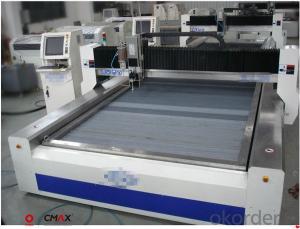

CNC Gear Hobbing Machine with Low price

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 Set set

- Supply Capability:

- 100 Sets per Month set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Equipment of the HERA 200, HERA 350

Radial cutting cycle

Radial tangential cycle

Radial axial cycle

Crowned hobbing

Tapered cutting

Cleated cutting

Single or double cut cycle

Any direction of all the cuts

Intermittent feed

Single indexing

Dwell in/out

Shifts / Synchronising shifts

Prod. data(cutting + overall time, total piece nr.)

Storage option of 99 work pieces, the data of which is directly adopted from the user interface or loaded in this

Standard Unit Specification

*Hob Arbor (1Set : Arbor. Sleeve. Collar)

*Cutting oil device (Coolant Supply Unit)

*Washing device (Coolant Washing Unit)

*Hydraulic tank (Hyd. Pump Unit / Tank)

*Automatic lubricating pump (Intermittent Lub Tank)

*The whole cover (Full Splash Guard)

*C.N.C controller (SINUMERIK 840D / SIEMENS GERMANY)

*Operating Manual (Maintenance / Operating Manual)

*Standard Tools & Box

Optional Unit

Hyd Fixture Device

Chip Conveyor

Auto Draw Bar Attachment

Auto Door (Air)

Oil Mist Collector

Oil Chiler

Loading / Unloading System

Stocker

| Machine table diameter | φ 320 | ||

| Table bore diameter | φ 82 | ||

| Hob speed | rpm | min-max | 20~500/40~1000 |

| Machine table speed | rpm | max | 150 |

| Cutter spindle drive power | 39Nm | ||

| Radial feed rate | /min | max | 6000 |

| Vertical feed rate | /min | max | 6000 |

| Tangential feed rate | /min | 1500 | |

| Total input power | 35KVA | ||

| Total machine weight | ton | 9.5 | |

| Space requirementy | (W×L×H) | 2700 × 3100 × 2800 | |

- Q: How many kinds of CNC machine tools? Can you completely replace the bed?

- For small parts, not complicated with no use of CNC equipment, CNC equipment, procurement costs, operating costs, the use of high cost.

- Q: What does the machine code "CM6132" mean?

- C indicates the type of lathe type (ie, lathe) "M" indicates that the machine common characteristic code (ie precision lathe) "6" indicates the machine group code (ie floor or ordinary lathe group) "1"

- Q: What does the generic machine model contain?

- Precision machine tools: including grinding machines, gear machining machines, threading machines and other precision machine tools.

- Q: How to press heavy. Medium, light classification of various types of machine tools

- The machine tool is divided into 11 categories: lathe, drilling machine, boring machine, grinding machine, gear machine, threading machine, milling machine, planing machine, drawing machine, drawing machine

- Q: What is the classification of machine tools?

- This machine is mainly used for processing large radial size, axial size is relatively small large complex parts.

- Q: CNC machine tools are divided into several categories, respectively, what?

- Metal forming CNC machine tools; such machine tools, including CNC bending machines, CNC combination punch, CNC bending machine, CNC rotary head presses.

- Q: Can ordinary lathe work gear?

- Can not be processed only by the wheel of the large, that is, the size of the top circle, and then can be processed with the gear with the hole Oh gear processing is generally in the hobbing machine, milling machine and other processing, to know the whole process of gear is not

- Q: Gear processing methods and processing principles there are several

- (Tooth surface), is the ideal involute, the processing of high precision, common with, hobbing, shaving teeth, shaving teeth (belonging to finishing), the cutting gear,

- Q: Gleason p300es what machine is

- Most grinding machines use high-speed rotating grinding wheels for grinding, and few are used for grinding of abrasive, abrasive and other abrasives and free abrasives such as honing machines, ultra-finishing machines, abrasive grinding machines, grinding machines and polishing

- Q: The main difference between machine tools and lathes

- Measuring the quality of a machine is a multifaceted, but mainly requires a good process, serialization, generalization, high degree of standardization, simple structure, light weight, reliable, high productivity.

1. Manufacturer Overview

| Location | Daegu,South Korea |

| Year Established | 1965 |

| Annual Output Value | |

| Main Markets | South America Southeast Asia Eastern Asia Southern Europe South Asia |

| Company Certifications |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | |

| Export Percentage | 51% - 60% |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b) Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

CNC Gear Hobbing Machine with Low price

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 Set set

- Supply Capability:

- 100 Sets per Month set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches