PVC Square Gypsum Ceiling Board Quotes - Gypsum Ceiling Board PVC Laminated 991 for Hot Sale

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 4000 m²

- Supply Capability:

- 250000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

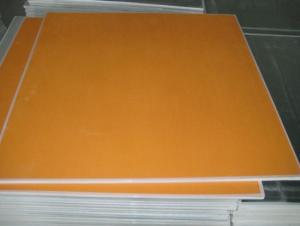

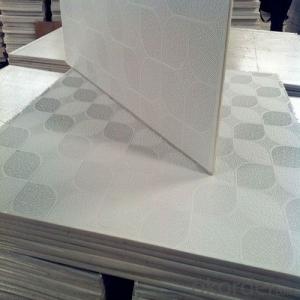

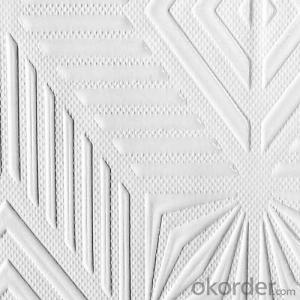

Gypsum ceiling tiles are made of incombustible gypsum board, PVC facing as well as aluminum foil backing. The aluminum foild backing has thermal insulation properties while the PVC facing provide you various choices with different designs.

Product Applications:

+ Furred ceiling

+ Interior wall cover

+ Partition wall

Product Advantages:

1.Thermal insulation

2.Fire-resistant performance for fire-proof plasterboard

3.Water-resistant performance for water-proof plasterboard

4.Easy installation (it can be easily sawed,planed,holed and sticked)

5.Special respiratory function (it has a great mass of ting holes and its function of moisture-adsorbing and moisture-dismissing)

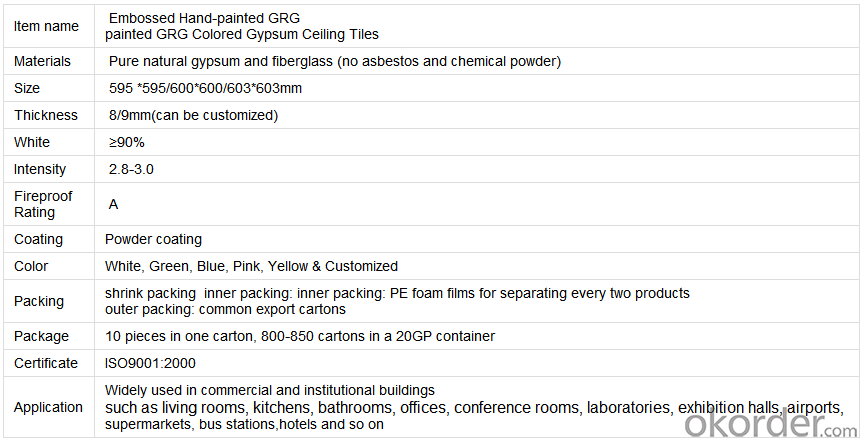

Main Product Features:

Material: Gypsum Board, non asbestos, sulfate free

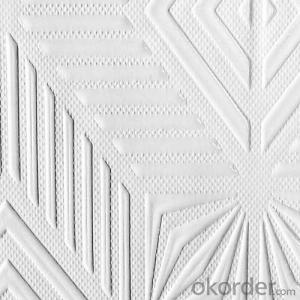

Surface: High quality PVC/Vinyl

Backside: High quality aluminized PET foil

Edges: Square

Weight /cbm: 780kgs/m3

Tolerance: Length: ± 1.0mm, Width: ± 1.0mm,

Thickness: ± 0.5mm

NRC: 0.1 - 0.3

Light reflection: 0.75

Standards: Gypsum boards are manufactured according to EN-520, ASTM C1396, E84 and E96

Humidity resistance: up to 95% relative

Product Specifications:

FAQ:

1. What kind of certificate do you have?

ISO9001, ISO14001, CE, SONCAP, VOI(CO), CARB, FSC, CE

2. What color can you produce?

You can choose the design you want

3. How about the delivery time?

20-25 days after receiving prepayment or L/C

For the samples, it will be prepared ASAP.

4. What's the MOQ and Payment Terms?

Minimum Ordering Quantity: 2X20ft Container

Payment Terms: T/T or L/C at sight

Images:

- Q: Did the screw punch break the ceiling gypsum?

- Split, the above is a small piece of a small box, the grid can be pushed up, pushed open, the line, the installation. Place a small board on the ceiling of the camera's mounting position, and the camera fixing screw is screwed onto the board.

- Q: Where is the professional market? Where is the main producing area?

- There are many kinds of gypsum board Whether the paper gypsum board. And paper gypsum board, waterproof is gypsum board. To see what you want to die I plant production is no paper gypsum board. The main producing areas are generally more in the provincial capital cities.

- Q: what is jointless gypsum ceiling??what are the other terms used for it?

- Primarily used in Europe, Jointless gypsum ceilings refer to installing a sheathing type gypsum board over an existing framing platform then installing panels usually plastic over the gypsum using a beaded plastic T molding that installs into the joints of the unfinished gyp board. Pain in the butt, not very desirable to the Americans historically. But, products may have changed since the last time I seen it. GL

- Q: The house is engaged in decoration, the balcony has been installed on the ceiling, but the workers said that four nails hanging in the "gypsum ceiling" fixed on the fixed, I had gypsum board door in advance also set a wooden grid, but due to gypsum board barrier, Can not see the wooden lattice, the workers said, "Ghost know that my four nails nail up, will be tied in the air or wood? Think about it also makes sense ah, but I really want to be a drying rack on the balcony ah ~ ~ Otherwise, after life more inconvenient? ~

- You can not put it in any other way

- Q: Our family is 2 meters high 6, the ceiling is also used to do? How high is it?

- Can not do the ceiling to do at least 10 centimeters too much to suppress the space is too low, people are hard to accept unless you are like a Japanese back on the floor activities do not stand up and suggest that you directly posted wallpaper on the market with the top Wallpaper is very beautiful

- Q: How to do the ceiling gypsum board

- Identification of aluminum slab plate, in addition to pay attention to the surface finish, but also to observe the thickness of the board is uniform, hand pinch about the board feel, flexibility and toughness is good.

- Q: My family living room layer of the plateau 3030MM, hanging 2-level ceiling hanging chandelier position 2800, is now the gypsum board top with the original roof 23CM spacing How to install crystal chandeliers, chandeliers are heavier, carpentry said with the expansion of the top Fixed, I would like to ask 23CM gap can play up the expansion of silk? As well as the staircase position is now inclined to the top of the hanging now, the above empty 1 m 4 high, wood workers at that time to leave a ceiling with the boom that the lamp fixed on top. Can I? The ceiling are finished now all the latex paint are brush, and buy online buyers say that the poor installation, so to help!

- Simple point approach 1. In the installation of chandeliers to open the position of 60MM empty, with a long impact drill drill in the ceiling drilling, with the top of the expansion of the kind of expansion wire can be fixed. 2 Woodworking boom is the hanging wire of light steel keel? If it can be used.

- Q: When would you like to use a single gypsum board when using double gypsum board

- You are not called the law itself is not professional, gypsum board are double-sided, double-sided face coated with gypsum core paper. Even the coated gypsum ceiling is also double-sided, side PVC, side aluminum foil. Hebei Oasis Machinery Factory production of such machinery, specializing in the production of gypsum products machinery, I heard that all exported to the rest of the world for many years, if you need to answer with the professional. Let's talk to them I remember a man called Xiao Wu's business, very good attitude quite good young people, promising.

- Q: Gypsum board ceiling shot hole how to make up

- The gypsum board cut to the place where the keel exposed in a corresponding playing gypsum board to make up nine can remember to be sure to leak the keel to make your plaster board fixed to the keel

- Q: How to accept gypsum board ceiling?

- (1) gypsum board surface should be flat, no pollution, fracture, missing edge angle, hammer and other defects, seams should be uniform. (2) put on the installation of gypsum board shall not have leakage, through, Qiaojiao phenomenon. (3) perforation plate spacing should be arranged neatly, perforation should be vertical dry surface, Gui edge shape of the right angle of the plate, the side should be at right angles to the board. (4) decorative gypsum board front should not affect the decorative effect of the pores, stains, cracks, missing angle, uneven color and incomplete pattern defects. (5) Gypsum board surface should be flat, for ripples, grooves, stains and scratches and other defects, according to the provisions of the test method should be consistent with the provisions of Table 4-3-12. (6) sound absorption perforated gypsum board should not have the shadow, to the use and decoration effect of the defects, the paper gypsum board as the substrate plate should not be damaged, scratches, stains, bumps, paper peeling and other defects; To decorative gypsum board for the substrate plate should not have cracks, stains, pores, missing angle, uneven color and other defects. Concealed sound-absorbing material should be anti-scattered measures. (7) embedded decorative gypsum board front can not affect the decorative effect of the pores, stains, cracks, missing angle. Acceptance of skeleton structure The skeleton structure in the decoration works is mainly the ceiling skeleton, the partition wall or the wall skeleton and the decorative body skeleton. The types of skeletons are wooden skeleton, angle iron skeleton and light steel keel skeleton.

Send your message to us

PVC Square Gypsum Ceiling Board Quotes - Gypsum Ceiling Board PVC Laminated 991 for Hot Sale

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 4000 m²

- Supply Capability:

- 250000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords