High Quality A1 Type PP-R Ball Valve with Brass Ball - Plastic Water Pipe Compression Fittings

- Loading Port:

- Ningbo

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

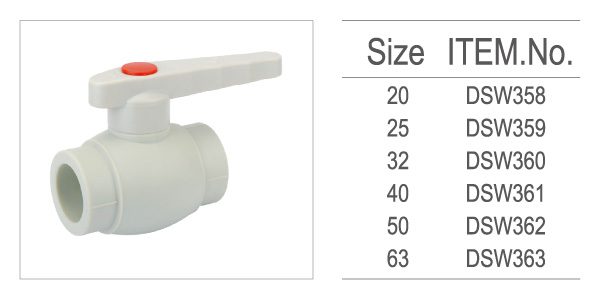

PP-R ball valve with brass ball size:20-40

1.Material:Random Polypropylene(Hyosung R200P);

2.ISO9001&ISO14001;

3.Standard:GB/T 18742.3-2002, DIN8077/8078;

4.OEM also ok

1) Healthy, bacteriological neutral, conforming to drinking water standards

2) Resistant to high temperatures, good impact strength

3) Convenient and reliable installation, low construction expenses

4) Excellent heat-insulation property from minimum thermal conductivity

5) Lightweight, convenient to transport and handle, good for labor-saving

6) Smooth inner walls reduce pressure loss and increase flow speed

7) Sound insulation (reduced by 40% compared to galvanized steel pipes)

8) Light colors and excellent design ensure suitability for both exposed and hidden installation

9) Recyclable, environment-friendly, accords with GBM standards

- Q: Are plastic pipe fittings compatible with compression couplings?

- Yes, plastic pipe fittings are compatible with compression couplings.

- Q: Are plastic pipe fittings compatible with solvent welding?

- Yes, plastic pipe fittings are compatible with solvent welding. Solvent welding is a process of joining plastic pipes and fittings by using a solvent adhesive. The solvent softens the plastic, allowing the pipe and fitting to fuse together, creating a strong and leak-proof connection.

- Q: Can plastic pipe fittings be used in fire-resistant systems?

- No, plastic pipe fittings cannot be used in fire-resistant systems as they have a low resistance to heat and can melt or release toxic fumes during a fire.

- Q: Are plastic pipe fittings suitable for use in breweries and distilleries?

- Yes, plastic pipe fittings are suitable for use in breweries and distilleries. They are lightweight, resistant to corrosion, and have low levels of chemical leaching, making them an ideal choice for transporting water, ingredients, and other liquids in these industries. Additionally, plastic pipe fittings are easy to install, maintain, and clean, making them a cost-effective and efficient solution for breweries and distilleries.

- Q: Are plastic pipe fittings resistant to rodents and insects?

- Yes, plastic pipe fittings are generally resistant to rodents and insects. Unlike materials like wood, plastic does not attract pests as it does not provide a food source or nesting material. Additionally, plastic fittings are typically designed to have a tight and secure fit, making it difficult for rodents or insects to access the pipe system.

- Q: Are plastic pipe fittings resistant to oil and grease?

- Yes, plastic pipe fittings are generally resistant to oil and grease.

- Q: Are plastic pipe fittings resistant to fungal and bacterial growth?

- Yes, plastic pipe fittings are generally resistant to fungal and bacterial growth due to their non-porous nature, which makes it difficult for microorganisms to adhere and grow on the surface.

- Q: Are plastic pipe fittings resistant to mechanical stress?

- Yes, plastic pipe fittings are generally resistant to mechanical stress. They are designed to withstand the pressure and forces associated with the transportation of fluids or gases. However, the level of resistance may vary depending on the type and quality of the plastic used in the fittings, as well as the specific application and conditions in which they are used.

- Q: Can plastic pipe fittings be used for water supply in remote areas?

- Yes, plastic pipe fittings can be used for water supply in remote areas. They are lightweight, durable, and resistant to corrosion, making them suitable for long-distance transportation. Additionally, plastic fittings are easy to install and maintain, which is beneficial in remote locations where resources may be limited.

- Q: Can plastic pipe fittings be used for sewer systems?

- Yes, plastic pipe fittings can be used for sewer systems. Plastic materials such as PVC (polyvinyl chloride) and ABS (acrylonitrile butadiene styrene) are commonly used in sewer systems due to their durability, corrosion resistance, and affordability. Plastic pipe fittings are designed to connect and secure plastic pipes, offering a reliable and long-lasting solution for sewage transportation.

Send your message to us

High Quality A1 Type PP-R Ball Valve with Brass Ball - Plastic Water Pipe Compression Fittings

- Loading Port:

- Ningbo

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords