High Pressure Rubber Fuel Hose High Temperature Steel Layer

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m

- Supply Capability:

- 50000 m/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

Place of Origin: | Hebei, China (Mainland) | Brand Name: | CMAX | Model Number: | R13 |

Name: | R13 rubber & Hydraulic Hose | Material: | rubber & steel wire | Inner tube: | Nitrile |

Cover: | Black neoprene blend | Reinforcement: | four , six spiralled of high-tensile steel wire | Color: | Black/Red/Green/Yellow |

Temperature range: | -40°Fto 212°F(-40°C-100°C) | Applicable standards: | GB/T 10544 R13, EN 856 R13, SAE J517 R13 | Application: | Used for petroleum and Watrer-based hydraulic fluids |

Factory or not: | Factory |

Packaging & Delivery

Packaging Details: | Spiral hose Plastic packing or according to the customer's requirement |

Delivery Detail: | usually 5-30 days. |

High Pressure/coal/oil Hydraulic Hose

Product Description

Structure

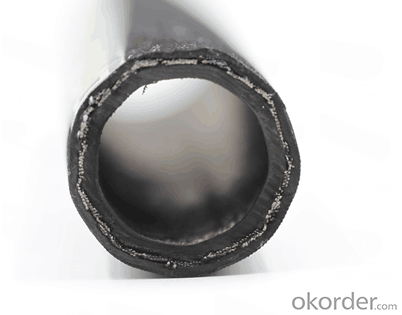

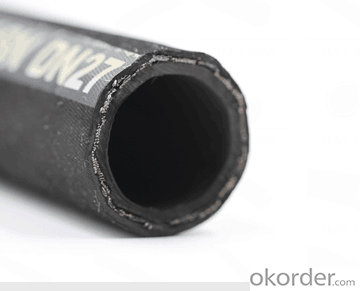

The hydraulic hose consists of an inner tube of liquid resistant synthetic rubber, middle rubber layer, four layers spiral wire reinforcement, and superior weather resistant synthetic rubber cover.

1. Inner Tube: Neoprene

2. Reinforcement: four or six alternating layeers of spiral high tensile steel wire

3. Cover: Black neoprene blend that meets MT98 and GB/T 15907 Flame resistance

4. Application Standards: GB/T 10544 R13, EN 856 R13, MT98 R13.

Application

hydraulic hose is a medium pressure hose that can be used in mobile, machine tool, agricultural application and other hydraulic systems.

It can also be used in conveying petroleum or water based hydraulic fluids which under specific pressure and temperature.

Working Temperature : Oil: -40°C to +100°C, Air: -30°C to 50°C, Water Emulsion under +80°C

Features

1. It provides superior oil resistance, heat resistance and aging resistance by using special synthetic rubber.

2. It provides high pressure resistance and superior impulse resistance.

3. It provides superior bonding in hose internal, soft use and small deformation under pressure.

4. It provides superior kink resistance and fatigue resistance and longer services life.

FAQ

Q1. Do you produce smooth or cloth wrapped cover?

1. A. Both, we can produce both cover, which depends on customer’s request.

Q2. Do you produce embossed marking?

1. A. Yes, we do provide embossed and printing markings with different color.

Q3. Can you produce product with my own brand?

1. A. Yes, we have been offering OEM services for 20 years.

Q4. Does your product have different color hose?

1. A. Yes, we currently provide black, grey, red, blue and yellow.

Q5. How long does my order take to be delivered?

1. A. It usually takes 5 to 30 days, which generally depends on the quantity of your order and our storage.

- Q: Acid burette and burette why different structure

- Acid burette can be used frosted glass cock, convenient use, good sealing performance.

- Q: Why does Br2 corrode rubber tubes?

- Bromine elements need to be sealed with water to prevent steam escaping and harm the human body. Oxidizing, there are a variety of variable valency, under normal temperature and weak water reaction, generating hydrobromic acid and bromate. Heating increases the speed of reaction. Hydrobromide is a strong acid with an acid stronger than that of hydrogen chloride. Bromine is commonly used in organic synthesis.

- Q: What is the essential difference between silicone tube and rubber tube?

- The main performance of the rubber tube: rubber tube is non-toxic, environmental protection, physical inertia, UV resistance, ozone resistance, resistance to high temperature (-8 to 300), high transparency, strong resilience, resistant to compression permanent deformation, oil resistance, impact resistance, acid and alkali resistance, wear resistance, flame resistance, voltage, conductive properties.Scope of application: supporting electrical appliances, electronics, furniture, equipment, toys, hardware, medical equipment, sporting goods, audio, lighting, machinery, automobile and other industries.

- Q: The rubber is sheathed on a metal cylinder. How should they be connected?

- If you describe it, it is recommended that a soft binder such as 704 silicone gel will be used to prevent shock absorption and separation. Metal surface to rust treatment, clean can be coated adhesive, rubber cover surface is best polished, degreasing treatment effect is good!

- Q: What is the difference between plastic lined steel pipe and rubber lined steel pipe?

- Difference1. processing technology:Rubber lined steel pipe generally adopts the manual adhesive, vulcanizing process (can also be cold bonding operation); plastic lining pipe generally adopts the heating equipment, the overall rotational (tight loose lining, lining, molding, molding) main process steps can be completed by means of equipment. Therefore, the production efficiency of the lining pipe is obviously higher than that of the lining rubber tube.2.: the physical properties of rubber lined pipe due to the inheritance of the excellent properties of rubber, the chemical corrosion and wear resistance, heat resistance is also very prominent, and the plastic lined pipe in addition to resistance to chemical corrosion and lining hose close to the outside, in the wear resistance, heat resistance and adhesive strength are not as lining hose.

- Q: Which is better for binding files with rubber tubes and cotton threads?

- X rubber hose and rubber band type light aging fast, not suitable for long-term preservation, cotton is afraid of water and insects

- Q: How do you remove the burrs on the rubber joint quickly?

- The thickness of the rubber joint burr than the thickness of the product is much thinner, so brittle speed than the speed burr brittle products quickly, in burr brittle and brittle products without this period of time can be hit by projectile projectile with frozen products deburring machine, thereby removing burrs in embrittlement.

- Q: Hydraulic hose joint configuration

- The utility model relates to an ultrahigh pressure drilling hose joint: an ultrahigh pressure drilling hose joint used on an oil field mining device, which comprises a sleeve and a connecting section which is connected with the core rod ring sleeve. The inner hole of the sleeve and the outer round surface of the core rod of the connecting section are correspondingly matched in turn, and the utility model is connected with an anti pulling out section, a sealing section and a transition section. Both the stripping section and the sealing section are respectively provided with a plurality of annular grooves on the excircle surface of the inner hole of the sleeve and the core rod, and are matched with or matched with the bulge. The test shows that when the working pressure of the inner cavity of the hose is 70MPa, the pulling resistance and the tightness of the hose joint can still be effectively guaranteed. The joint of the hose is welded because of the high temperature generated by the welding, and the locking of the sealing adhesive layer of the inner cavity of the rubber tube is effectively prevented from tearing by the locking of the transition section. Compared with the prior art, the production failure of the hose joint is eliminated, and the service cost is obviously reduced.

- Q: Stainless steel metal hose and flexible rubber joint which is easy to use?

- The pressure and temperature bearing capacity of the stainless steel metal hose shall be due to the rubber joint, and the length of the product can be customized according to the requirements of the field, and the form of the joint is very rich.

- Q: Do you need a hose connection to connect the ventilation pipe to the exhaust fan? Under what circumstances? Under what circumstances?

- The exhaust fan running noise and vibration is relatively large, the wind pipe made of sheet iron, the thin wall affected by the fan vibration will produce two times the noise, so the general air pipe to both sides of fan and soft joints, if no one in the floor or the condition of small diameter pipeline can not be added.

Send your message to us

High Pressure Rubber Fuel Hose High Temperature Steel Layer

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m

- Supply Capability:

- 50000 m/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords