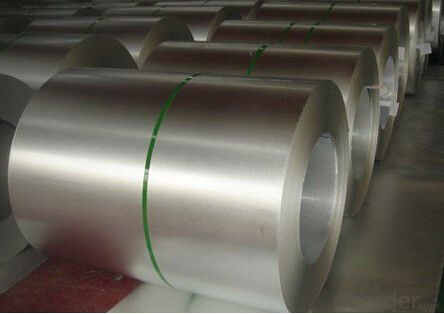

Hot Dipped Galvanized Steel Coil (DC53D+Z, St05Z, DC53D+ZF)

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description Info.

Model NO.:DC53D+Z, St05Z, DC53D+ZF

Surface Treatment:Galvanized

Technique:Cold Rolled

Standard:ASTM, JIS, GB, AISI, DIN, BS

Steel Grade:DC53D+Z, St05z, DC53D+Zf

Commodity Name:Hot Dipped Galvanized Steel Coil

Thickness:0.3-3.0mm

Width:800-1830mm

Zinc Coating:40-275g

Export Markets:Global

Additional Info.

Trademark:Helio

Packing:Inside: Moisture-Proof Paper/Outside: Steel Plate

Standard:AS buyer requirement

Origin:China

Production Capacity:5000tons Per Month

Product Description

Hot Dipped Galvanized Steel Coil

Hot Dipped Galvanized Steel Coil (DC53D+Z, St05Z, DC53D+ZF)

Brief Introduction:

Commodity name : Hot Dipped Galvanized Steel Coil

Standard we can provide: AISI ASTM BS DIN GB JIS

Grade : DC53D+Z,St05Z,DC53D+ZF

Zinc Coating:40g-275g/m2

Size we can provide:

Size Range: CRC substrate Thickness: 0.3-3.0mm

CRC substrate Width: 800-1830mm

HRC substrate Thickness:1.8-2.8mm

HRC substrate Width:900-1500mm

FAQ

1.What's your MOQ?

25MT, it is for one container.

2.Do you have QC teams?

Yeah, sure, our QC team is very important, they will keep the quality control for our products.

3. What's your normal delivery time?

Our delivery time about 10-20days for standard sizes, if you have other requirements like hardness and width ,it is about 20-40days. But don't worry ,we also try our best for the delivery time ,because time longer and our cost is higher.

4.Are the products tested before shipping?

Yes, all of our PPGI and GI was qualified before shipping. We test every batch every day.

- Q: How do steel coils contribute to seismic resistance in structures?

- Steel coils contribute to seismic resistance in structures by providing strength and flexibility. The coiled shape allows the steel to absorb and dissipate the energy generated during seismic events, thereby reducing the impact on the structure. This increased flexibility helps prevent the structure from collapsing under the stress of seismic forces, making it more resistant to earthquakes.

- Q: What are the common applications of pre-painted steel coils?

- Pre-painted steel coils, also known as pre-coated steel coils or color coated steel coils, are widely used in various industries due to their versatility and durability. Some of the common applications of pre-painted steel coils include: 1. Construction: Pre-painted steel coils are extensively used in the construction industry for roofing, wall cladding, and building panels. The color options available in pre-painted steel coils allow architects and designers to create aesthetically pleasing structures. 2. Automotive: Pre-painted steel coils are used in the automotive industry for manufacturing car bodies, interior panels, and various other parts. The corrosion resistance and excellent finish provided by pre-painted steel coils make them a preferred choice in this industry. 3. Appliances: Many household appliances like refrigerators, washing machines, and air conditioners use pre-painted steel coils for their outer panels. The attractive colors and textures available in pre-painted steel coils help enhance the appearance of these appliances. 4. Electronics: Pre-painted steel coils are also used in the electronics industry for manufacturing cabinets and casings of electronic devices like computers, televisions, and audio systems. The protective coating on pre-painted steel coils helps protect the electronic components from environmental factors. 5. Furniture: Pre-painted steel coils find applications in the furniture industry for manufacturing cabinets, shelves, and other similar products. The wide range of colors and finishes available in pre-painted steel coils allows furniture manufacturers to create visually appealing and durable products. 6. Signage and Advertising: Pre-painted steel coils are commonly used in signage and advertising applications for manufacturing display boards, billboards, and signages. The vibrant colors and weather-resistant properties of pre-painted steel coils make them suitable for outdoor use. 7. Industrial Equipment: Pre-painted steel coils are utilized in the manufacturing of industrial equipment such as storage tanks, HVAC systems, and machinery components. The corrosion resistance and high strength of pre-painted steel coils make them suitable for these demanding applications. In summary, pre-painted steel coils have a wide range of applications in various industries such as construction, automotive, appliances, electronics, furniture, signage, and industrial equipment. Their durability, corrosion resistance, and aesthetic appeal make them a popular choice for manufacturers across different sectors.

- Q: What are the challenges in coil recoiling?

- Coil recoiling, also known as coil winding, can pose several challenges depending on the specific application and requirements. Some of the common challenges in coil recoiling include: 1. Precision and accuracy: Achieving precise and accurate winding is crucial for optimal coil performance. Maintaining consistent tension throughout the winding process, ensuring proper alignment, and controlling the speed are essential to avoid variations in the coil's electrical properties. 2. Wire management: Handling the wire during the recoiling process can be challenging. The wire may be delicate, prone to tangling, or have specific handling requirements, such as being magnetically or thermally sensitive. Proper wire management techniques, such as tension control, wire guide systems, and spooling mechanisms, need to be employed to prevent wire damage and ensure uniform winding. 3. Space constraints: In many applications, coils need to fit within specific space limitations. Designing and winding coils to fit compact spaces can be challenging, especially when considering the required number of turns, wire size, insulation, and any additional components or structures that may need to be incorporated. 4. Material selection: Selecting the appropriate wire and insulation material is crucial for coil performance and longevity. Factors such as electrical conductivity, thermal properties, mechanical strength, and chemical resistance need to be considered to ensure the coil can withstand the operating conditions and environmental factors it will be exposed to. 5. Heat dissipation: Coils often generate heat during operation, especially in high-power applications. Efficient heat dissipation is essential to prevent overheating and ensure the longevity of the coil. Designing the coil with proper ventilation, utilizing cooling mechanisms, or integrating heat sinks are some of the techniques used to address this challenge. 6. Quality control: Ensuring consistent quality in coil recoiling can be challenging due to factors such as variations in wire properties, operator skill, equipment calibration, and environmental conditions. Implementing robust quality control measures, such as conducting regular inspections, performing electrical tests, and monitoring process parameters, is necessary to maintain consistent coil performance. Overall, coil recoiling requires attention to detail, precision, and adherence to specific requirements to overcome the challenges and produce high-quality coils that meet the desired performance criteria.

- Q: Which one has more electrical resistivity? Wood or steel? And why?I know that the resistivity depends on the material of the conductor, but i want a perfect explaination please.Thnx in advance :)

- Steel is a conductor while wood is an insulator. There are no free electrons available in wood for conduction of electricity to take place. So wood has more electrical resistivity than that of steel.

- Q: What are the different steel coil finishes available?

- There are several different steel coil finishes available, including hot rolled, cold rolled, galvanized, and stainless steel finishes.

- Q: How can the quality of steel coils be ensured?

- The quality of steel coils can be ensured through a combination of careful selection of raw materials, closely monitored manufacturing processes, and rigorous quality control measures. This includes conducting regular inspections and tests at various stages of production to ensure that the steel coils meet the required specifications and standards. Additionally, implementing proper storage and handling procedures, as well as adhering to industry best practices, can help maintain the quality of steel coils throughout their lifecycle.

- Q: What are the common coil transportation options?

- The common coil transportation options include trucking, rail transport, and sea freight.

- Q: What are the common uses of pre-painted steel coils?

- Pre-painted steel coils are commonly used in various industries such as construction, automotive, and appliances. They are utilized for manufacturing roofing and wall panels, garage doors, ductwork, and other building components. In the automotive sector, pre-painted steel coils are employed to produce body panels, trims, and other exterior parts. Additionally, they find applications in the manufacturing of household appliances like refrigerators, washing machines, and ovens.

- Q: If steel can rust with saltwater... then why are ships made of steel? can't we just use other metals like aluminium etc?

- Steel became the medium of construction almost be accident. The Royal Navy began to coat its wooden ships with a coating of steel to give them added protection in battle. They were known as the Iron Clads. From this it was a small step by such people as Brunnel to start construction in iron, then various other steels. The Great Eastern is a classic example. Over the last one hundred years the main improvement is in welding rather than a riveted construction. Improvements in steel have lead to a reduction in the scantlings and through this a reduction I the weight of the ship which has allowed for an increase in the carrying capacity. There always have been specialist ships built with alternative materials. Aluminium, wood, concrete and GRP. GRP. Also it must be remembered that there has been great advances in steel, from the early days of cast iron.

- Q: Is there any way to melt steel without the intense heat of a blast furnace?

- This Site Might Help You. RE: How do you melt steel without a blast furnace? Is there any way to melt steel without the intense heat of a blast furnace?

Send your message to us

Hot Dipped Galvanized Steel Coil (DC53D+Z, St05Z, DC53D+ZF)

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords