Globond Plus PVDF Solid Aluminium Panel

- Loading Port:

- Guangzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

GLOBOND Plus PVDF Solid Aluminium Panel

GLOBOND plus PVDF solid aluminium panel is made from excellent aluminium alloy plate, with PVDF painting of PPG or Akzo coated on the surface. The whole process of production adopts advanced NC panel beating device, NC multifunctional forming punch and the latest “Ransburgi” automatic electrostatic spray unit from Japan. Standard thickness:2.0㎜,2.5㎜,3.0㎜etc.

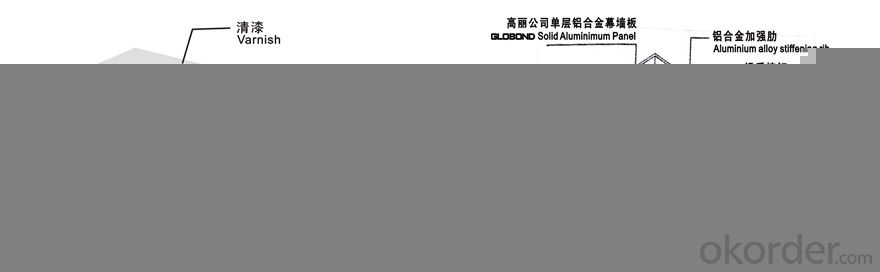

Product Structure

GLOBOND plus PVDF solid aluminium panel mainly consists of face plate, stiffening rib and hangers. If necessary, the back of the panel may fill in heat-insulation ore cotton. The hangers can be made by curving the face plate directly, or installed separately by aluminium profile. In order to ensure the flatness of the panel for long-term use, we install the stiffening rib on the back of face plate by bolts, to make it as a firm integral unit, thus enhancing the strength and rigidity of the material.

Application

Curtain wall of buildings, pillar, balcony, partition board, interior decoration, billboard, vehicle, furniture, exhibition booth, instrument enclosure, subway station, shipping vehicle ect.

Feature

1. Good formability, it can be formed to plane, arc, and complicated shape such as sphere and tower.

2. Hard to stain, easy to clean and maintain

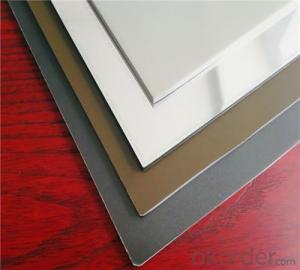

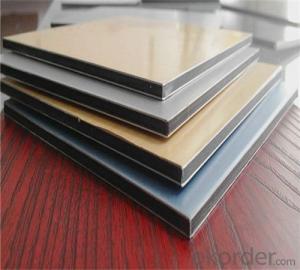

3. Wide range of colors optional, excellent decoration effect

4. Easy to recycle, no pollution

- Q: What are the folds of aluminum

- Aluminum-plastic composite board slot can generally open V-groove, U-slot, etc., several typical slotted as shown in Figure 1. Aluminum-plastic composite panel plate in the cutting board to take into account the size of the fold , Generally add about 25mm on each side. Cut the composite board needs four sides of the planing slot, that is cut to a certain width of the inner layer of aluminum and plastic layer, slot depth must be strictly controlled in the front aluminum plate at least 0.3mm thick plastic core To ensure that the aluminum-plastic composite panels have sufficient toughness to prevent the fold at the aluminum skin fracture, and then folded into a 90 ° angle, so the board surface weight and curtain wall at any time will be positive and negative wind load pressure by the four sides 0.5mm aluminum plate to bear, therefore, slotting is the aluminum-plastic composite panel panel of the weakest link, but also under the wind load under the first destruction of the site

- Q: 2017 aluminum-plastic board how the trend?

- Aluminum industry trend research report is through the aluminum plate industry market operation of many factors carried out by the investigation and analysis, grasp the aluminum plate industry market operation law, so the future development trend of aluminum industry characteristics, market capacity, competitive trends, sub-downstream market Demand trends and so on. First, the aluminum industry trends research report analysis of the main points include: 1) aluminum industry trends analysis. Through the analysis of the factors affecting the development of aluminum industry, the paper summarizes the characteristics of the overall operation trend of aluminum industry in the future; 2) predicts the development and trend of aluminum plate industry. Forecasting the development of production and its trends, which is the forecast of the supply of goods and its trends in the market; and 3) forecast the market capacity and change of the aluminum industry. Comprehensive analysis of the aluminum industry during the forecast production technology, product structure adjustment, forecast the demand for aluminum industry structure, quantity and trends. 4) forecast the aluminum market price changes. The price of the inputs and the sales price of the products are directly related to the profitability of the enterprises.

- Q: Aluminum veneer, aluminum-plastic plate and aluminum honeycomb curtain wall material is different

- Aluminum veneer is a layer of pure aluminum, aluminum-plastic plate is two layers of pure aluminum plate with pvc, honeycomb aluminum plate is between the two layers of aluminum plate with honeycomb, which is the most expensive honeycomb board, followed by Aluminum veneer, and finally aluminum-plastic panels, but the need for their own processing of aluminum-plastic panels, waste, short life, according to different processing, the price will be high. Effect and quality of the best is the honeycomb board (surface smooth, strong wind pressure), very on the grade, the use of the world less, the reason is the price is too high. Life and aluminum veneer is basically the same,

- Q: The required materials and prices together to make it clear, gray often thank you!

- Equipment such as slot machines, electric drill, table and so on

- Q: Japan Kobe Steel 5052 aluminum how much money a kilogram?

- 80 one kilogram

- Q: What are the factors that affect the price of aluminum-plastic panels? Big gods help out

- The price of aluminum-plastic plate is determined by a number of factors, mainly by the aluminum series, aluminum-plastic plate specifications, aluminum-plastic surface coating, aluminum-plastic plate thickness, aluminum-plastic plate thick aluminum, core material and other factors Impact. For example, from the surface of aluminum-plastic plate coating classification, can be divided into polyester aluminum-plastic plate and fluorocarbon aluminum-plastic plate. Fluorocarbon aluminum plate because of its good weather resistance (fluorocarbon, also known as PVDF), can keep 15 years does not fade, used for outdoor decoration; polyester aluminum plate (polyester, also known as PE) is used for indoor. As the fluorocarbon aluminum plate of the weather resistance is better, the price is higher than the polyester aluminum plate. Of course, the greater the thickness of aluminum-plastic or aluminum, the higher the price, the other is no different.

- Q: Aluminum-plastic plate roof is similar to the shape of many store signs, but the area is much larger times, like a box of the same, the middle of the keel or something, the other few are aluminum-plastic panels, combined into a cube. The most intuitive understanding of the container, or sealed the top of the truck compartment, surrounded by closed but the middle of the gap, so although the indoor water leakage point is fixed, and perhaps can not explain that only these leaks leak, there may be other places leaking , Because some points are low or just the seams are so leaked from these points. From this point of view, I do not know whether the need to clean up all the previous waterproof ointment, all re-silica gel?

- You do not talk about how fast cracks, a total of how long, that is, if a tube of glass glue enough you can consider using (that is, sticky fish tank that kind of glue) and winter is not suitable for waterproof work, And thermal expansion and contraction are problematic. Another cost of plastic should also be considered.

- Q: Aluminum panels are used in what areas, can not be more detailed.

- The aluminum-plastic panels were first developed by the German company Aiusingen and later improved by Forken and Aloca. 90 years later, the product quality gradually stable, reached a high level. As the aluminum-plastic plate is composed of two different materials (metal and non-metallic), it retains the original composition of materials (metal aluminum, non-metallic polyethylene plastic) the main features, but also to overcome the lack of raw materials , And then get a lot of excellent material properties. Such as luxurious and beautiful, colorful decorative; weathering, corrosion resistance, impact resistance, fire, moisture, heat insulation, sound insulation, light resistance; light, easy processing, easy handling, quick construction and other characteristics. These properties for the aluminum-plastic plate opened up a broad application prospects.

- Q: Which brand of aluminum veneer is good, where to find suppliers?

- Aluminum veneer is not necessarily a big big brand, mainly to see where you use, there is their own to understand the material is good or bad. Supplier of words if you want to recommend you or find their own near the building materials market it

- Q: What is the composition of aluminum-plastic panels?

- Aluminum-plastic plate is easy to process, forming a good material. But also for the pursuit of efficiency, for the time of the fine products, it can shorten the duration and reduce costs. Aluminum-plastic plate can be cut, cut, slotted, band saw, drilling, processing buried head, you can also cold bending, cold fold, cold rolling, can also riveting, screw connection or glue bonding.

Send your message to us

Globond Plus PVDF Solid Aluminium Panel

- Loading Port:

- Guangzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords