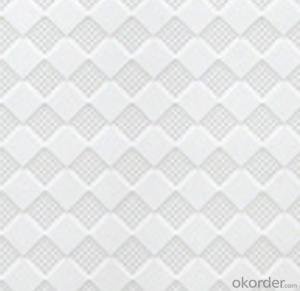

Textured Gypsum Ceiling PVC Laminated

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 6000 m²

- Supply Capability:

- 10000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Plasterboard is made of high-grade environmental protective gypsum raw material, no harming to human body, and it has some performances: (such as environmental protection, fire-proof, moisture-proof, light and high intensity).

Plasterboard is easy to install, and its decoration effect is good. Its special indoor temperature adjustment function can provide a comfortable living environment. It is the first choice to interior decoration.

Plasterboard is made of high-grade environmental protective gypsum raw material, no harming to human body, and it has some performances: (such as environmental protection, fire-proof, moisture-proof, light and high intensity).

Product Applications:

+ Furred ceiling

+ Interior wall cover

+ Partition wall

1.Thermal insulation

2.Fire-resistant performance for fire-proof plasterboard

3.Water-resistant performance for water-proof plasterboard

4.Easy installation (it can be easily sawed,planed,holed and sticked)

5.Special respiratory function (it has a great mass of ting holes

Product Advantages:

1.Thermal insulation

2.Fire-resistant performance for fire-proof plasterboard

3.Water-resistant performance for water-proof plasterboard

4.Easy installation (it can be easily sawed,planed,holed and sticked)

5.Special respiratory function (it has a great mass of ting holes and its function of moisture-adsorbing and moisture-dismissing)

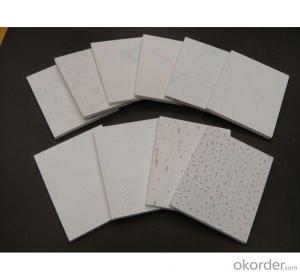

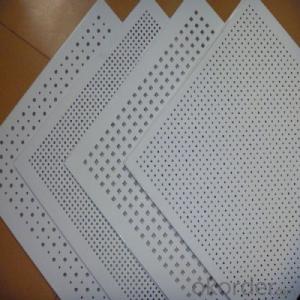

Main Product Features:

Material: Gypsum Board, non asbestos, sulfate free

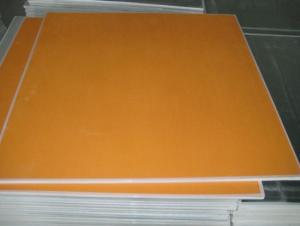

Surface: High quality PVC/Vinyl

Backside: High quality aluminized PET foil

Edges: Square

Weight /cbm: 780kgs/m3

Tolerance: Length: ± 1.0mm, Width: ± 1.0mm,

Thickness: ± 0.5mm

NRC: 0.1 - 0.3

Light reflection: 0.75

Standards: Gypsum boards are manufactured according to EN-520, ASTM C1396, E84 and E96

Humidity resistance: up to 95% relative

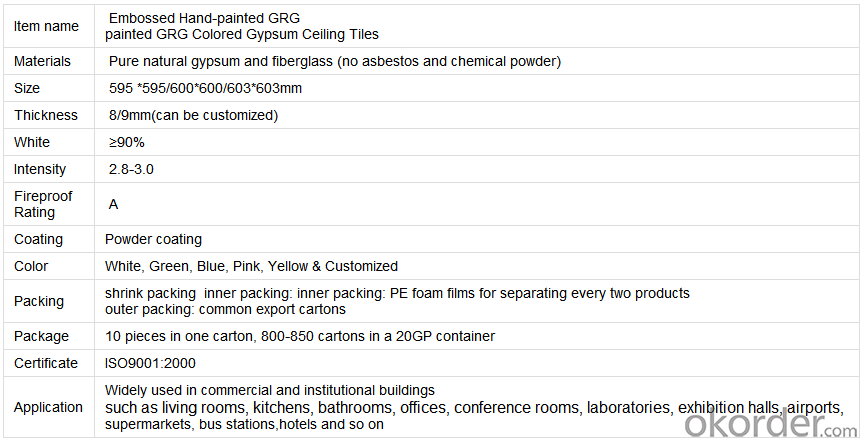

Product Specifications:

FAQ:

1. What kind of certificate do you have?

ISO9001, ISO14001, CE, SONCAP, VOI(CO), CARB, FSC, CE

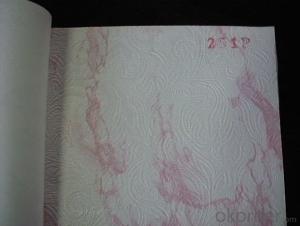

2. What color can you produce?

You can choose the design you want

3. How about the delivery time?

20-25 days after receiving prepayment or L/C

For the samples, it will be prepared ASAP.

4. What's the MOQ and Payment Terms?

Minimum Ordering Quantity: 2X20ft Container

Payment Terms: T/T or L/C at sight

Images:

- Q: Want to use gypsum board ceiling ceiling ceiling fan, do not know whether it is feasible.

- If you want to hang the fan is relatively heavy, it would cut the gypsum board area is relatively large (a person's head can be stretched out) after the hanging bar (metal hanging bar) and the original building structure ceilings and installed pre-embedded structural parts, Seal the top, and finally install the ceiling fan on the embedded parts.

- Q: The company specializes in operating the light steel keel gypsum board. Kelp board. Paint keel installation. Factory price wholesale. Professional construction personnel to undertake office buildings. Supermarket. Shops and various business premises design and installation of one-stop service

- Green wood, green wood, aluminum ceilings, aluminum ceilings, aluminum grille, sandwich color steel, rock wool color plate, clean ceiling, gypsum ceiling, light steel keel, antistatic floor, PVC glue Board, gypsum trim, mineral wool board ceiling, waterproof board, Eide board, wall materials and other new decorative materials

- Q: The house is engaged in decoration, the balcony has been installed on the ceiling, but the workers said that four nails hanging in the "gypsum ceiling" fixed on the fixed, I had gypsum board door in advance also set a wooden grid, but due to gypsum board barrier, Can not see the wooden lattice, the workers said, "Ghost know that my four nails nail up, will be tied in the air or wood? Think about it also makes sense ah, but I really want to be a drying rack on the balcony ah ~ ~ Otherwise, after life more inconvenient? ~

- You can not put it in any other way

- Q: Is it possible to drive a separate downlight to a gypsum ceiling? After all, long-term fever, will not bake black? Is there any action?

- No, now are led ceiling, fever is not very serious.

- Q: Our family is 2 meters high 6, the ceiling is also used to do? How high is it?

- Ceiling is the roof of the living environment of the top decoration. Simply put, refers to the decoration of the ceiling, is an important part of interior decoration. Ceiling with insulation, insulation, sound insulation, sound absorption of the role, but also electrical, ventilation and air conditioning, communications and fire, alarm pipeline equipment and other projects hidden layer. Home decoration ceiling is a common part of home improvement. The ceiling is different according to the material of the decorative plate, and the classification is not the same. Ceiling decoration materials is the main basis for distinguishing the name of the ceiling, mainly: light steel keel gypsum board ceiling, gypsum board ceiling, mineral wool board ceiling, plywood ceiling, profiled long strip of aluminum slab ceiling, Glass ceiling, aluminum honeycomb perforation sound-absorbing panels such as ceiling. In the choice of ceiling decoration materials and design programs, to follow the two materials, solid, safe, and beautiful, practical principles.

- Q: How to do the ceiling gypsum board

- Identification of aluminum slab plate, in addition to pay attention to the surface finish, but also to observe the thickness of the board is uniform, hand pinch about the board feel, flexibility and toughness is good.

- Q: Built-in lamp ceiling of the living room at least how much thickness, only enough possession of light. Built-in lamp ceiling of the living room at least how much thickness, was enough possession of light? Brick wall standard What is the thickness of the cement sand? living room, bathroom, kitchen, restaurant and other ceiling height at least how much?

- Brick wall of the standard specifications are: sintered solid brick, 240 × 115 × 53, concrete block 190 × 190 × 390; sintered porous brick: 190 × 190 × 90; brick brick mortar thickness is generally 6 ~ 8mm, the most Thick 10mm; living room, bathroom, kitchen, restaurant and other ceiling at least the height of 100mm,

- Q: Decorative light steel keel how many flat for an inspection lot

- Light steel keel, is a new type of building materials, with the development of China's modernization drive, light steel keel is widely used in hotels, terminals, bus stations, stations, playgrounds, shopping malls, factories, office buildings, old buildings Building renovation, interior decoration, roof and other places. Light steel (paint) keel ceiling with light weight, high strength, to adapt to water, shock, dust, noise, sound absorption, constant temperature and other effects, but also has a short duration, easy construction and so on. Light steel keel surface should be galvanized rust, the double-sided galvanized: excellent products not less than 120g / m * m.

- Q: How high is the ceiling?

- Followed by the surrounding ceiling, the way to stay in the middle of the lamp. This ceiling can be used wood plywood molding, designed into a variety of shapes, matched with spotlights and downlights, in the middle of the ceiling with a more innovative ceiling, will make people feel room space increased. This design method for the larger living room, the effect will be better.

- Q: The top angle dimension width standard is generally how many living room two layers of plaster top angle line

- Gypsum board, ceiling, gypsum fiberboard, such as a plate said, referring to the difference between the two diagonal, is 5MM, the difference between the more laugh the better, the smaller the difference, indicating that the board Founder.

Send your message to us

Textured Gypsum Ceiling PVC Laminated

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 6000 m²

- Supply Capability:

- 10000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords