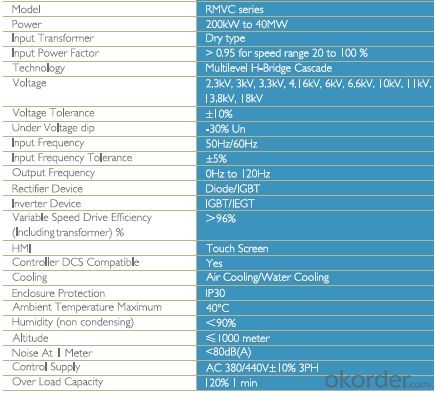

High Medium Voltage Drive 11KV 280KW RMVC4000-A110/360 VFD

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 100000 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Energy-saving Solutions for Enterprise

1、Program Overview

◆Saving energy achieves 10% -70%

◆The enterprises do not need to pay for expense of equipment manufacture and installation.

◆Enterprises only need to pay the saving electricity expense to our company according to the actual quantity of energy saving after the equipments put into operation.

◆According thousands of the projects’ implementation experiences, such projects recover the investments in three or four years. (Equipment service life is 15 years)。

◆Our company will no longer charge the saving electricity expense after recovering the investment.

The significance of the program:

1)、Concentrate on solving problems of energy conservation, make enterprises’ energy-saving work reach new level and take their social responsibility。

2) 、Avoid the enterprises reactive power fine of low power factor caused by electric energy using (according to Ministry of Electric Power and Water Resources, State Price Control Bureau establish the " measures of power factor adjustment expense ").

3)、Avoid the high-energy consumption enterprises are implemented differential prices because of the changes of national power regulation.

4)、For the standard-conforming large-scale (saved energy equal 10 thousand tons standard coal or more) energy-saving technological transformation projects, China will reward the enterprises for energy saving which based on the "Financial Incentives Interim Measure for Energy-saving Technological Transformations" established by Ministry of Finance, the National Development and Reform Commission.( Amount of 200 yuan / ton of standard coal).

5)、Equipments recovery period is generally 3-4 years, each period payment equal to the amount of current energy-saving benefits, and equipments service life are 15 years, so enterprises will gain huge energy-saving benefits.

2、Implementation Process

Energy Audit

Energy Saving Program Design

Construction Design

Equipments Manufacture

Construction and installation

Maintenance and Repair

Energy Monitoring and Efficiency Insurance

Recovery of Program Investment

3、Program Features

High energy-saving efficiency

The project saving rate is generally 10% -30%, highest is up to 70%.

Clients Zero Investment

All works of design, audit, manufacturing, construction, monitoring are handled by RXPE, clients does not require investment.

Energy-saving Guarantee

RXPE promises the amount of energy saving, ensuring that clients’ cost reduction immediately.

Short Investment Recovery Period

The investment recovery period is short, average period is 3-4 years.

Low Risk

Customers do not input large sums of money also can enjoy professional energy-saving products, technologies and services, and the investment risk is very low.

Improvement of Cash Flow

Customers with the support of RXPE approve energy-saving program to improve cash flow, invest the limited funds into other priority investment areas.

Enhance competitiveness through implementing energy conservation, improving energy-saving efficiency, reducing energy costs and enhancing the quality of environment, establish green corporate image and enhance market competiveness.

- Q: In the official website to buy ThinkPad notebook, to the power adapter?

- Hello, generally there will be a power adapter with Kazakhstan, unless there is a special note bare metal

- Q: Can the laptop's power adapter be used for years?

- Generally 3 to 5 years is not a problem, good quality can be used for 10 years. Power adapter is a small portable electronic equipment and electrical and electronic power supply conversion equipment, generally by the shell, power transformer and rectifier circuit, according to its output type can be divided into AC output and DC output type; by way of connection Divided into wall and desktop. Extensive support in the phone son machine, game consoles, language repeaters, Walkman, notebook computers, cellular phones and other equipment.

- Q: What is the application of variable frequency speed control?

- Generally used in the need for continuous speed control of the place. With the general exchange of motor than its advantages is able to continuously speed. DC motor, although also continuous speed control, but the price is expensive, the volume weight is too large.

- Q: Asus notebook power adapter how to open

- Hi respectful ASUS users The power adapter can not be disassembled, and if your machine's power adapter is faulty, you can go to the local service center for testing.

- Q: Laptop power adapter (no power supply, but indicator light)

- Notebook power adapter can not charge, but the indicator light does not light the common reasons are: 1, the power adapter is broken or the connector is broken. 2, the power adapter output problem, no output or output is too low, can not give the computer charge. 3, the notebook charging interface is broken, not into the electricity charge. 4, the notebook power management circuit out of the fault, resulting in can not charge.

- Q: Speed regulation method of three - phase asynchronous motor

- Change the number of pole pairs can be adjusted, in the way around the stator coil through the tap method can achieve two-speed. With the popularity of the inverter, three-phase asynchronous motor speed mostly with the inverter.

- Q: Fuji inverter motor set the number of poles will not have any effect?

- The number of motor poles set incorrectly, self-learning when the motor parameters are not correct, not the correct parameters of the motor. Inverter control speed is not accurate, and the motor will heat, can not work properly.

- Q: How to choose a Siemens inverter for a 5.5KW three-phase motor (2 pole)?

- Beijing easy to create a website with Siemens inverter selection manual! You can log on online! Or contact them directly, they will give you professional answers!

- Q: Is the laptop power adapter hot?

- Third, the power of the nominal voltage than my books the battery voltage is much higher, not an accident, right? First of all, to know is that the power supply to the books and the battery power supply to the notebook is different. Battery-powered, the battery output is pure DC, very clean, the battery voltage is neither possible nor need to design a high, lithium battery chemical properties determine a cell output voltage can only be about 3.6V, so Many batteries are used in three cascade way, 10.8V also became a very popular battery voltage. Some batteries are slightly larger than the integer value of 3.6V, such as 3.7V or 11.2V, etc., in fact, to protect the battery. Power supply, the situation is more complex, first of all need to add voltage to further regulation filter to ensure that the power performance is not very good in the case of stable work, the voltage regulator after the two parts of the city, all the way to the work of the power supply , The other way to the battery charge to the part of the power supply to the battery when the same power supply, and the part of the battery charge through the battery charge control circuit can be added to the battery, the control circuit can be very complex, so the power The voltage must be greater than the cell voltage to have sufficient capacity to supply the charge control circuit to the units. Finally the voltage actually added to the cell will never be the nominal voltage of your power supply. Rest assured.

- Q: Motor a speed, the inverter will burn what is going on, the inverter is a large yuan

- Note that the quality of the inverter is not ye, and now this situation is already very rare, it is recommended to replace the inverter brand, you can use Bosch Rexroth, the British Witten, Huichuan, Senlan, Haili Pu, Ou Rui, etc. Branded.

Send your message to us

High Medium Voltage Drive 11KV 280KW RMVC4000-A110/360 VFD

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 100000 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches