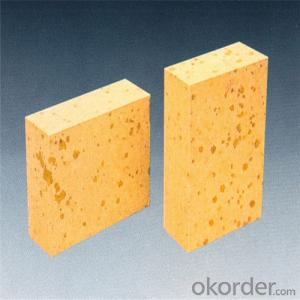

Silica High Alumina Brick Fireclay Brick

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Specifications

Refractory high alumina brick

High bulk density

High compressive strength

High refractoriness

Best PricE

Features:

1) A variety of specifications available.

2) Satisfy various technical request.

3) Lower medium spoilage.

4) Good insulation performance and high temperature resistance.

5) Stiffness texture.

6) Used in all electric products and electric heating products.

7) OEM, ODM and OBM are welcomed.

customer's drawings, samples and performance requirement are highly appreciated.

| Performance | |||||

| Item | Unit | 95 Al2O3 | 96 Al2O3 | 99 Al2O3 | |

| Physical Characteristics | Bulk density | g/cm3 | 3.6 | 3.6 | 3.9 |

| Water absorption | % | 0 | 0 | 0 | |

| Mechanical Characteristics | Flexural strength | Mpa | 320 | 340 | 360 |

| Hardness Vickers | Gpa | 12.2 | 13.5 | 15.6 | |

| Elastic modulus | Gpa | 280 | 320 | 370 | |

| Poisson’s ratio | - | 0.22 | 0.23 | 0.23 | |

| Thermal Characteristics | Linear expansion coefficient | (200C-5000C) 10-6/0C | 7.1 | 7.2 | 8 |

| Thermal conductivity | w/(m.k) | 16 | 24 | 32 | |

| Specific Heat | *10-3J/(kg*K) | 0.78 | 0.78 | 0.9 | |

| Electrical Characteristics | Dielectric constant (1MHZ) | - | 9 | 9.4 | 9.9 |

| Dielectric loss angle | *10-4 | 15 | 5 | 1 | |

| Dielectric strength | *106V/m | 12 | 15 | 15 | |

| Processing technology | |||||

| Process range (mm) | |||||

| Outside Diameter | 1---300 | ||||

| Inside Diameter | 0.5---300 | ||||

| Length | 0.5---1200 | ||||

| Accuracy of working (mm) | |||||

| Perpendicularity | 0.01 | ||||

| Concentricity | 0.01 | ||||

| Roundness | 0.005 | ||||

| Straightness | 0.005 | ||||

| Parallelism | 0.01 | ||||

| Planeness | 0.005 | ||||

| Roughness | 0.05 | ||||

| Fit clearance | 0.005 | ||||

- Q: The hot blast stove when the temperature did not rise against the brick interface decreased

- Insulation of hot blast stove, key insulation silica brick hot stove, hot blast stove is shutdown or need repairing in blast furnace.

- Q: Semisilica brick interpretation

- High temperature volume stability. Volume change is small.

- Q: Such purpose and scope please give me detailed points thank you because I am learning stage

- Acid refractory brick is mainly composed of tridymite and cristobalite and quartz and a small amount of residual glass phase.

- Q: What role does silica play in refractories?

- The natural mineral of silica is called quartz. In refractories, silica and siliceous refractory materials contain more silica. Silica is acidic at high temperature, and siliceous refractory can resist acid slag corrosion

- Q: Can iron oxide be used as refractory material?

- Iron oxide can not be used as refractory material, but it can be used as refractory additive. Iron oxide can be used as pigment

- Q: Why is the three oxidation of two silicon is very harmful impurities in silica brick

- Heating calcination is the best way to extend this sort of impurity removal. Remove impurities

- Q: Why is the highest brick coke oven temperature measuring point temperature not exceeding 1450

- That is because the brick load softening point the maximum temperature is 1450 degrees.

- Q: Why in the production of the brick to detect the volume density

- Fast density test, please consult an instrument.

- Q: High temperature refractory material?

- Special materials often use AZS brick (i.e. corundum brick), corundum brick, magnesia chrome bricks, silicon carbide, silicon nitride bonded silicon carbide, nitrides, silicides, sulfide, boride, carbide and other non oxide refractory materials; calcium oxide, chromium oxide, alumina, Magnesium Oxide, beryllium and other refractory materials. Insulation refractories are often used diatomite products, asbestos products, insulation board. Unshaped refractories are often used refractory castable, refractory clay, refractory ramming material, refractory plastic and fettling material, fire resistance, gunning, refractory cast material, fireproof coating, lightweight refractory castable, gun mud.

- Q: Physical solid waste disposal

- Too much addition will reduce the refractory and mechanical strength, increase porosity, so the amount of waste brick should not be too much.

Send your message to us

Silica High Alumina Brick Fireclay Brick

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords