High Pressure Rubber Fuel Hose High Temperature One Steel Layer

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m

- Supply Capability:

- 50000 m/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

Place of Origin: | Hebei, China (Mainland) | Brand Name: | CMAX | Model Number: | R13 |

Name: | R13 rubber & Hydraulic Hose | Material: | rubber & steel wire | Inner tube: | Nitrile |

Cover: | Black neoprene blend | Reinforcement: | four , six spiralled of high-tensile steel wire | Color: | Black/Red/Green/Yellow |

Temperature range: | -40°Fto 212°F(-40°C-100°C) | Applicable standards: | GB/T 10544 R13, EN 856 R13, SAE J517 R13 | Application: | Used for petroleum and Watrer-based hydraulic fluids |

Factory or not: | Factory |

Packaging & Delivery

Packaging Details: | Spiral hose Plastic packing or according to the customer's requirement |

Delivery Detail: | usually 5-30 days. |

High Pressure/coal/oil Hydraulic Hose

Product Description

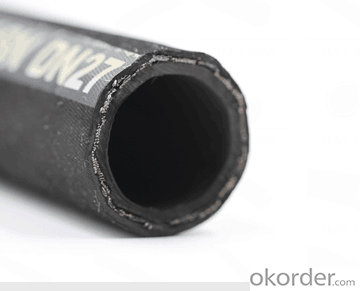

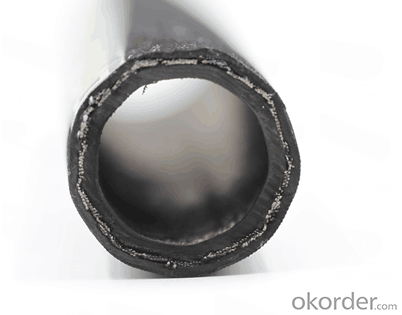

Structure

The hydraulic hose consists of an inner tube of liquid resistant synthetic rubber, middle rubber layer, four layers spiral wire reinforcement, and superior weather resistant synthetic rubber cover.

1. Inner Tube: Neoprene

2. Reinforcement: four or six alternating layeers of spiral high tensile steel wire

3. Cover: Black neoprene blend that meets MT98 and GB/T 15907 Flame resistance

4. Application Standards: GB/T 10544 R13, EN 856 R13, MT98 R13.

Application

hydraulic hose is a medium pressure hose that can be used in mobile, machine tool, agricultural application and other hydraulic systems.

It can also be used in conveying petroleum or water based hydraulic fluids which under specific pressure and temperature.

Working Temperature : Oil: -40°C to +100°C, Air: -30°C to 50°C, Water Emulsion under +80°C

Features

1. It provides superior oil resistance, heat resistance and aging resistance by using special synthetic rubber.

2. It provides high pressure resistance and superior impulse resistance.

3. It provides superior bonding in hose internal, soft use and small deformation under pressure.

4. It provides superior kink resistance and fatigue resistance and longer services life.

FAQ

Q1. Do you produce smooth or cloth wrapped cover?

1. A. Both, we can produce both cover, which depends on customer’s request.

Q2. Do you produce embossed marking?

1. A. Yes, we do provide embossed and printing markings with different color.

Q3. Can you produce product with my own brand?

1. A. Yes, we have been offering OEM services for 20 years.

Q4. Does your product have different color hose?

1. A. Yes, we currently provide black, grey, red, blue and yellow.

Q5. How long does my order take to be delivered?

1. A. It usually takes 5 to 30 days, which generally depends on the quantity of your order and our storage.

- Q: What glue can glue rubber tube?

- Location: in the face and then drop a little sticky rubber JL-330 iron speedglue, immediately bonded, and keep to the hardening, hardening time ranging from a few seconds. About 30 minutes to reach practical strength, 24 hours after the maximum intensity.

- Q: Why should the high pressure hydraulic tube peel off the outer skin?

- There are two reasons for stripping. One is that the inner diameter of the sleeve is the standard series, and that the outer diameter of the hose is not suitable, so it must be peeled. Two, after stripping, the sleeve can be directly pressed on the steel wire layer. The connection is reliable, and it is not easy to pull out.Whether or not to peel the rubber depends on the fit between the hose and the sleeve. Not every rubber hose is to be stripped.

- Q: Classification of metal hoses

- Corrugated metal hose from the structure point of view, metal bellows with two pieces of tape and pipe, they can be molded out of ring bellows and spiral bellows. Just because the corrugated pipe buckle strip forming there is always a certain length of brazing or welding and joints, these places often have accumulated working medium residue, and precipitated a mechanical impurities pollution cavity cleaning test and working medium. As a result, its trustworthiness is relatively poor. Bellows ring is the number of rings and several concave diaphragm outer concentric semi circle tangent, and several inner concave semicircular ring connected with the vest tangent to the special geometry of the pipe. Its billet is mainly made of tubes, and this kind of bellows has the characteristics of large flexibility, good elasticity, simple manufacture and small rigidity. Suitable for making general pressure, flexible requirements of high, medium diameter of the metal hose. Spiral corrugated pipe is a certain length of the spring winding shaped diaphragm spring shape around the outer edge and concave concentric semicircular ring tangent, and inner spring winding shaped concave semicircular ring connected with the vest tangent to the special geometry of the pipe. The corrugated tube has the characteristics of high strength, large rigidity and simple manufacture, and is suitable for making metal hose with high and medium pressure requirements, high and medium pressure, medium and small diameter.

- Q: Will the outside of the brake hose of the car burst apart?

- There is a potential safety hazard to the outside rubber skin. It is possible to slam on the brake. The brakes are not trivial, so I suggest you replace them in time.

- Q: How to remove the smell of gasoline in the car?

- The local gasoline smell is introduced into the car from outside environment.Answer: turn on the air conditioner, use the internal circulation mode, and open the sunroof exhaust.

- Q: Hose connector JB1885-77 what is the standard?

- GB A flat joint core series hose assembly standard.

- Q: The main features of Linatex rubber tube or what are the characteristics?

- Linard, BB:, halogenated butyl rubber. Acid and alkali resistance, good air tightness, high temperature resistance.Linaplus, FG:, natural rubber, FDA certified, for long-term exposure to food applications.Linaplus, OZ:95% natural rubber, excellent abrasion resistance, UV resistance, and ozone performance

- Q: The gas water heater uses metal pipes and rubber pipes

- Rubber tube will be aging for long time, it is better to use gas special stainless steel bellows

- Q: Single ball chloroprene rubber flexible joint, Shanghai Song Jiang rubber ball joint manufacturer where?

- A tubular rubber component is composed of inner and outer layers of rubber, cord and steel ring, which is vulcanized and molded and then combined with a metal flange or a parallel joint. This product can reduce vibration and noise, and can be compensated by thermal expansion and cold contraction due to temperature changes. It is widely used in various piping systems. If I can help you, please accept it.

- Q: What's the difference between a silicone tube and a rubber tube?

- Silicon hose performance: cold resistant, high temperature resistant. Harmless, non-toxic, tasteless;Suitable for small household appliances (coffee pot, kettle, electric iron, electric cooker, frying pan, disinfection cabinet, drinking machine, pulp machine, bread machine, gas cooker, water heater) and electronic, automobile, medical and other mechanical products.

Send your message to us

High Pressure Rubber Fuel Hose High Temperature One Steel Layer

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m

- Supply Capability:

- 50000 m/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords