High Alumina Bricks for Industrial Kilns

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

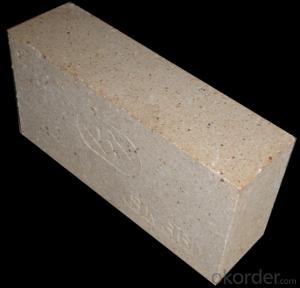

High Alumina Bricks for Industrial Kilns

Composite of High Alumina Bricks

High Alumina Bricks are classified according to alumina content ranging from 48% to 90%.

Main Features of High Alumina Bricks

Low thermal conductivity

Excellent acid and base slagging resistance

High refractoriness

Excellent thermal shock resistance

Excellent mechanical strength

Application of High Alumina Bricks

commonly used in blast furnace, hot blast furnace, the roof of electric furnace, teeming ladle, rotary kiln, regenerator, etc

High Alumina Bricks Images

Specification of High Alumina Bricks

HIGH ALUMINA BRICK---ALP85 | |

Apparent Porosity (%) | ≤18 |

Bulk Density (g/cm3) | ≥2.85 |

Cold Crushing Strength (Mpa) | ≥80 |

Modulus Of Rupture (Mpa) | ≥20 |

Refractoriness Under Load (0.2 Mpa)(℃) | 1450 |

Permanent Linear Change (%) | 1500℃×3h -0.5 ~+0.5 |

Chemical Composition (%) |

|

Al2O3 | ≥82 |

Fe2O3 | ≤1.5 |

P2O5 | ≤3 |

FAQ of High Alumina Bricks

Q1:Are you a manufacture or trader?

A:Factory+trade(mainly factories, at the same time, we operates other related products).

Q2:Can we visit your factory?

A:Sure,welcome at any time, seeing is believing.

Q3:What's the MOQ of trial order?

A:No limit, We can offer the best suggestions and solutions according to your condition.

Q4:Which payment terms can you accept?

A:T/T,L/C are available for us.

Q5:After an order is confirmed, when to deliver?

A:15-25days after deposit.

Q6:Is your company accept customization?

A:We have own factory and excellent technical team, and we accept OEM service.

Q7:How about your company's certification?

A:ISO9001 and Test Report, also we could apply other necessary certification.

Q8:How to solve the quality problems?

A:If the products are not confirmed to customer samples or have quality problems, our company will be responsible to make compensation for it.

- Q: How much is the bending temperature aluminum silicon carbide brick for torpedo car

- The product has the advantages of high temperature, little creep, strong corrosion resistance and good thermal shock resistance, and is suitable for large and medium-sized hot blast stoves.

- Q: What are the main components of high alumina bricks?

- High alumina brick materials according to the main mineral phase can be divided into: aluminum silicate minerals, such as sillimanite, kyanite, andalusite, and synthetic mullite.

- Q: Application characteristics of high alumina brick

- Load softening temperature. The softening temperature of high alumina brick products decreases with the increase of silica and alkali metal oxide content, but is higher than that of clay brick products, which is about 1420 - 1530 degrees centigrade. Al2O3. The softening temperature of corundum brick with content greater than 95% can reach above 1600 DEG C.

- Q: What are the reasons for the decline in the performance of high alumina bricks when we use high alumina refractory bricks?

- The brick Pei boring and time. 6, Pei brick kiln installed between the brick and the brick Pei order, Pei and kiln top, kiln wall gap etc.. 7, high alumina brick kiln plan, and the lack of edges and corners of the scene should be avoided.

- Q: The difference between aluminium refractory and magnesia refractory

- Therefore, the difference between the two is a neutral, one is alkaline, the original product is different naturally.

- Q: What is the density of a super high alumina brick and what is the price?

- Super high alumina brick, alumina content of 80% bricks, bulk density of 2.7g/cm3 or more, the factory price of about 1900 yuan

- Q: What are ordinary bricks, refractory bricks, hollow bricks?

- Light yellow or brownish. The utility model is mainly used for laying smelting furnaces, and can withstand high temperature between 1580 DEG C and 1770 DEG C. Also called brick. Refractory material of a certain shape and size. According to the preparation process can be divided into bricks, brick, electric melting brick (Rong Zhuzhuan), the refractory insulating bricks; according to the shape and size can be divided into standard brick, brick, brick and other specific type. It can be used as high temperature building materials and structural materials for construction kilns and various thermal equipments, and can undergo various physical, chemical and mechanical changes at high temperature. For example, refractory clay brick, high alumina brick, brick, brick etc..

- Q: The difference between light high alumina brick and heavy aluminum brick

- Lightweight high alumina brick, also called high alumina insulation brick. Alumina content of 48% or more, mainly from mullite and glass phase or corundum composition of lightweight refractory. Volume density 0.4 - 1.35g/cm3. Porosity 66% - 73%, compressive strength 1 - 8MPa. Better thermal shock resistance. Usually, a high alumina clinker is added with a small amount of clay. After grinding, it is poured and shaped in the form of slurry by gas generation or foam method, and it is fired at 1300 - 1500 DEG C. Sometimes industrial alumina can be used instead of some bauxite clinker. Used for lining and insulation of masonry kilns, as well as for areas where there is no strong, high temperature molten material erosion and erosion. When contacting the flame directly, the surface contact temperature shall not be higher than 1350 degrees centigrade.

- Q: What kind of material is the general metal case?

- Generally speaking, the outer surface of the case is usually made of a steel plate of more than 1 millimeters. The thickness and the material of the steel plate are directly related to the rigidity of the case, as well as the capability of sound insulation and anti electromagnetic radiation. The regular manufacturers of the chassis plate thickness not less than 1.3mm, but there are also some small manufacturers with a thickness of only about 1mm steel, we do not need the ruler to the amount, as long as you put him up, the more weight in the same volume of the chassis is better, in addition, we can also use the finger bomb case shell. If you can hear the crisp percussion sound proof of the casing plate is thin and brittle, if you hear is relatively dull and heavy sound that the chassis material must be good, good general steel plate coated with a layer of thin zinc (bright part), so it can withstand high strength, impact resistance, hardness high elasticity. The frame parts of the chassis are made of high quality materials with high hardness. They are bent into angle shapes or strip shapes. We can shake the chassis frame of the case by hand. Good chassis should be relatively stable, and inferior chassis light is easy to shake. When choosing, we should also pay attention to the outer edge of the case and the edge of the inner bracket. Whether the incision is smooth or not, a good case will not appear in the case of rough edges, sharp edges, burrs and so on. While the poor case appears above phenomenon, often appear when installing the blood splattered". Generally speaking, the chassis must go through the corresponding grinding process before leaving the factory. The edge of the flat plate some burr, edges and corners are rounded, the corresponding fold some corner. When you install such a case, you don't worry about cuts, and some rough, poorly built cabinets tend to scratch your hands.

- Q: Use of high alumina refractory bricks?

- Because of the high Al2O3 high aluminum products, low impurity content, the formation of fusible vitreous body less so than the clay brick high load softening temperature, but because mullite crystallization has not formed the network organization, so the load softening temperature is not high silica brick.

Send your message to us

High Alumina Bricks for Industrial Kilns

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords