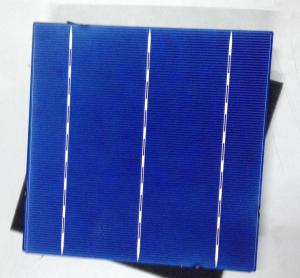

High Quality Supply Monocrystalline Drilling Solar Cells

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 1000000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Solar Cells:

solar cells, when struck by photons of light from the sun, generates an electrical current which can then be used to power DC or AC electrical loads.

A solar cell is made of silicon. Computer chips are made of this same material. Basically, when light strikes the surface of a solar cell some of it is absorbed into the silicon. This light energy bumps the electrons loose and causes energy to flow

Solar cells is made by solar wafer, it has three categories of solar cell right now, monocrystalline polycrystalline and thin film,These cells are entirely based around the concept of PN junction, which is the critical part of solar module, it is the part that can convert the light energy into electricity, the thickness is from 180um to 200um, with even busbars to conduct electricity, textured cell can decrease diffuse reflection; they are often electrically connected and encapsulated as a module. Photovoltaic modules often have a sheet of glass on the front (sun up) side, allowing light to pass while protecting semiconductor wafers from abrasion and impact due to wind-driven debris, rain, hail, etc. Solar cells are also usually connected in series in modules, creating an additive voltage. Connecting cells in parallel will yield a higher current;With high quality and stable quality. Our Cells can greatly improve the performance of Solar Modules.

Features:

High efficiencies up to 16.4%

Proven long term mechanical stability of silicone

Make of highly purified poly silicone

Three bus bars for reduced series resistance and improved module and cell efficiency

Blue anti-reflecting coating ensures improved light absorption and increased efficiency

Acid texturization offers a uniform appearance and virtually invisible crystal structure

Excellent low light behavior for improved energy yield

Specifications

Efficiency code | Efficiency(%) | Pmax(w) | Impp(A) | Vmpp(V) | Isc(A) | Voc(C) |

196 | ≥19.6 | 4.68 | 8.56 | 0.547 | 8.99 | 0.643 |

194 | 19.4-19.6 | 4.64 | 8.51 | 0.545 | 8.96 | 0.641 |

192 | 19.2-19.4 | 4.59 | 8.46 | 0.542 | 8.93 | 0.639 |

190 | 19.0-19.2 | 4.54 | 8.42 | 0.539 | 8.90 | 0.637 |

188 | 18.8-19.0 | 4.49 | 8.35 | 0.538 | 8.86 | 0.635 |

186 | 18.6-18.80 | 4.44 | 8.33 | 0.533 | 8.84 | 0.631 |

Solar Cells Advantage:

1. High efficiency and High power.

2. Long-term electrical stability.

3. Lowest price and Fastest delivery.

4. Good quality and good service.

5.Bulk supply

6. Good Warranty

7.Big Sale

FAQ

We have organized several common questions for our clients,may help you sincerely:

1, What’s price per product ?

A: It’s depends on the quantity, delivery date and payment terms of the order. We can talk further about the detail price issue. Our products is high quality with lower price level.

2, How to make payment?

We accept T/T or L/C.

3, What is your lead time?

Generally 1-5 weeks depends on the order quantity and your specific requirements.

4, Can you do OEM for us?

Yes, we can.

5, How do you pack your products?

We have rich experience on how to pack the panels to make sure the safety on shipment when it arrives at the destination.

Applications of solar cell

A solar cell is an electrical device that converts the energy of light directly into electricity by the photovoltaic effect, which is a physical and chemical phenomenon.[2] It is a form of photoelectric cell, defined as a device whose electrical characteristics, such as current, voltage, or resistance, vary when exposed to light. Solar cells are the building blocks of photovoltaic modules, otherwise known as solar panels.

Solar pv Modules: the application of solar cell

A PV module consists of many PV cells wired in parallel to increase current and in series to produce a higher voltage. 36 cell modules are the industry standard for large power production.

The module is encapsulated with tempered glass (or some other transparent material) on the front surface, and with a protective and waterproof material on the back surface. The edges are sealed for weatherproofing, and there is often an aluminum frame holding everything together in a mountable unit. In the back of the module there is a junction box, or wire leads, providing electrical connections.

There are currently four commercial production technologies for PV Modules:

Single Crystalline

This is the oldest and more expensive production technique, but it's also the most efficient sunlight conversion technology available. Module efficiency averages about 10% to 12%*

Polycrystalline or Multicrystalline

This has a slightly lower conversion efficiency compared to single crystalline but manufacturing costs are also lower. Module efficiency averages about 10% to 11%*

String Ribbon

This is a refinement of polycrystalline production, there is less work in production so costs are even lower. Module efficiency averages 7% to 8%*

Amorphous or Thin Film

Silicon material is vaporized and deposited on glass or stainless steel. The cost is lower than any other method. Module efficiency averages 5% to 7%*

Solar Panels: the application of solar cells

Solar Photovoltaic panels constitute the solar array of a photovoltaic system that generates and supplies solar electricity in commercial and residential applications. Each module is rated by its DC output power under standard test conditions, and typically ranges from 100 to 365 watts. The efficiency of a module determines the area of a module given the same rated output – an 8% efficient 230 watt module will have twice the area of a 16% efficient 230 watt module. There are a few solar panels available that are exceeding 19% efficiency. A single solar module can produce only a limited amount of power; most installations contain multiple modules. A photovoltaic system typically includes a panel or an array of solar modules, a solar inverter, and sometimes a battery and/or solar tracker and interconnection wiring.

- Q: How do solar cells perform in regions with high levels of salt spray and corrosive environments?

- Solar cells can be affected by salt spray and corrosive environments, which can degrade their performance over time. The exposure to high levels of salt spray can lead to corrosion of the cell's components, such as the metallic contacts, leading to a decrease in efficiency. However, manufacturers have developed various protective coatings and materials to mitigate the effects of salt spray and corrosion, ensuring the long-term performance of solar cells in such challenging environments.

- Q: What are the maintenance requirements for solar cells?

- The maintenance requirements for solar cells are minimal. They generally require regular cleaning to remove dust or debris that may accumulate on the surface, and occasional inspection to ensure proper functioning and detect any signs of damage or wear. Additionally, it is recommended to check the connections and wiring periodically to ensure they are secure. Overall, solar cells are known for their durability and low maintenance needs.

- Q: The advantages and effects of solar energy

- There are transportation problems, especially in the underdeveloped rural areas, islands and remote areas more valuable value.Third: solar energy is a clean energy in the development and utilization, will not produce waste, waste water, waste gas, no noise

- Q: Can solar cells be used in electric fences?

- Yes, solar cells can be used in electric fences. Solar cells can convert sunlight into electricity, which can power the electric fence energizer. This eliminates the need for a constant power supply or batteries, making it a sustainable and cost-effective option for powering electric fences.

- Q: How long does it take to make a solar cell?

- 1-2 days.

- Q: My solar cells are broken, can I just buy one and replace it?

- Of course you can.

- Q: What is the average lifespan of a solar cell in space?

- The average lifespan of a solar cell in space can vary depending on several factors such as the quality of the materials used, the level of radiation exposure, and the specific mission requirements. However, on average, solar cells in space can last anywhere from 10 to 25 years.

- Q: How do monocrystalline solar cells differ from polycrystalline solar cells?

- Monocrystalline solar cells are made from a single crystal structure, typically silicon, which allows for higher efficiency and performance in converting sunlight into electricity. On the other hand, polycrystalline solar cells are made from multiple crystal structures, resulting in a lower efficiency but a more cost-effective option.

- Q: What is the expected degradation rate of a solar cell?

- The expected degradation rate of a solar cell can vary depending on various factors such as the quality of materials used, manufacturing processes, environmental conditions, and maintenance practices. However, on average, a well-designed and properly maintained solar cell can experience an annual degradation rate of around 0.5% to 1%. This means that over time, the solar cell's efficiency may decrease by 0.5% to 1% per year.

- Q: How is the efficiency of a solar cell calculated?

- The efficiency of a solar cell is calculated by dividing the maximum power output of the solar cell by the total amount of solar energy it receives.

Send your message to us

High Quality Supply Monocrystalline Drilling Solar Cells

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 1000000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords