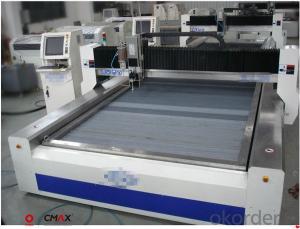

Gear Hobbing Machine with High-precision

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 Set set

- Supply Capability:

- 100 Sets per Month set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Our Gear Hobbing machine obtains a high-precision and high-speed cutting capacity by utilizing a strong main body.

Features

1.Our Hobbing machine obtains a high-precision and high-speed cutting capacity by utilizing a strong main body.

2.The YH200-W has an anti-dust and anti-abrasion table with a long-time fixation rate and high-speed rotation through a dust-proof table design.

3.The spindle has adopted a strong roller bearing structure with a high fixation rate and a great strength. In addition, as there is no thermal deformation or abrasion even under high-speed and powerful cutting, the YH200-W does not need readjusting and is available for high-precision gear processing. The control of the spindle speed follows the CVT (Continuously Variable Transmission) system and can be set to the optimal cutting speed. (The RPM can be set separately for double cutting.)

4.Various attached functions such as jumping, double cutting, automatic cycling of the worm gear, automatic loading, unloading and crowning of processed goods, and an automatic door provide for an optimal automatic production line along with PLC control functionality.

Specifications

| MAX.HOBBING CAPACITY | 200 | |

| MAX.HOBBING CAPACITY OF MODULE | M 6 | |

| MAX.TRAVEL OF HOB SADDLE | 400 | |

| HOB CENTER TO WORK CENTER DISTANCE | 150~350 | |

| TABLE DIAMETER(FACE) | 200 | |

| TABLE THROUGH HOLE | 78 | |

| MAX.HOB DIA×LENGTH | 150 × 180 | |

| MAX.TRAVEL OF HOB SHIFTING | 80 | |

| VARIABLE HOB R.P.M | 60~500 RPM | |

| FEED | LOW | 0.64~4.22 |

| HIGH | 0.93~6.15 | |

| MOTOR | MAIN | 5.5 (4P) |

| RAPID | 1.5 (4P) | |

| COOLANT(CUT) | 250 W | |

| COOLANT(WASHING) | 250 W | |

| LUB.(MACHINE) | 0.4 (4P) | |

| LUB.(SLIDE) | 25 W | |

| HOB SHIFT | 60 W | |

| HYD, PUMP | 1.5 (4P) | |

| OUT SIDE DIMENSION(W×L×H) | MAX. 2065(W) × 3485(L) × 2080(H) | |

| GROSS WEIGHT | APPROX 6000 | |

Technical Environment

The repeated precision of cutting depth is held perfect through the servo motor.

Fine adjustments are available by using an M.P.G. (adjustable down to 0.002mm).

Using bearings around the head spindle and the table spindle has made it possible to have high resistance to thermal deformation and abrasion even under high-speed rotation.

A forced circular oil cooling system was adopted to keep a high fixation rate.

The full splash guided system keeps cutting oil from being scattered, and the oil mist collector helps to prevent environmental pollution. (optional)

The pileup of chips was minimized by installing the washing line separately.

The CVT (Continuously Variable Transmission) of the Hob rotation speed is made possible by an I.G.B.T inverter. (optional)

Standard Accessories

*Hob Arbor(Collar. Sleeve. Nut)---- 1 set

*Change Gear---- 1 set

*Accessory Tools & Box---- 1 set

Optional Accessories

*Hyd. Jig & Fixture

*Chip Conveyor

*Crowning Attachment

*Automatic Door (Air)

*Automatic Hob Shift Equipment

*Worm Gear Cutting Equipment

*Oil Cooling System

*Hob Spindle Variable Speed

*Full Splash Guard

*Auto Loading / Unloading System

*Work Stocker

- Q: Machine Y3150E code meaning

- Y3150E machine in accordance with GB / T8064-1998 "hobbing machine precision test" standard inspection factory.

- Q: Machining machine equipment in general classification

- Standard, general machine tools, generally available in the relevant national standards Model:

- Q: According to the function of the machine and the control shaft to the points, CNC machine tools are divided into several categories

- drilling machining center, it is based on the NC milling machine to increase the capacity of a larger knife and automatic tool changer formed, the workpiece after a clamping, the box parts can be four or even five large Part of the processing process for milling, boring, drilling, expansion, hinge and tapping and other multi-process processing

- Q: What is the classification of machine tools?

- (2) Horizontal CNC lathes Horizontal CNC lathes are divided into CNC horizontal rails Horizontal lathes and CNC tilting rails Horizontal lathes.

- Q: Lathe classification

- Metal cutting machine can be divided into different types according to different classification methods

- Q: What is the best machine tool manufacturers in China

- New machine group, Puyang Beiying, France and Britain, and so on, and your question is too vague, you want the machine is what kind of ah, or how to answer ah.

- Q: What are the manufacturers of machine tools?

- Machine is the machine that makes the machine, also known as the machine tool or machine machine, used to be referred to as machine tools. Generally divided into metal cutting machine tools, forging machine tools and woodworking machine tools. In addition to cutting, there are casting, forging, welding, stamping, extrusion, etc., but those who require high precision and surface roughness requirements of the smaller parts, generally need to be in the processing of mechanical parts, Machine tool with the cutting method for the final processing. Machine tools play a major role in the construction of national economy modernization.

- Q: Which CNC machine does not belong to continuous control CNC machine?

- He not only controls the moving parts from one point to another, but also controls the speed and displacement of each point of the entire process, and the parts are machined into a certain contour.

- Q: I heard that the machine tool processing with a small amount of lubricating oil is better than the cutting fluid, which is now slightly better lubrication which brand

- Our company 26 aluminum extrusion line, with the easy to use.

- Q: The main difference between machine tools and lathes

- Equipment used to make machine parts known as metal cutting machine tools, referred to as machine tools.

1. Manufacturer Overview

| Location | Daegu,South Korea |

| Year Established | 1965 |

| Annual Output Value | |

| Main Markets | South America Southeast Asia Eastern Asia Southern Europe South Asia |

| Company Certifications |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | |

| Export Percentage | 51% - 60% |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b) Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Gear Hobbing Machine with High-precision

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 Set set

- Supply Capability:

- 100 Sets per Month set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches