HDPE Biaxial Geogrids for Road Construction

- Loading Port:

- Qingdao

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 20000 m²

- Supply Capability:

- 10000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

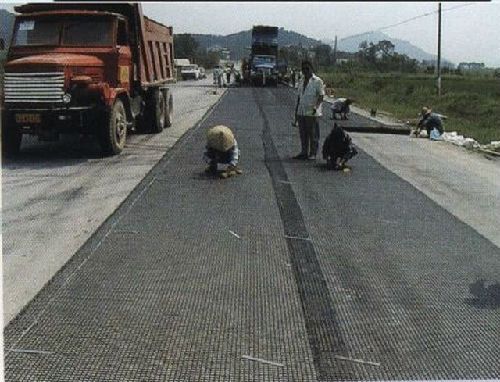

1.HDPE geogrid is a kind of new favorable earthwork base material to strengthen the road surface and roadbed.

2.This product is made by HDPE. The products after surface covering own the favorable property of alkali resistance and aging resistance.

3.This product is also used to strengthen the soft land, such as railway, airport,irrigation work, and dyke, etc, and the roadbed.

HDPE Uniaxial geogrid Product Poperties

Specification | 50 | 60 | 80 | 90 | 100 | 110 | 120 | 150 | 160 | 190 | 220 |

Width( m) | 1 or 1.1 or 2.5 or 3 | ||||||||||

Tensile strength≥(kN/m) | 50 | 60 | 80 | 90 | 100 | 110 | 120 | 150 | 160 | 190 | 220 |

Elongation ≤(%) | 11.5 | ||||||||||

Tensile strength at 2% strain≥(kN/m) | 12 | 14 | 21 | 24 | 26 | 29 | 33 | 41 | 47 | 55 | 64 |

Tensile strength at 5% strain≥(kN/m) | 23 | 27 | 40 | 45 | 50 | 55 | 65 | 81 | 93 | 110 | 127 |

- Q: What is a geotextile mattress?

- The utility model relates to a mattress structure, which is formed by the connection of the geotextile to a certain size, and the structure of the utility model is hinged and connected with the precast concrete plate to form a punching structure

- Q: Are geogrids suitable for use in seismic zones?

- Yes, geogrids are suitable for use in seismic zones. Geogrids are engineered materials that provide reinforcement and stability to soil. They are designed to improve the performance of soil structures in various conditions, including seismic events. Geogrids can help increase the tensile strength and stability of soils, reducing the risk of soil liquefaction and enhancing the overall resilience of structures in seismic zones.

- Q: How do geogrids improve the load-bearing capacity of soil?

- Geogrids improve the load-bearing capacity of soil by providing reinforcement and stabilization. They interlock with the soil particles, creating a stronger and more cohesive structure. This prevents the soil from shifting or settling, effectively distributing the load and increasing its overall strength.

- Q: Are geogrids suitable for use in ground reinforcement for wind farms?

- Yes, geogrids are suitable for use in ground reinforcement for wind farms. Geogrids are commonly used in various civil engineering applications, including soil stabilization and reinforcement. They provide tensile strength to the soil, preventing erosion and enhancing the stability of the ground. In the case of wind farms, where the ground needs to support heavy equipment and withstand strong winds, geogrids can effectively reinforce the soil, ensuring the long-term stability and durability of the infrastructure.

- Q: What is the GDL geogrid

- GDL geogrid is uniaxial plastic geogrid, uniaxial plastic geogrid with high density polyethylene (HDPE) as raw materials, pressure into a sheet by extrusion and punching network rules, and then the longitudinal stretch into the geogrid.

- Q: Can geogrids be used in reinforcement of underground utility corridors?

- Yes, geogrids can be effectively used in the reinforcement of underground utility corridors. Geogrids provide structural support and stability to the soil surrounding the utility corridors, minimizing the risk of settlement and shifting. They improve the load-bearing capacity of the soil, preventing damage and potential collapse of the underground utility infrastructure. Additionally, geogrids can help distribute loads more evenly and reduce stress concentration, ensuring the long-term durability and performance of the utility corridors.

- Q: Are geogrids effective in stabilizing coastal dunes?

- Yes, geogrids are effective in stabilizing coastal dunes. Geogrids provide reinforcement and prevent erosion by acting as a support system for the sand particles. They help to maintain the shape and stability of coastal dunes, protecting them from wind and water forces.

- Q: Can geogrids be used in retaining walls?

- Yes, geogrids can be used in retaining walls. Geogrids are commonly used as a reinforcement material in retaining walls to enhance their stability and strength.

- Q: Are geogrids suitable for use in reinforced retaining walls?

- Yes, geogrids are suitable for use in reinforced retaining walls. Geogrids are designed to provide stability and reinforcement to the soils behind retaining walls, helping to distribute the loads evenly. They enhance the overall strength and integrity of the wall, preventing soil erosion and reducing the risk of wall failure. Geogrids are commonly used in various types of retaining walls, such as gravity walls, cantilever walls, and reinforced soil walls, making them a reliable and effective solution for reinforcement.

- Q: See details of the application of design code for railway embankment geosynthetics TB10018-2006

- See details of the application of design code for railway embankment geosynthetics TB10018-2006

1. Manufacturer Overview

| Location | Shandong, China |

| Year Established | 2002 |

| Annual Output Value | Above US$ 20 Million |

| Main Markets | 20.00% North America 15.00% South America 15.00% Eastern Europe 10.00% Southeast Asia 10.00% Northern Europe 10.00% South Asia 10.00% Western Europe 5.00% Africa 5.00% Mid East |

| Company Certifications | ISO9001:2000; |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Qingdao Port |

| Export Percentage | 41% - 50% |

| No.of Employees in Trade Department | 6-10 People |

| Language Spoken: | English; Chinese; |

| b) Factory Information | |

| Factory Size: | Above 80,000 square meters |

| No. of Production Lines | Above 10 |

| Contract Manufacturing | Design Service Offered; Buyer Label Offered |

| Product Price Range | High; Average |

Send your message to us

HDPE Biaxial Geogrids for Road Construction

- Loading Port:

- Qingdao

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 20000 m²

- Supply Capability:

- 10000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords