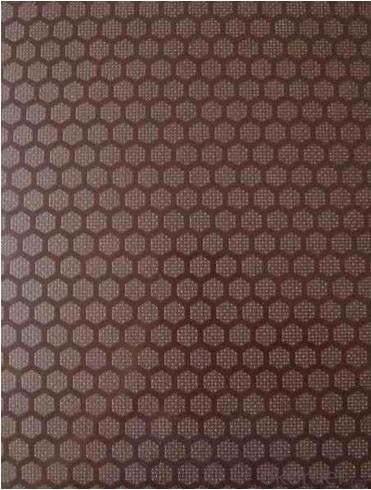

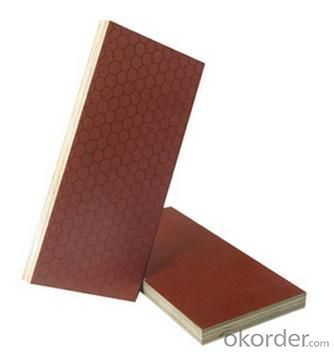

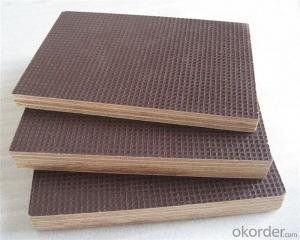

1/2 OSB Plywood Hexagonal Design Anti-Slip Film Faced Plywood

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 300 m³

- Supply Capability:

- 10000 m³/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Description:

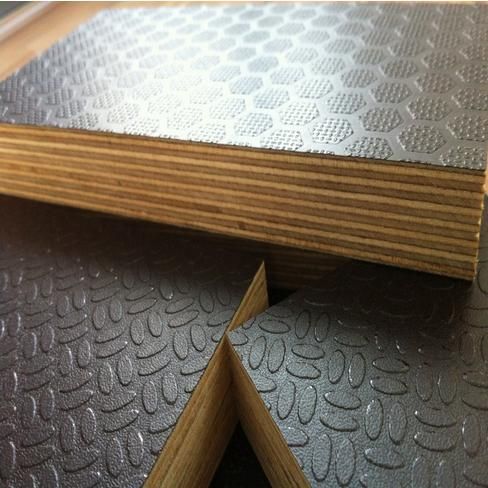

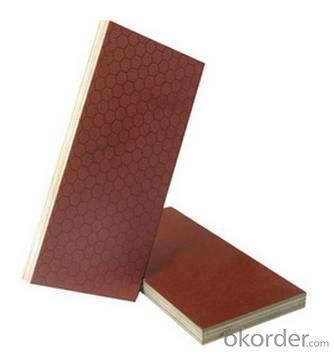

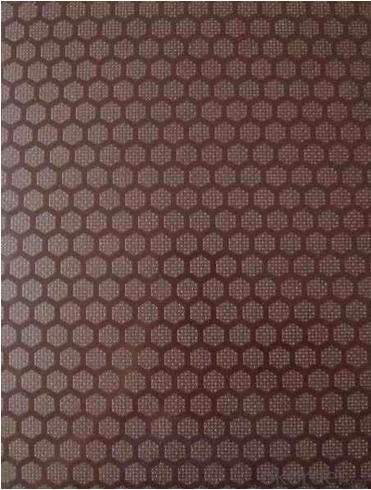

Hexagonal Design Anti-Slippery Film Faced Plywood are widely used in construction repeatly and sometimes for stage boards..

Characters:

Anti-Slipping, Different styles/Designs, Light, easy to install and disassemble; be used recyclely, waterproof.

Products Details:

Detailed Specification:

Product name:Hexagonal Design Anti-Slippery Film Faced Plywood

Size:1220x2440mm,1250x2500mm

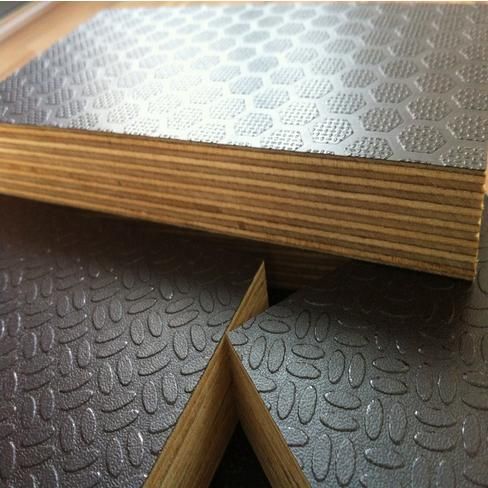

Hot press: two times hot press

Thickness:9mm,12mm,15mm,18mm,20mm,21mm,25mm

Tolerance: +/-0.5mm

Core:Poplar,Eucalyptus,hardwood,combi

Film:brown with/without logo

Glue:MR,WBP(melamine),WBP(phenolic)

Grade:First class

Moisture:below 14%

Usage:outdoor,concrete forms,formwork,shuttering,construction,etc

Package:Inter packing: 0.20mm plastic bag

Outer packing: pallets are covered with thin plywood or carton and then 4*6 steel straps for strength.

Conveyance:

20’GP:8 pallets/23m³

40’GP:16 pallets/45m³

40’HQ:18 pallets/57m³

Delivery time:

Within 15 days on receipt of deposit or original L/C

Min Order:1X40’FCL

Payment:L/C at sight, T/T(30%deposit)

Supply ability:5000 cubic meters/month

Main market: Middle east,Africa,UAE,Qatar,Oman,Russian,etc

FAQ:

Q1.How many times it can be used?

A1: It mainly depends on hotpress times, quality of raw materials and type of Glue. Normally, Melamine glue poplar core two times hot press film faced plywood can be used about 5-8times.

- Q: according to the use of plywood can be divided into needle plywood and broadleaf plywood.

- Ⅲ, Ⅳ plywood moisture content of not more than 15%). ③ quality. Finished products should have rectangular straight edges and obvious edges and corners;

- Q: Why plywood is cheaper than solid wood

- commonly known as: multi-layer board) is one of the commonly used furniture materials, is a wood-based panel. Plywood is cut from the wood section into a veneer or cut from the wooden square cut into thin wood

- Q: triple? Nail gun Self-tapping screws? Cork Or other?

- usually its table and the inner plate symmetrically arranged in the center layer or plate on both sides

- Q: What are the further processing of plywood?

- Resin Treated Plywood Paste Plywood Plywood with resin impregnated or impregnated with other methods.

- Q: How do you choose plywood in plywood production?

- But should be described in the name of the product, such as "cedar veneer plywood", or "fir slices plywood", or "cherry wood trim".

- Q: What harm does the plywood factory work?

- Occupational acute benzene poisoning is the workers in the professional activities, short-term inhalation of high-dose benzene vapor caused by the central nervous system suppression as the main manifestation of systemic diseases

- Q: Ordinary plywood is divided into four categories

- According to different density, divided into 80, 70, 60 three categories. Quality level for the premium, one, two three

- Q: Multilayer board, also known as three plywood and plywood

- different layers of different names. According to the thickness of 3-9 cm, can also be called 3-9 PCT board

- Q: Material for the plywood defects which

- false heartwood heartwood sound wood center part of the color is different from the normal wood, often dark brown or reddish-brown, usually its density and hardness are relatively large.

- Q: Today, most of the furniture is made of wood, pine, bakelite and popla

- As these high quality woods become increasingly scarce and expensive, people begin to make furniture with easier access to wood, and those good wood is already very rare

Send your message to us

1/2 OSB Plywood Hexagonal Design Anti-Slip Film Faced Plywood

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 300 m³

- Supply Capability:

- 10000 m³/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords