Grade 309_316_316L Stainless Steel Flat Bar with High Quality

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Grade 309_316_316LStainless Steel Flat Bar with High Quality

Details of Grade 309_316_316L Stainless Steel Flat Bar with High Quality

Name | 200,300,400 series Stainless Steel Flat Bar |

Shape | Flat Bar |

Standard | GB/ASTM/SAE/AISI/DIN/JIS/EN/BS |

Surface Treatment: | Black/Peeling/Polished/Machined |

Delivery Condition: | Hot Rolled or Forged/Peeled or Black Surface |

Test | SGS/UT 100% Elements Testing |

Certificate: | ISO/Mill Certificate |

Service: | 24 hours online service / |

more than 20 years trading and manufacture | |

Quality Assurance: | the third party inspection, such as SGS, BV, TUV…etc. is acceptable |

Packaging Details: | Seaworthy Packaging or as per customer's packing instruction |

steel flat bar grade | 201/304/304L/309L/316/321 |

steel flat bar standard | GB, ASTM, AISI, EN, JIS |

steel flat bar thickness | 3mm-12mm |

steel flat bar width | 19mm-140mm |

steel flat bar length | 2m~6m or as customer requirement |

steel flat bar technique | Slitting hot rolled steel coil |

Chemical Composition of Grade 309_316_316L Stainless Steel Flat Bar with High Quality

Grade and Main chemical composition% | |||||||||

| C | Si | Mn | P≤ | S≤ | Cr | Mo | Ni | Other |

201 | ≤0.15 | ≤1.00 | 5.5-7.5 | 0.06 | 0.03 | 16-18 | - | 3.5-5.5 | N≤0.25 |

304 | ≤0.08 | ≤1.00 | ≤2.00 | 0.045 | 0.03 | 18-20 | - | 8-10.5 | - |

304L | ≤0.03 | ≤1.00 | ≤2.00 | 0.045 | 0.03 | 18-20 | - | 13-Sep | - |

309S | ≤0.08 | ≤1.00 | ≤2.00 | 0.045 | 0.03 | 22-24 | - | 15-Dec | - |

316 | ≤0.08 | ≤1.00 | ≤2.00 | 0.045 | 0.03 | 16-18 | 3-Feb | 14-Oct | - |

321 | ≤0.08 | ≤1.00 | ≤2.00 | 0.045 | 0.03 | 17-19 | - | 13-Sep | Ti≥5×C |

CNBM Introduction of Grade 309_316_316L Stainless Steel Flat Bar with High Quality

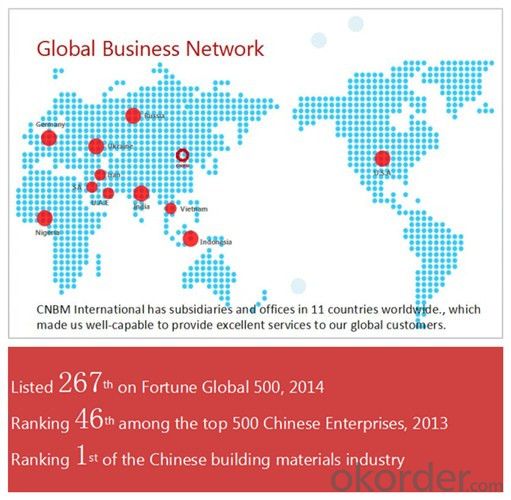

CNBM International Corporation is the most import and export platform of CNBM group(China National Building Material Group Corporation) ,which is a state-owned enterprise, ranked in 270th of Fortune Global 500 in 2015.

With its advantages, CNBM International are mainly concentrate on Cement, Glass, Iron and Steel, Ceramics industries and devotes herself for supplying high quality series of refractories as well as technical consultancies and logistics solution.

After-sale service |

|

Advantages

|

|

Packaging & Delivery of Grade 309_316_316L Stainless Steel Flat Bar with High Quality

Packaging Detail | Sea worthy packing /as per customer's packing instruction |

Delivery Detail | 15 ~ 40 days after receiving the deposit |

Products Show

FAQ:

Are you a trading company or manufacturer? | Manufacturer |

What’s the MOQ? | 3 metric ton |

What’s your delivery time? | 15-35 days after downpayment received |

Do you Accept OEM service? | Yes |

what’s your delivery terms? | FOB/CFR/CIF |

What's the Payment Terms? | 30% as deposit,70% before shipment by T/T |

Western Union acceptable for small amount. | |

L/C acceptable for large amount. | |

Scrow ,Paybal,Alipay are also ok | |

Why choose us? | Chose happens because of quality, then price, We can give you both. Additionally, we can also offer professional products inquiry, products knowledge train (for agents), smooth goods delivery, excellent customer solution proposals. |

What's your available port of Shipment? | Main Port, China |

What’s your featured services? | Our service formula: good quality+ good price+ good service=customer's trust

|

Where are your Market? | Covering more than 160 countries in the world |

- Q: Are steel flat bars heat-treatable?

- Yes, steel flat bars can be heat-treated. Heat treatment is a process used to alter the properties of steel by subjecting it to specific temperature conditions. This process can be used to increase the hardness, strength, and durability of the steel. Heat treatment involves heating the steel to a specific temperature, holding it at that temperature for a certain period of time, and then cooling it at a controlled rate. By carefully controlling the heating and cooling cycles, the structure and properties of the steel can be modified. This allows steel flat bars to be customized to meet specific requirements for different applications.

- Q: What is the typical shear strength of steel flat bars?

- The typical shear strength of steel flat bars can vary depending on the specific grade and thickness of the material. However, in general, steel flat bars have a shear strength ranging from 40,000 to 60,000 pounds per square inch (psi). It is important to note that these values may differ based on factors such as the heat treatment, composition, and manufacturing processes used for the steel flat bar.

- Q: How do steel flat bars compare to stone flat bars?

- Steel flat bars and stone flat bars have distinct differences in terms of material composition, physical properties, and applications. Steel flat bars are made from alloyed steel, offering high strength, durability, and corrosion resistance. They are versatile and widely used in construction, manufacturing, and engineering projects due to their excellent load-bearing capabilities and ability to withstand extreme conditions. On the other hand, stone flat bars are typically made from natural or engineered stone materials, which provide a unique aesthetic appeal and can be used in decorative applications. However, stone flat bars may have limitations in terms of strength and flexibility compared to steel flat bars. Therefore, the choice between steel and stone flat bars depends on the specific purpose and desired characteristics required for the intended use.

- Q: Are steel flat bars commonly used in the transportation industry?

- Yes, steel flat bars are commonly used in the transportation industry. They are often utilized in the construction of various types of vehicles, including cars, trucks, and trailers. Steel flat bars offer numerous advantages, such as their strength and durability, which make them an ideal choice for supporting heavy loads and withstanding the rigors of transportation. Additionally, steel flat bars can be easily formed and welded, allowing for flexibility in design and construction. Overall, steel flat bars play a crucial role in the transportation industry, providing structural support and ensuring the safe and efficient movement of goods and people.

- Q: Can steel flat bars be used in the manufacturing of machinery parts?

- Steel flat bars are a viable option for the production of machinery parts. With their versatility and wide range of applications across various industries, including machinery manufacturing, they can be easily manipulated into different shapes and sizes through cutting, shaping, and welding. This adaptability makes them perfect for the creation of machinery parts. Furthermore, steel flat bars possess exceptional strength, durability, and resistance to wear and tear, enabling them to endure the stresses and loads experienced by machinery parts during operation. Moreover, these bars can undergo surface treatments or coatings to boost their corrosion resistance, guaranteeing the longevity of the machinery parts. Overall, due to their mechanical properties and versatility, steel flat bars are frequently utilized in the manufacturing of machinery parts.

- Q: What are steel flat bars?

- Steel flat bars are long rectangular pieces of steel that have a flat surface and sharp edges. They are commonly used in construction, manufacturing, and industrial applications. These bars are made from various grades of steel, such as carbon steel or stainless steel, and are produced through a process called hot rolling or cold drawing. Steel flat bars have a wide range of uses due to their versatility and strength. They are often used as structural supports, braces, or framing components in buildings and bridges. In manufacturing, they can be used as base plates for machinery, brackets, or as raw material for fabrication. Additionally, steel flat bars are frequently utilized in the automotive, aerospace, and marine industries. The flat surface of these bars allows for easy welding, cutting, and machining, making them highly adaptable to different projects and applications. They can be shaped, bent, or drilled to fit specific requirements. The sharp edges of steel flat bars also provide stability and structural support when used in construction or as load-bearing components. Steel flat bars come in various sizes, thicknesses, and lengths, allowing for customization and flexibility in their use. They are typically available in standard dimensions and can be purchased from steel suppliers or metal fabrication shops. Overall, steel flat bars are essential building materials that offer strength, durability, and versatility. They are widely used in a range of industries and applications, making them a crucial component in many construction and manufacturing projects.

- Q: How do steel flat bars contribute to the overall longevity of structures?

- Several factors contribute to the overall longevity of structures, and steel flat bars play a crucial role in this regard. They offer structural strength and stability, making them essential elements in construction projects. The high strength-to-weight ratio of steel enables the creation of efficient and lightweight structures, reducing the load on the foundation and other supporting elements. Furthermore, steel flat bars possess excellent corrosion resistance, which is vital for structures exposed to harsh environmental conditions. Corrosion can gradually weaken a structure, necessitating expensive repairs or even replacement. However, steel's inherent resistance to corrosion helps prevent this degradation, ensuring the longevity of the structure. Additionally, steel flat bars exhibit remarkable durability, enabling them to withstand heavy loads and extreme weather conditions. They are resistant to warping, twisting, or bending, ensuring the stability and integrity of the structure over time. This durability reduces the need for frequent maintenance or reinforcement, thus extending the structure's lifespan. Moreover, steel flat bars offer versatility, as they can be easily fabricated and customized to meet specific design requirements. This flexibility empowers architects and engineers to create innovative and efficient designs capable of withstanding various stresses and strains. The adaptability of steel flat bars to different shapes and sizes ensures seamless integration into the overall construction, enhancing its longevity and performance. In conclusion, steel flat bars significantly contribute to the overall longevity of structures by providing strength, durability, corrosion resistance, and versatility. Their robustness and ability to withstand heavy loads and adverse conditions make them an ideal choice for construction, ensuring that structures can endure the test of time.

- Q: What are the different types of edge finishes available for steel flat bars?

- There are several different types of edge finishes available for steel flat bars, including square, rounded, beveled, chamfered, and decorative profiles. These finishes can enhance the appearance, safety, and functionality of the steel flat bars depending on the specific requirements and applications.

- Q: Are steel flat bars suitable for making brackets or supports for solar panels?

- Yes, steel flat bars are suitable for making brackets or supports for solar panels. Steel is a strong and durable material that can withstand the weight and stress of solar panels. Additionally, steel flat bars provide stability and rigidity, ensuring that the solar panels remain securely in place. The flexibility of steel allows for easy customization and fabrication of brackets or supports to fit specific solar panel sizes and mounting requirements. Furthermore, steel has excellent resistance to corrosion, which is essential for outdoor installations where solar panels are exposed to various weather conditions. Overall, steel flat bars are a popular choice for making brackets or supports for solar panels due to their strength, durability, stability, and corrosion resistance.

- Q: What industries commonly use steel flat bars?

- Steel flat bars find widespread use across a diverse range of industries owing to their versatility and durability. Construction, manufacturing, automotive, infrastructure, and engineering are some of the sectors that frequently employ steel flat bars. Within the construction industry, steel flat bars serve multiple purposes, functioning as support beams, frames, braces, and structural components in buildings and bridges. By offering strength and stability, they prove ideal for withstanding heavy loads and pressure. In manufacturing, steel flat bars play a crucial role in the fabrication of machinery, equipment, and tools. Their malleability allows for easy shaping and machining, enabling them to meet specific requirements and suit various manufacturing processes. The automotive industry relies on steel flat bars extensively, particularly in the production of vehicle chassis and body frames. These bars provide the necessary strength and rigidity to endure the stresses and strains endured by automobiles, ensuring safety and durability. Infrastructure projects such as highways, railways, and airports make extensive use of steel flat bars as well. They are employed in the construction of beams, columns, and other structural elements, furnishing the requisite strength to bear heavy loads and withstand environmental conditions. Engineering industries heavily depend on steel flat bars for a wide array of applications. These bars are commonly utilized in the fabrication of machinery, equipment, and components that necessitate strength, resilience, and versatility. Furthermore, they are used in constructing support structures, frames, and braces required for various engineering projects. In conclusion, steel flat bars are widely utilized in the construction, manufacturing, automotive, infrastructure, and engineering sectors. Their versatility, strength, and durability render them indispensable for numerous applications and projects within these industries.

Send your message to us

Grade 309_316_316L Stainless Steel Flat Bar with High Quality

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords