Heavy Duty Woven Geotextile Fabric Specifications for Needle Punched Nonwoven Geotextile in Highway Construction

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 20000 m²

- Supply Capability:

- 1500000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Application of Needle Punched Nonwoven Geotextile for Highway Construction:

1. Water conservancy projec: seawall, dike,river canal engineering;Reservoir reinforcement engineering; Reclamation engineering; Flood control engineering.

2.Highway,railway and airport project: soft foundation reinforcement; Slope protection; Pavement structure layer reflective crack prevention; Drainage system; Greening belt.

3.Electrical engineering : Nuclear infrastructure;Thermal power ash dam project;Hydropower project.

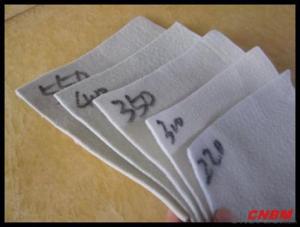

Technical Data Sheet of Needle Punched Nonwoven Geotextile for Highway Construction:

Index Spec.

Article | 100 | 150 | 200 | 250 | 300 | 350 | 400 | 450 | 500 | 600 | 800 | |

1 | Quality error in unit area,% | -6 | -6 | -6 | -5 | -5 | -5 | -5 | -5 | -4 | -4 | -4 |

2 | Thickness,mm≥ | 0.8 | 1.2 | 1.6 | 1.9 | 2.2 | 2.5 | 2.8 | 3.1 | 3.4 | 4.2 | 5.5 |

3 | Width error,% | -0.5 | ||||||||||

4 | Breaking strength,KN/m≥ | 4.5 | 7.5 | 10.0 | 12.5 | 15.0 | 17.5 | 20.5 | 22.5 | 25.0 | 30.0 | 40 |

5 | Elongation at break,% | 40~80 | ||||||||||

6 | CBR puncture strength,KN≥ | 0.8 | 1.4 | 1.8 | 2.2 | 2.6 | 3.0 | 3.5 | 4.0 | 4.7 | 5.5 | 7.0 |

7 | Effective aperture 090(095),mm | 0.07~0.2 | ||||||||||

8 | Vertical permeability coefficient , cm/s | K X (10-4-10-3) K=1.0~9.9(K=1.0~9.9) | ||||||||||

9 | Tearing strength,KN≥ | 0.14 | 0.21 | 0.28 | 0.35 | 0.42 | 0.49 | 0.56 | 0.63 | 0.70 | 0.82 | 1.1 |

FAQ:

What is the main application of Needle Punched Nonwoven Geotextile for Highway Construction?

The main application of our Needle Punched Nonwoven Geotextile for Highway Construction is as follows: The highway, railway, soil-stone dam, breakwater, airport, backfill soil of retaining wall, slope protection, etc.

Where is your main market?

Our main market is in Middle East, South America and some African countries.

What is your advantages for Needle Punched Nonwoven Geotextile for Highway Construction?

One of the largest manufacturer of Needle Punched Nonwoven Geotextile for Highway Construction with advanced equipment, big production capacity and excellent quality.

Over the past decade a greater emphasis has been placed on the development and manufacturing of geosynthetic textiles. While the geosynthetics industry is comparatively new, it has already created products with applications in a wide range of industries including geotechnical, transportation, hydraulic, embankment management, and mining. In many cases, a single geosynthetic textile can solve or improve multiple civil engineering problems simultaneously.

The first example of a geosynthetic textile application is the use of a prefabricated pocket style vertical drain made from a nonwoven filter jacket specialized as a PVD filter material. The purpose of this product was to reduce the time needed for construction by quickly discharging water in the ground which speeds up the soil consolidation process. Overall, it proved to reduce construction time and speed up the consolidation of soft ground in a variety of different situations including road construction, the development of building sites, construction of gas and oil storage facilities, and bank revetment.

The second example of how geosynthetic textiles can provide solutions to civil engineering problems is the polyester woven geotextile mat. It is created from a high tenacity polyester filament which is highly dense. This particular geosynthetic textile has been used to reinforce soft ground and embankments, separate layers of sand and soft ground, prevent the uneven settlement of soft ground, and securing a safe path of travel for heavy equipment across soft ground.

The third example is a silt curtain or fence created by geosynthetic textiles. A silt curtain is installed in the water to prevent the spread of environmentally dangerous contaminants. These contaminants often result from coastal and Riverside construction projects although it can also be used in the event of an open water spill or leak. It has been shown effective at preventing the spread of fine soil and sand induced by construction. It can also prevent the contamination of the nearby seaports and help preserve sea farming and area beaches.

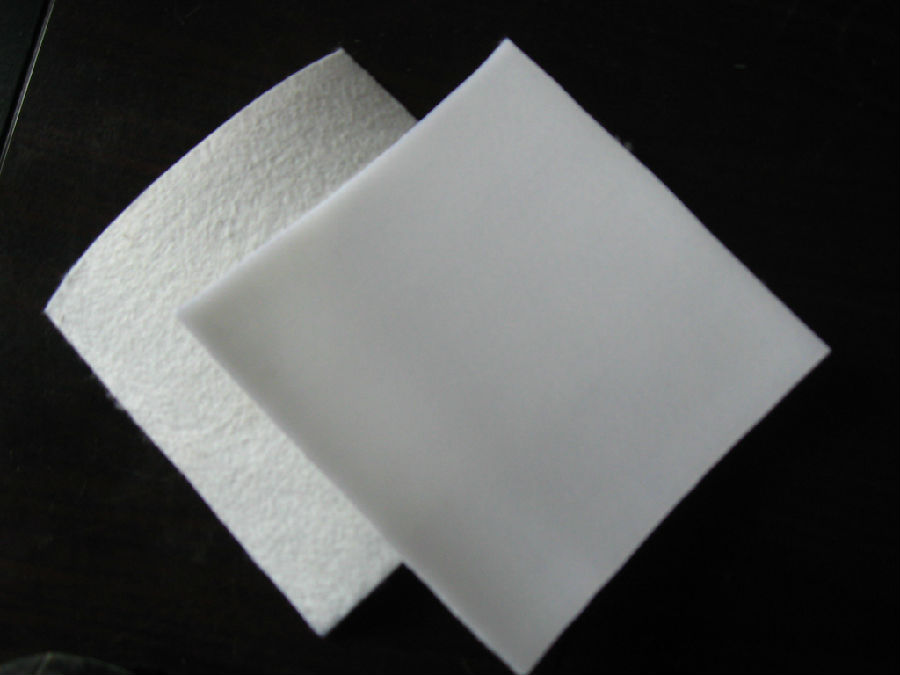

The fourth and final example of geosynthetic textiles assisting with civil engineering problems is the polyester needle punched nonwoven geotextile. It is typically made of continuous filament fiber to promote fast drainage and filtration. It has been used to help prevent landslides, control erosion on banks, protect waterproof layers in landfills, prevent road tracking, and protect waterproof sheets and tunnels.

There is no doubt geosynthetic textiles will continue to play a greater role in finding workable solutions to civil engineering problems across the globe. As their production continues to scale, prices will decrease which will lead to an increase in availability as well as further research and development.

- Q: Introduction of filament geotextile

- Filament geotextile: filament geotextile polyester filament acupuncture non-woven geotextile, without chemical additives, nor heat treatment, is environmentally friendly building materials.

- Q: Are high geotextiles harmful to people?

- High-tech geotextile is not harmful to people. High-iron geotextile for strong, tensile, anti-friction coefficient, anti-oxidation time and other indicators are very strict, it can be said that geotextile applications so far the highest requirements. The raw materials for the production of geotextile are polypropylene fiber, polypropylene fiber civilian use: can be pure or wool, cotton or viscose blended mixed woven to produce a variety of clothing. Can be used for weaving all kinds of knitwear such as socks, gloves, sweaters, knitted pants, dish cloth, mosquito cloth, was expo, warm filler, diaper wet. Industrial use: geotextile, industrial filter cloth, carpet, fishing nets, canvas, hose, concrete reinforced materials, industrial fabrics, nonwovens and so on. So do not worry, high-speed rail geotextile with environmental requirements, no harm to the human body.

- Q: 200g / m2 geotextile how to enter the inspection test

- (Including: wide strip tensile test, trapezoidal tear strength test, CBR bursting strength test, puncture, mechanical properties, including mechanical properties (including: gross weight per unit area, amplitude measurement, thickness measurement); mechanical properties (including: (Including vertical penetration test (constant head method), hydrostatic pressure test, effective pore size test (dry sieve method), clogging test, etc.). Related testing standards: 1. Short wire acupuncture geotextile with reference to GB / T-1998.2. Filament acupuncture geotextile with reference to GB / T-2008.3. Filament woven geotextile GB / T-2008.4 Welded film woven geotextile with reference to GB / T-1998

- Q: How do geotextiles contribute to soil filtration?

- Geotextiles contribute to soil filtration by acting as a barrier that allows water to pass through while preventing the movement of soil particles. They help to retain sediment, filter out pollutants, and improve water quality, ultimately enhancing the overall filtration and drainage capabilities of the soil.

- Q: Geotextile and geogrid difference

- Different geotextile used to prevent seepage, geogrid used to reinforce the geotextile is mainly used to seepage, isolation, geogrid are generally used in reinforced reinforcement, the two are essential differences in the use of the process Sometimes used in the same project, such as high-speed, railway and other engineering production grid is made of polypropylene, polyvinyl chloride and other polymer polymer by thermoplastic or molded two-dimensional grid or a certain height of the three-dimensional Dimensional grid grid, when used as a civil engineering, known as geogrid. Engineering applications: roads, railways, abutments, approach roads, docks, dams, slag and other soft soil foundation reinforcement, retaining walls and road surface cracking engineering and other fields. Fiberglass mesh used in the external walls, wall paint, the main material to prevent the junction of different mortar and other plastering material cracking, hollowing. Local node reinforcement will also be used. Geotextile has excellent filtration, drainage, isolation, reinforcement, anti-seepage, protection, with light weight, high tensile strength, good permeability, high temperature, anti-freeze, anti-aging, corrosion resistance. Common non-woven fabrics, water layer inside the use, polyethylene polypropylene waterproof also used.

- Q: What are the specifications for geotextiles in civil engineering projects?

- The specifications for geotextiles in civil engineering projects typically include factors such as the material type, weight, strength, permeability, and durability. These specifications ensure that the geotextile selected is suitable for the intended application, whether it's erosion control, filtration, separation, or reinforcement. Additionally, the specifications may also cover aspects like installation requirements, testing methods, and compliance with industry standards to ensure the geotextile performs effectively and meets the project's requirements.

- Q: What are the different geotextile permeability testing methods?

- There are several different geotextile permeability testing methods, including the constant head method, falling head method, and gradient ratio method.

- Q: Manufacture of geotextile machinery

- Non-woven needle machine, I am specializing in the production of geotextiles

- Q: How do geotextiles improve the performance of geomembranes?

- Geotextiles improve the performance of geomembranes by acting as a protective barrier that prevents direct contact with the underlying soil or other abrasive materials, thereby reducing the risk of punctures or damage. They also provide additional reinforcement and stability, distributing loads more evenly across the geomembrane. Additionally, geotextiles allow for better water drainage and filtration, preventing the accumulation of water pressure and enhancing the overall performance and longevity of the geomembrane system.

- Q: 400 grams per square meter of non-woven geotextiles how much money

- According to your technical parameters, the specific number of professional geotextile manufacturers to answer, power to discuss!

Send your message to us

Heavy Duty Woven Geotextile Fabric Specifications for Needle Punched Nonwoven Geotextile in Highway Construction

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 20000 m²

- Supply Capability:

- 1500000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords