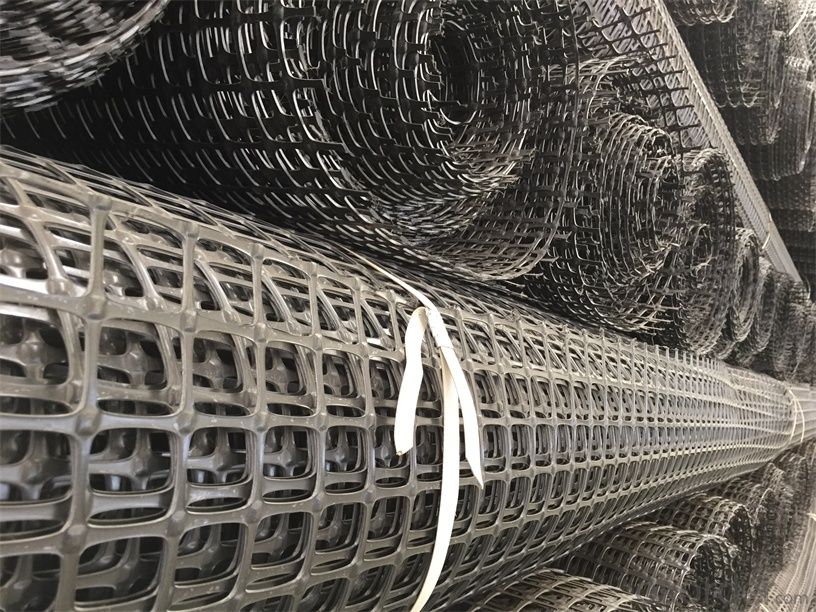

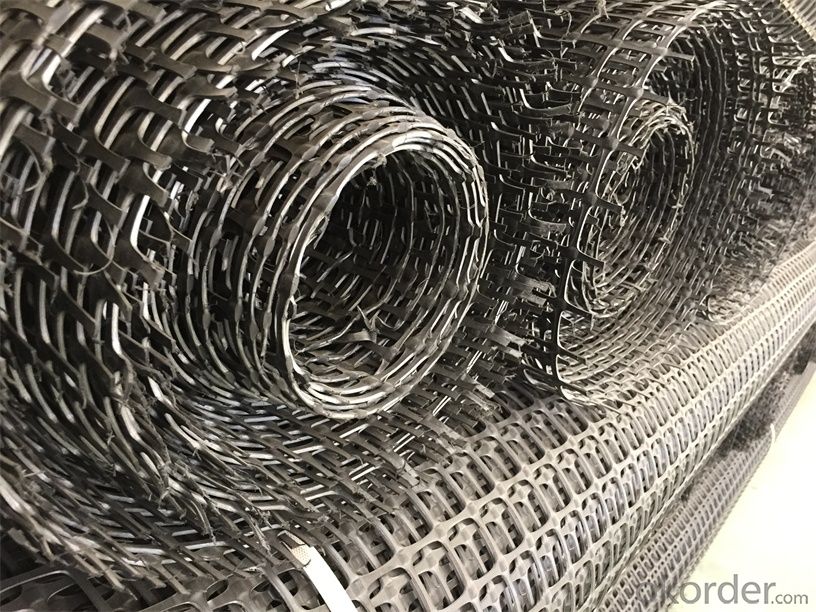

Geogrid Stragrip Sg-150 with High Tensile Strength Warp Knitted

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20000 m²

- Supply Capability:

- 50000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Fiberglass Geogrid Introduction:

Fiberglass geogrid is a kind of planar mesh material using alkali-free fiberglass yarn as base body and then coated with high quality modified asphalt. It is warp knitted with oriental structure which gives full play of yarn strength and improves its mechanical property to make the product high tensile, tearing and creep-resistant. Moreover, the composite property of coating with asphalt makes full protection of the fiberglass matrix and greatly improves its wear and shear resistance. All the advantageous functions make the product have a good performance in pavement strengthening, track cracking and solving difficulties of strengthening the bituminous pavement.

Fiberglass Geogrid Features:

1. Light weight, high tensile strength, high modulus, low elongation and good toughness.

2. Corrosion resistance, no long-term creep, long life span.

3. Good physical and chemical stability and good thermal stability.

4. Resistant to fatigue cracking, high-temperature track and low temperature shrinkage cracking.

5. Delaying and decreasing crack reflection.

Specifications | PET20-20 | PET30-30 | PET40-40 | PET50-50 | PET80-80 | PET100-100 | PET120-120 |

Elongation(%) | 10%~15% | ||||||

Vert Tensile strength(KN/m) | 20 | 30 | 40 | 50 | 80 | 100 | 120 |

Horiz Tensile strength(KN/m) | 20 | 30 | 40 | 50 | 80 | 100 | 120 |

Grid(mm) | 12.5×12.5 20×20 24.5×24.5 | ||||||

Width(m) | 1—6 | ||||||

Fiberglass Geogrid Application:

1. Road surface asphalt overlay construction engineering; Asphalt layers

reinforcement.

2. Converting old cement concrete road into composite road; Restraining

reflection cracking caused by block shrinkage.

3. Road extension; Preventing and controlling the cracking caused by new

and old combination and uneven settlement.

4. Treatment of the conjunction between tunnel and bridge or foundation.

Packaging & Shipping:

FAQ:

1. How to order your geogrid ?

a) Tensile strength in warp & weft direction

b) Grid size

c) Roll Width and length

d) Quantity

2. What is the Payment term?

a) TT

b) LC AT SIGHT

c) cash

d) 30% contact value as deposit ,the blance 70% be paid after received the copy of bl .

3. Delivery time

a) 19-25 days after received your depsit .

4. What is MQQ ?

a) 2500 m2 as MQQ , we can also produce sample for you .

Welcome to send your inquiry to us, and if you have any question, we can also help you.

- Q: How do geogrids improve the load-bearing capacity of foundations?

- Geogrids improve the load-bearing capacity of foundations by providing reinforcement and stability to the soil. These geosynthetic materials are placed within the soil layers and their interlocking geometry creates a more rigid and compact structure. This helps distribute the load evenly across a wider area, reducing the risk of settlement and increasing the overall strength of the foundation.

- Q: Can geogrids be used in stabilization of riverbanks?

- Yes, geogrids can be used in the stabilization of riverbanks. Geogrids are commonly used in civil engineering projects to reinforce soil and prevent erosion. When used in stabilization of riverbanks, geogrids can help retain the soil, provide structural support, and reduce the risk of erosion caused by the river's flow.

- Q: Who knows how much the staggered distance of the lap joint of the geogrid is?

- A grille is made of polypropylene, PVC polymer and thermoplastic or molded by two-dimensional grid or a certain height of the three-dimensional mesh screen, when used as a civil engineering, called geogrid.

- Q: Are geogrids suitable for reinforcing landfill caps?

- Yes, geogrids are suitable for reinforcing landfill caps. Geogrids are commonly used in landfill engineering to enhance the stability and strength of landfill caps. They provide reinforcement and prevent the movement and erosion of soil, thereby increasing the overall efficiency and effectiveness of landfill caps in containing waste materials.

- Q: What are the design considerations for geogrid-reinforced structures?

- Some design considerations for geogrid-reinforced structures include the selection of appropriate geogrid materials, the determination of the required geogrid strength and stiffness, the analysis of soil-geogrid interaction, the assessment of long-term durability, and the consideration of construction and installation techniques. Additionally, factors such as site conditions, loading conditions, and environmental considerations should be taken into account during the design process.

- Q: What is high strength geogrid

- High strength geogrid grille is actually refers to the large geogrid,

- Q: How do geogrids affect soil compaction?

- Geogrids help to improve soil compaction by providing reinforcement and stability to the soil. They distribute the load more evenly, reducing the risk of settlement and improving overall soil strength. Additionally, geogrids enhance the interlocking behavior of soil particles, increasing the soil's resistance to shear forces and minimizing lateral movement.

- Q: Geogrid GSZ 100 50/PP what does it mean

- The rear PP should be the PP solder grid.

- Q: What are the quality control measures for geogrid manufacturing?

- Quality control measures for geogrid manufacturing include: 1. Raw material testing: Ensuring that the materials used in the manufacturing process meet the required specifications and quality standards. 2. Process control: Implementing strict monitoring and control of each stage of the manufacturing process to ensure consistency and adherence to quality standards. 3. Product testing: Conducting rigorous testing of the geogrids at various stages of production to evaluate their mechanical properties, such as tensile strength, elongation, and durability. 4. Statistical process control: Using statistical methods to monitor and control the manufacturing process, identifying any deviations from the desired quality standards and taking appropriate corrective actions. 5. Quality inspections: Conducting regular inspections of the manufacturing facilities and equipment to ensure proper maintenance and calibration, preventing any potential quality issues. 6. Traceability: Implementing a system to track and trace each batch of geogrids manufactured, ensuring accountability and facilitating prompt recall or corrective actions if necessary. 7. Continuous improvement: Regularly reviewing and analyzing quality data, customer feedback, and industry trends to identify areas for improvement and implement corrective and preventive measures. By implementing these quality control measures, geogrid manufacturers can ensure consistent production of high-quality products that meet the required standards and customer expectations.

- Q: What are the properties and characteristics of geogrids?

- Geogrids are synthetic materials, typically made from polymer materials such as polyethylene or polypropylene, that are used in civil engineering and construction projects. These materials possess several important properties and characteristics. Firstly, geogrids have high tensile strength, which allows them to effectively distribute loads and provide structural reinforcement to the soil. They also have excellent resistance to chemical and biological degradation, making them suitable for long-term applications in various environmental conditions. Geogrids are lightweight, flexible, and easy to handle, making installation and transportation more convenient. Additionally, these materials exhibit low elongation and creep characteristics, ensuring long-term stability and performance. Overall, geogrids offer superior soil stabilization, erosion control, and reinforcement properties, making them valuable in a wide range of geotechnical and construction projects.

Send your message to us

Geogrid Stragrip Sg-150 with High Tensile Strength Warp Knitted

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20000 m²

- Supply Capability:

- 50000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords