High-effect MSG evaporation crystallization device

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 200 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1Company Information

FEICHENG JINTA MACHINERY CO., LTD.is the largest manufacturer of alcohol, fuel ethanol and DDGS high protein feed complete equipment in China which is capable to design, manufacture, install and adjust 3000t-500000t alcohol complete equipment in the turnkey project .

2.Product Description:

MSG evaporation crystallization device which we make is a high-efficient heat exchanging equipment used in alcohol, solvent, food ferment, pharmaceutical, petrochemical, refrigeration, organic chemistry, metallurgical industry, suitable for convection heat transfer of liquid to liquid,gas to gas, gas to liquid.

3.New Technology Description:

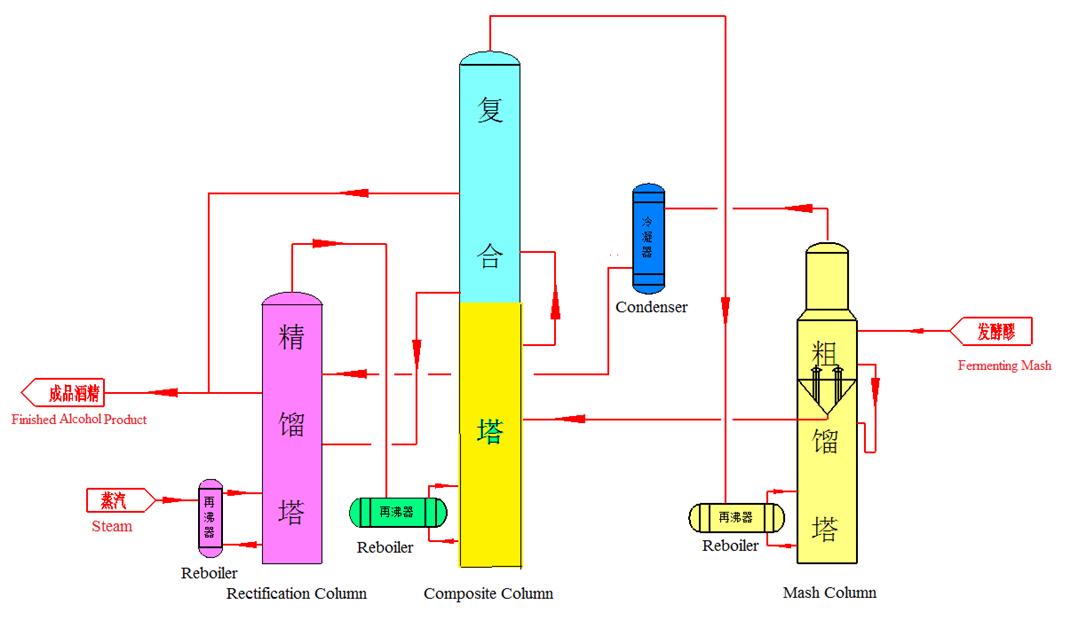

Five-Column Three-Effect Distillation Process

The key of this process is the heating methods,the steam heats one column directly and transfers the heat to other 4 columns to achieve three-effect thermal coupling and energy-saving effects.

Double-Mash-Column Three-Effect Distillation Process

The key of this process lies in the heating methods: the steam heats one column directly and transfers the heat to other 2 columns to achieve three-effect thermal coupling and energy-saving effects. The advantage of this process is energy-saving;it saves over 40% steam

4. Production Capability

1).Our company was established in the 1950s, designed and manufactured the first stainless steel distillation column in China, now We own advanced machining equipment and product testing equipment

1).Our company was established in the 1950s, designed and manufactured the first stainless steel distillation column in China, now We own advanced machining equipment and product testing equipment

2).Our company has 16 production workshops which can produce 6 full sets of equipment (including crushing section, liquefying saccharification section, fermentation section, distillation section and DDGS section) per month.

5. Designed capability

1). We own Design License of Special Equipment D1 & D2 Class; Manufacture License of Special Equipment A2 Class; Design License of Special Equipment GC Class.

1). We own Design License of Special Equipment D1 & D2 Class; Manufacture License of Special Equipment A2 Class; Design License of Special Equipment GC Class.

2).Our company achieves more than 20 patent certificates on distillation, DDGS, and other fields.

3).Our company owns ASME certification, ISO 9001 Quality System Certification, ISO 14001 Environmental Management System Certification & GB/T28001 Occupational Health and Safety Management System Certification

6.Contact us

Name:vick liang

Email:vick@jintagroup.com

Phone: 86 13953842508

Tel: 86-538-3393266

Fax: 86-538-3399066

Skype: vicklwk

QQ: 496443614

- Q: The evaporator is made of raw material

- The main agent and curing agent in the weight ratio of 1: 2-6 dubbed the two-component epoxy polyurethane anti-corrosion coating layer, the evaporator aluminum tube coating layer after drying and vulcanization treatment, and finally the evaporator aluminum tube

- Q: What is the high pressure tube?

- Cooling tube for the high pressure, thick tube for the low pressure pipe. Air conditioning works: compressors, condensers, throttle, evaporator,

- Q: How to get these three things on the compressor. Condenser, throttle, evaporator

- The compressor comes out of the condenser, the condenser comes out of the throttle valve, the throttle valve is the evaporator, the evaporator returns to the compressor.

- Q: Is it the same thing as an air conditioner evaporator?

- Is not the same thing at all. The evaporator is much more sophisticated than the heat exchanger.

- Q: What kind of condenser and evaporator are there for cooling water

- System failure and compressor damage. Vertical coil heat exchanger structure is simple, cheap, but pay special attention to the cooling problem when the cooling plate heat exchanger heat transfer efficiency is high, generally 3 times the shell and tube,

- Q: The more detailed the difference between the condenser and the internal structure of the evaporator

- In the condenser design, should be sub-channel, different road entrance should be as close as possible, exports should also be as close as possible, imports and exports should also be as far as possible to avoid due to heat loss and loss of part of the heat transfer to avoid uneven distribution of traffic

- Q: Why air conditioning evaporator will freeze

- Severe icing is the temperature setting is too low or temperature control failure, so that the compressor non-stop cooling.

- Q: How to understand the air conditioning principle in this sentence "compressor inhalation from the evaporator has absorbed the heat into the gaseous low-pressure low-temperature refrigerant

- Flow to the evaporator (pipe suddenly thicker), liquid into a gaseous (rapid pressure reduction), the temperature dropped to achieve the cooling effect.

- Q: Car air conditioning evaporator is not the bigger the better

- The main influencing factors are the displacement and efficiency of the compressor (the bigger the better

- Q: I would like to ask why the water-cooled unit of the condenser and the evaporator is into the water into the way out, what will happen,

- There are two benefits: one, regardless of the size of the water, the container must be full of water (no air); Second, just the opposite of the flow of refrigerant, will get the best heat exchange,

Send your message to us

High-effect MSG evaporation crystallization device

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 200 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot Searches

Related keywords