Fiberglass Facing E-Glass Emulsion Chopped Strand Mat

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 kg

- Supply Capability:

- 1000000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Glass Fiber E-glass Emulsion Chopped Strand Mat

Introduction:

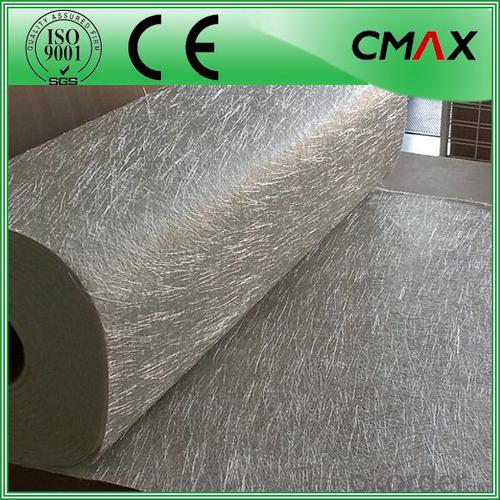

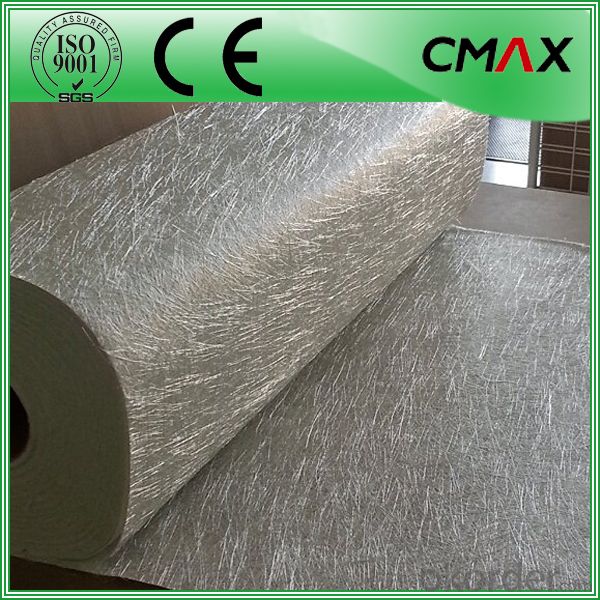

Fiberglass chopped strand mat is a non-woven E-or C-glassfiber mat, product manufactured by spreading continuous filament roving of 50mm in length randomly and uniformly in combination with polyester binder in powder form (or other binder in emulsion from). This product is characterized by good combination of resin, easy operation, good wet strength retention, good laminate transparency and low cost. It is suitable for the applications of hand lay-up FRP moldings, such as various sheets and panels, boat hulls, bath tubs, cooling towers, corrosion resistant, vehicles etc.

Function:

Fiberglass chopped strand mat is chopped using the "E" chopped glass and emulsion adhesive bond. It is suitable for hand lay and can enhance the unsaturaed ployester resins.

Product Features:

1. Uniform density ensures consistent fiberglass content and mechanical properties of the composites products.

2. Uniform powder distribution ensures good mat integrity, little loose fibers and small roll diameter.

3. Excellent flexibility ensures good mold ability with no spring back at sharp angles.

4. Fast and consistent wet-out speed in resins and rapid air lease reduce resin consumption and production cost and enhances productivity and mechanical properties of the end products.

5. The composite products have high dry and wet tensile strength and good transparency.

Technical Data:

| PRODUCT | TYPE | WEIGHT (G/M2) | WIDTH(MM) | ROLL WIEHGT (KG) | MOISTURE CONTENT(%) | BREAKAGE STRENGTH (N) | BINDER CONTENT(%) |

| EMC100 | E/C-GLASS | 100±30 | 200-3300 | 30-90 | < 0.2 | 170 | 8-13 |

| EMC150 | E/C-GLASS | 150±30 | 200-3300 | 30-90 | < 0.2 | 40 | 5-8 |

| EMC225 | E/C-GLASS | 225±30 | 200-3300 | 30-90 | < 0.2 | 60 | 4-7 |

| EMC300 | E/C-GLASS | 300±30 | 200-3300 | 30-90 | < 0.2 | 90 | 3-6 |

| EMC450 | E/C-GLASS | 450±30 | 200-3300 | 30-90 | < 0.2 | 120 | 2-5 |

| EMC600 | E/C-GLASS | 600±30 | 200-3300 | 30-90 | < 0.2 | 150 | 2-5 |

| EMC900 | E/C-GLASS | 900±30 | 200-3300 | 30-90 | < 0.2 | 180 | 2-5 |

Products Shows:

Certificates:

FAQ:

Is sample available ?

Yes, we provide the free samples, but customers themselves need pay the shipping fee

What's your MOQ?

Our MOQ is one 1*20' full container loading

How do you pack the fiberglass

(1) First, the mat is in roll packed in White PE fIlm.

(2) Then the rolls packed in the carton.

- Q: Is it safe and practical to use black fiberglass tissue as a material for bedding or curtains?

- <p>Black fiberglass tissue is not recommended for bedding or curtains due to its composition and properties. Fiberglass is a type of glass wool that can be irritating to the skin and respiratory system. It is typically used for insulation and not for direct contact with the skin or as a decorative material. For bedding and curtains, it's better to use materials that are soft, breathable, and safe for human contact, such as cotton, linen, or polyester blends.</p>

- Q: Is it possible to utilize black fiberglass scraps in the creation of new products made from recycled materials?

- <p>Yes, you can use black fiberglass scraps to make new products from recycled materials. Fiberglass recycling is possible, and it involves processes like shredding and grinding the scraps to create a material that can be used in new products. This can include composites for construction, automotive parts, or even as a filler material. However, it's important to note that recycling fiberglass can be challenging due to its composite nature, and not all types of fiberglass are easily recyclable. Proper recycling facilities and methods are required to ensure the process is both effective and environmentally friendly.</p>

- Q: What distinguishes black fiberglass tissue from other types of fiberglass tissue in terms of color, properties, and applications?

- <p>Black fiberglass tissue is distinguished by its color, which is typically achieved through the addition of pigments during the manufacturing process. This coloration can enhance UV resistance and provide a more aesthetically pleasing appearance in certain applications. Compared to other types of fiberglass tissue, such as white or colored ones, black fiberglass may also exhibit slightly different thermal properties due to the pigmentation. However, the core properties like strength, flexibility, and insulation capabilities remain largely the same across different colored fiberglass tissues. The choice between black and other types often comes down to specific industry requirements or aesthetic preferences.</p>

- Q: This question asks for an explanation of the production process of black fiberglass tissue.

- <p>Black fiberglass tissue is produced by weaving glass fibers into a fabric and then applying a black resin coating. The process begins with the melting of glass to form a molten substance, which is then extruded through a spinneret to create fine glass fibers. These fibers are woven into a fabric, similar to how textiles are made. After weaving, the fabric undergoes a sizing process where a black resin is applied. This resin not only gives the fiberglass its black color but also provides additional strength and protection to the fibers. The coated fabric is then cured to harden the resin, resulting in a durable and black-colored fiberglass tissue.</p>

- Q: What is the lifespan or strength of black fiberglass tissue?

- <p>The durability of black fiberglass tissue is quite high due to its resistance to various environmental factors. It is known for its strength, corrosion resistance, and ability to withstand high temperatures. Depending on the specific application and environmental conditions, the lifespan can vary. However, under normal circumstances, black fiberglass tissue can last for several years without significant degradation, making it a popular choice for applications requiring long-term durability and low maintenance.</p>

- Q: Can black fiberglass tissues be utilized in the creation of decorative elements for outdoor use?

- <p>Yes, black fiberglass tissues can be used to create decorative elements for exteriors. Known for their durability and resistance to weather conditions, fiberglass materials are ideal for outdoor applications. They can be molded into various shapes and designs, offering a modern and sleek aesthetic. However, it's important to ensure that the fiberglass is treated with UV inhibitors to prevent fading and degradation from prolonged sun exposure. Proper installation and maintenance are also crucial to prolong the life and appearance of these decorative elements.</p>

- Q: Is it possible to use black fiberglass tissue as a material for painting?

- <p>Yes, black fiberglass tissue can be used for painting, but it requires specific preparation. The surface needs to be properly sanded and primed to ensure paint adhesion. Fiberglass is a composite material and can be challenging to paint due to its smooth and non-porous nature. Using a primer designed for plastics or fiberglass can help the paint bond better. Additionally, the choice of paint is crucial; acrylic or epoxy-based paints are often recommended for their durability and adhesion properties on fiberglass.</p>

- Q: How does fiberglass facing improve insulation?

- Fiberglass facing improves insulation by providing an additional layer of protection to the insulation material. The facing acts as a barrier, preventing air and moisture from entering or escaping the insulation. This helps to maintain the desired temperature inside the insulated space, as well as preventing the growth of mold or mildew. Additionally, the facing enhances the durability and strength of the insulation, making it more resistant to damage and ensuring its longevity. It also enhances the fire resistance of the insulation, providing an added layer of safety. Overall, the fiberglass facing improves insulation by enhancing its thermal performance, moisture resistance, durability, and safety.

- Q: This question asks for the steps and considerations to properly install black fiberglass tissue to ensure its effectiveness and longevity.

- <p>To install black fiberglass tissue effectively and ensure its durability, follow these steps: 1) Clean the surface to be covered thoroughly to remove any dirt or debris. 2) Cut the fiberglass tissue to the required size, ensuring it fits snugly over the surface. 3) Apply a suitable adhesive, such as epoxy resin, to the surface and fiberglass tissue, following the manufacturer's instructions. 4) Press the fiberglass tissue firmly onto the surface, smoothing out any wrinkles or air bubbles. 5) Apply a protective layer of resin over the tissue to seal and protect it. 6) Allow the adhesive to cure fully as per the manufacturer's recommendations. 7) Regularly inspect and maintain the fiberglass tissue to prevent damage and prolong its lifespan.</p>

- Q: This question asks about the distinctions among various types of glass fiber paper, which are materials made from thin strands of glass.

- <p>Different types of glass fiber paper are distinguished by their composition, manufacturing processes, and applications. E-glass is the most common and is used for general purposes due to its good electrical insulation properties. S-glass, known for its high strength, is used in applications requiring mechanical strength, such as in aircraft and sports equipment. C-glass is resistant to chemical corrosion and is used in environments with harsh chemicals. A-glass, or alumino-borosilicate glass, is used for applications requiring high temperature resistance. Lastly, D-glass is designed for low dielectric applications, making it suitable for electronics. Each type has unique properties that make it suitable for specific industries and applications.</p>

Send your message to us

Fiberglass Facing E-Glass Emulsion Chopped Strand Mat

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 kg

- Supply Capability:

- 1000000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords