High Quality Pile

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

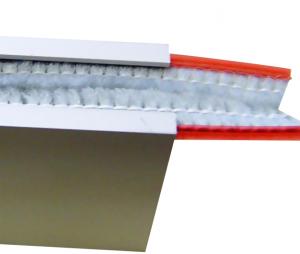

We mainly engaged in manufacturing PHC concrete piles with diameters of Φ600~Φ1400 for wharf. Every year, the company produces various types of concrete piles of over 150,000 meters with single-section pile of 41meter long and annual gross output value up to RMB 600 million.

With years’ manufacturing experience of concrete piles and a great number of excellent technological and management talents, the company persists in technical innovation and research of new products. The large-diameter PHC concrete piles with merits such as good bending strength, large bearing capacity, fine resistance against the external force and so forth have been the preferential choice of structural materials for foundation engineering construction such as large ports, wharfs, shipyard, huge bridges, high-rise buildings, heavy factories, high-speed railway, etc.

The company holds the operation philosophy of “honest, practical and harmonious for win-win” and persists in the quality guideline of “constant improvement with prohibition of non-conforming products into construction site” to provide you sincerely with superior products and service.

- Q: What are the different shapes and sections of steel profiles?

- There are various shapes and sections of steel profiles, including beams, channels, angles, tubes, and plates. Beams are commonly used for structural support and come in I, H, and T shapes. Channels have a C-shaped cross-section and are often used for framing and support. Angles have an L-shaped cross-section and are utilized for bracing and corner reinforcement. Tubes are hollow cylindrical shapes used for various applications, such as pipes and structural components. Plates are flat, rectangular pieces of steel used for structural purposes and as a base for other components.

- Q: What are the common width tolerance limits for stainless steel flats?

- The common width tolerance limits for stainless steel flats typically range from +/- 0.005 to +/- 0.030 inches, depending on the specific grade and thickness of the material.

- Q: What are the main factors influencing the choice of steel wire rod price?

- The choice of steel wire rod price is influenced by several key factors. Firstly, the cost of raw materials, including iron ore and scrap metal, has a significant impact on the price. Fluctuations in the price of these inputs due to supply and demand dynamics, global economic conditions, and government policies can directly affect the overall price of steel wire rods. Secondly, production and manufacturing costs, such as labor, energy, and equipment costs, play a crucial role in determining the price. Technological advancements, efficiency improvements, and economies of scale can influence production costs and ultimately impact the price of steel wire rods. Thirdly, market demand and supply dynamics greatly impact the price. Factors such as construction and infrastructure projects, automotive industry demand, and overall economic conditions can influence the demand for steel wire rods. Similarly, changes in production capacity, import/export regulations, and market competition affect the supply side of the market, leading to price fluctuations. Furthermore, international trade policies and tariffs imposed by governments can have a significant impact on the price. Trade disputes, anti-dumping measures, and import/export restrictions can disrupt the supply chain and create price volatility in the market. Fluctuations in currency exchange rates can also affect the price of steel wire rods, especially in international trade. Exchange rate movements between the currency of the producer and the buyer's currency can influence the final price paid for the product. In addition, market speculation and investor sentiment can influence the price. Market expectations, perceptions of future demand, and investor sentiment towards the steel industry can lead to price fluctuations. It is important to note that these factors are interconnected and can interact in complex ways. Additionally, other factors such as environmental regulations, technological advancements, and geopolitical events can also indirectly impact the price of steel wire rods.

- Q: Are steel angles resistant to pests and termites?

- Steel angles have a high resistance to pests and termites, unlike wood, which can be damaged by these insects and other pests. Steel is an inorganic material that does not provide a food source for pests, making it an excellent option for construction projects in areas that are prone to infestations. Furthermore, steel does not rot or decay, further increasing its resilience against pests. Consequently, incorporating steel angles in construction can safeguard buildings against potential damages inflicted by pests and termites.

- Q: How do steel round bars compare to glass round bars?

- Steel round bars and glass round bars differ in terms of their properties and applications. Here's a comparison: Strength and Durability: Steel round bars possess exceptional strength and durability, with a high tensile strength that allows them to withstand heavy loads and pressure without deformation. Conversely, glass round bars are fragile and easily break under stress or impact, making them unsuitable for structural applications where strength is crucial. Weight: Steel round bars are considerably heavier than glass round bars. Although this can be advantageous in applications requiring stability and support, it can be a disadvantage in situations where lightweight materials are desired. Corrosion Resistance: Steel round bars are susceptible to corrosion when exposed to moisture or harsh environments. However, they can be safeguarded by coatings or alloys that enhance their resistance to corrosion. In contrast, glass round bars are not prone to corrosion, making them an ideal choice in corrosive environments. Transparency and Aesthetics: Glass round bars have the advantage of transparency, making them suitable for decorative purposes or applications where visibility is important. On the other hand, steel round bars are opaque and lack this characteristic. Thermal Conductivity: Steel round bars have higher thermal conductivity compared to glass round bars. This property makes them more suitable for applications requiring heat transfer or dissipation. Cost: Steel round bars are generally more affordable than glass round bars. The production processes and limited availability of specialized glass types contribute to the higher cost of glass round bars. In conclusion, steel round bars are favored for their strength, durability, and cost-effectiveness, making them suitable for structural applications. Conversely, glass round bars offer transparency, aesthetic appeal, and corrosion resistance, making them suitable for decorative or specific applications where visibility is important. Ultimately, the choice between the two materials depends on the specific requirements and constraints of the project at hand.

- Q: What are the factors that affect the wear resistance of steel strips?

- There are several factors that can affect the wear resistance of steel strips. Firstly, the type and composition of the steel used in the strips play a significant role. Different alloys and heat treatments can be employed to enhance the wear resistance of steel. For instance, adding elements such as chromium, manganese, and tungsten can significantly improve the hardness and wear resistance of the steel strips. Secondly, the microstructure of the steel also affects its wear resistance. Steel strips with a fine and uniform grain structure tend to have better wear resistance compared to those with larger grains. This is because a fine grain structure provides more barriers to dislocations and helps to distribute the applied load more evenly, reducing wear. The hardness of the steel strips is another crucial factor. A higher hardness generally results in better wear resistance. Hardness can be achieved through various means, such as heat treatment processes like quenching and tempering or through the addition of alloying elements. The surface finish of the steel strips is also important. Smooth and polished surfaces tend to exhibit better wear resistance compared to rough or uneven surfaces. A smooth surface reduces friction and minimizes the chances of abrasive wear. Furthermore, the environmental conditions in which the steel strips operate can affect their wear resistance. Factors like temperature, humidity, and the presence of corrosive substances can accelerate wear. It is essential to consider these conditions when selecting the appropriate type of steel and applying protective coatings if necessary. Lastly, the load and speed at which the steel strips are subjected to also influence wear resistance. Higher loads and higher speeds generally result in increased wear. Therefore, it is crucial to consider the specific application requirements and select the steel strips that can withstand the expected loads and speeds to ensure optimal wear resistance.

- Q: How do you prevent discoloration or staining on stainless steel sheets?

- To prevent discoloration or staining on stainless steel sheets, there are several steps you can take: 1. Regular Cleaning: Clean the stainless steel sheets regularly using mild soap or detergent and warm water. Avoid using abrasive cleaners or scrub brushes that can scratch the surface. After cleaning, rinse thoroughly with clean water and dry with a soft cloth to prevent water spots. 2. Avoid Harsh Chemicals: Avoid using harsh chemicals such as bleach, ammonia, or chlorine-based cleaners on stainless steel sheets. These chemicals can cause discoloration or staining. Instead, opt for stainless steel-specific cleaners or natural cleaners like vinegar or lemon juice. 3. Proper Storage: Store stainless steel sheets in a clean and dry environment to avoid exposure to moisture or humidity. Moisture can lead to corrosion or rust, which can cause discoloration. If the sheets are stored outdoors, cover them properly to protect them from rain or snow. 4. Use Protective Coatings: Applying a protective coating or sealant on stainless steel sheets can help prevent discoloration or staining. There are various products available in the market specifically designed for stainless steel protection. Follow the manufacturer's instructions for application and reapplication, if necessary. 5. Avoid Contact with Reactive Metals: Avoid contact between stainless steel sheets and other reactive metals such as iron, copper, or aluminum. When these metals come into contact with stainless steel, a chemical reaction called galvanic corrosion can occur, leading to discoloration and staining. Ensure separation or isolation between stainless steel and reactive metals. 6. Regular Maintenance: Regularly inspect the stainless steel sheets for any signs of discoloration, staining, or damage. Address any issues promptly to prevent further deterioration. If you notice any stubborn stains, use a non-abrasive stainless steel cleaner and a soft cloth to gently rub the affected area in the direction of the grain. By following these preventive measures, you can maintain the appearance and integrity of stainless steel sheets, ensuring they remain free from discoloration or staining for an extended period.

- Q: What are the different types of packaging available for stainless steel flats?

- There are several different types of packaging available for stainless steel flats, depending on the specific requirements and preferences of the customers. 1. Wooden Crates: This is one of the most common and traditional packaging options for stainless steel flats. The flats are carefully stacked and secured within a sturdy wooden crate to protect them from any potential damage during transportation. 2. Cardboard Boxes: Another commonly used packaging option is cardboard boxes. Stainless steel flats are placed in these boxes and then sealed with tape to ensure safe transportation. Cardboard boxes are lightweight, cost-effective, and easy to dispose of after use. 3. Plastic Wrapping: Some stainless steel flats may be packaged using plastic wrapping. This involves tightly wrapping the flats in a layer of plastic film to provide protection against moisture, dust, and scratches. Plastic wrapping is commonly used when the flats are being shipped in bulk. 4. Pallets: For larger quantities of stainless steel flats, packaging them on pallets is a popular option. The flats are stacked on a pallet, secured with straps or stretch wrap, and then transported using forklifts or pallet jacks. Pallet packaging is efficient for handling and storage purposes. 5. Tubes or Pipes: In the case of longer stainless steel flats, packaging them in tubes or pipes is often preferred. The flats are rolled and inserted into cylindrical tubes or pipes, which provide enhanced protection against bending or damage during shipment. 6. Customized Packaging: Depending on the specific needs of the customer, customized packaging solutions can be developed. This may include using foam inserts, corner protectors, or additional layers of protective materials to ensure the stainless steel flats reach their destination in optimum condition. It is important to note that the choice of packaging for stainless steel flats may vary depending on factors such as the size, weight, quantity, transportation method, and destination. The packaging should be chosen to provide adequate protection against potential damage, while also considering cost-effectiveness and ease of handling.

- Q: What are the considerations for the design of steel structures in areas with high humidity?

- When designing steel structures in areas with high humidity, several considerations need to be taken into account. Firstly, the choice of steel material is crucial as it should possess excellent corrosion resistance properties. Stainless steel or weathering steel are often preferred in such environments. Additionally, protective coatings or paints should be applied to the steel to provide an extra layer of defense against moisture and humidity. Regular inspections and maintenance are also necessary to identify any signs of corrosion or damage and address them promptly. Moreover, proper ventilation and drainage systems should be incorporated into the design to minimize the accumulation of moisture and prevent the formation of condensation within the structure. This helps to mitigate the risk of corrosion and deterioration over time. Lastly, the design should consider the effects of high humidity on the overall structural integrity. Adequate measures should be taken to account for potential expansion and contraction of the steel due to changes in temperature and humidity, ensuring the long-term stability and safety of the structure. Considering these factors will contribute to the durability, longevity, and safety of steel structures in areas with high humidity.

- Q: Do steel channels have any specific thermal expansion properties?

- Yes, steel channels do have specific thermal expansion properties. Like all materials, steel expands and contracts with changes in temperature. The thermal expansion of steel channels is primarily determined by the coefficient of linear expansion, which is a measure of how much the material expands per unit length per degree Celsius (or per unit length per degree Fahrenheit). The coefficient of linear expansion for steel typically ranges between 10 to 13 parts per million per degree Celsius (10-13 ppm/°C). This means that for every degree Celsius increase in temperature, a steel channel will expand by approximately 10 to 13 parts in a million of its original length. It is important to consider the thermal expansion of steel channels in various applications to ensure proper design and functionality. For example, in structures where steel channels are used, such as bridges or buildings, allowance must be made for the expansion and contraction of the channels to prevent stress buildup and potential damage. Expansion joints or other methods of accommodating thermal expansion are typically incorporated into the design to account for these properties. In summary, steel channels do exhibit specific thermal expansion properties, which are determined by the coefficient of linear expansion. Understanding and accounting for these properties is crucial in the design and application of steel channels to ensure their structural integrity and functionality in varying temperature conditions.

Send your message to us

High Quality Pile

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords