of the material are relatively high

- For example: Yunshan plywood is a soft Murray plywood, it can be used for housing flooring, walls and ceiling, coated surface can also be sprayed after the coating.

- Q: Further processing of the plywood

- plywood treated plywood plywood used in the manufacturing process or after manufacturing to deal with the physical properties of coupons.

- Q: How is the current market outlook for plywood?

- to achieve cumulative product sales of 96,534,099 thousand yuan, an increase of 48.87% over the previous year

- Q: Wood board, plywood, MDF What is the difference

- Can be single-sided sanding, double-sided sanding or both sides are not sanding.

- Q: The Preparation of plywood ingredients

- central layer central ply plywood center layer, the other layers are symmetrically arranged on both sides of it.

- Q: What are the defects in plywood material?

- Fracture split, end split The fiber is separated in the direction of the grain, usually starting from one end and extending through the thickness of the morning plate

- Q: What are the defects of the plywood?

- unsound section unsound knots The decaying part of a section of a child does not exceed 1/3 of the knot.

Send your message to us

Plywood for Sale - Hot Press Plywood Two Times Hot Press Made in China

- Loading Port:

- Lianyungang

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords