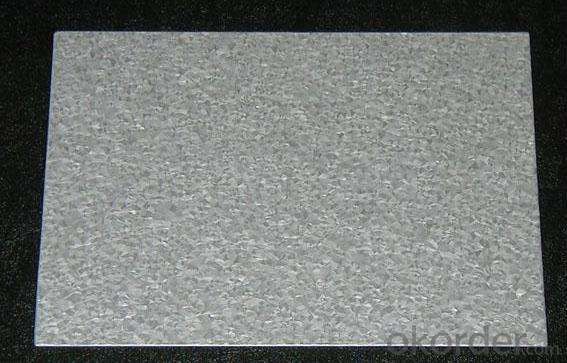

Gavalume Mg steel coils

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Coating ingredients respectively according to the weight ratio from 55% of the aluminum and 43.4% of zinc, 1.6% of silicon composition.

Quick Details

| Standard: | Grade: | Thickness: | |||

| Place of Origin: | Brand Name: | Type: | |||

| Technique: | Surface Treatment: | Application: | |||

| Width: | Length: | Coil Weight: | |||

| AZ Coating: | Technology: | Post-processing: |

Packaging & Delivery

| Packaging Detail: | Standard export package or as per client's requirements. |

| Delivery Detail: | Within 15-20 days after we receive deposit or L/C at sight. |

Specifications

Galvalume Coil

1.Grade:DX51D-AZ, DX53D-AZ, SGLCC, etc

2.Thickness:0.35-2.3mm

3.Width:600-1270mm

4.ID:508mm

- Q: describe the benifits and disadvantages of the using steel as a material for fasteners

- Relatively cheap, strong, and non-toxic. For Carbon Steel alloys rust and corrosion are problems. For stainless alloys, cost becomes the problem [and corrosion is not eliminated]

- Q: Are steel coils affected by magnetic fields?

- Yes, steel coils can be affected by magnetic fields. Steel is a ferromagnetic material, which means it can be magnetized and attracted to magnetic fields. When exposed to a magnetic field, the steel coils can have their magnetic properties influenced, leading to changes in their behavior and potentially affecting their performance.

- Q: How much does a steel coil weigh?

- The weight of a steel coil can vary depending on its size, thickness, and type of steel used. Generally, a standard steel coil can weigh anywhere from a few hundred pounds to several thousand pounds.

- Q: What are the dimensions of steel coils used in the power generation industry?

- The specific application and requirements determine the varying dimensions of steel coils used in the power generation industry. Generally, there is a wide range of sizes and thicknesses available for power generation steel coils. For power generation purposes, the width of steel coils can range from a few inches to several feet, depending on the intended equipment or machinery. These coils are specifically designed to fit manufacturing processes or components within power generation systems. The thickness of steel coils used in power generation can vary greatly. Thicker coils are commonly used for heavy-duty applications that require increased strength and durability. On the other hand, thinner coils may be suitable for less demanding tasks or when reducing weight is a priority. Furthermore, the weight of steel coils for power generation can vary based on their dimensions and the specific steel material used. Consideration of weight is crucial during transportation, installation, and handling of the coils. It is worth noting that manufacturers in the power generation industry can customize the dimensions of steel coils to meet specific project requirements. They work closely with power generation companies to understand their needs and offer tailored solutions that meet their dimensional specifications.

- Q: How do steel coils contribute to strength and stability in structures?

- Steel coils are vital components in numerous structures due to their significant impact on strength and stability. The exceptional strength of steel itself makes it renowned, as it can resist large amounts of tension without breaking or deforming. When steel is shaped into coils, its strength is further enhanced by evenly distributing the load across the entire structure. This even distribution of force prevents localized stress concentrations, enabling the structure to withstand heavy loads and external pressures more effectively. Furthermore, steel coils provide stability to structures by offering rigidity and resistance against deformation. Steel is known for its stiffness, preventing excessive flexing or bending under loads. The tightly wound coils create a robust and compact structure that can efficiently resist dynamic forces like wind, earthquakes, or vibrations. This resistance to deformation minimizes potential damage, ensuring the structure's stability and integrity. Moreover, steel coils also contribute to the durability and longevity of structures. Steel exhibits remarkable durability, being highly resistant to corrosion, rust, and deterioration over time. This longevity ensures that structures built with steel coils can remain strong and stable for extended periods, requiring minimal maintenance or repairs. Additionally, steel coils offer versatility in design and construction. The ability to shape steel into various coil sizes and configurations allows for customization based on specific structural requirements. Architects and engineers can utilize steel coils to create complex structures while maintaining their strength and stability. This versatility allows for innovative and efficient design solutions, making steel coils the preferred choice in many construction projects. In conclusion, steel coils play a crucial role in enhancing the strength and stability of structures. The inherent strength of steel, combined with the unique design of coils, provides structures with the necessary rigidity, resistance to deformation, and durability. Additionally, the versatility of steel coils allows for customization and innovative design solutions. Overall, steel coils significantly contribute to the overall integrity and longevity of structures, making them an essential component in the construction industry.

- Q: I noticed that Jimmy Page finger picked on a steel acoustic guitar on quite a few tracks like Stairway to heaven and other ones and I was wondering how did he do it? I know it is more difficult to finger pick on a steel acoustic because of the rougher steel strings and higher tensions so I was wondering do they make specific strings that allow for fingerstyle playing? Also Randy Rhoads finger picked a steel acoustic on Dee along with a Classical guitar.

- First okorder /... In truth their are many, many players who finger pick acoustic guitars, once you get the hang of the various picking patterns it's not extremely difficult to do. There aren't really any specific strings that are required to finger pick. It will mostly come down to the players preference and the type of music they are doing. It is actually more difficult to finger pick an electric guitar since you have less room between the strings and the pickup so you will find that a lot of times you will hit the pickup with the metal finger pick which can be a bit disturbing but practice helps. Pat SImmons of the Doobie Brothers uses finger picks on a Gibson ES335 all the time.

- Q: How are steel coils used in the production of shipbuilding components?

- Steel coils are used in the production of shipbuilding components as they provide a strong and durable material for constructing various parts of ships such as hulls, decks, and bulkheads. These coils are processed and shaped into required forms, ensuring the structural integrity and stability of the ship.

- Q: What is the maximum diameter of a steel coil?

- The maximum diameter of a steel coil can vary depending on the specific manufacturing process and equipment used. However, in general, the maximum diameter of a steel coil can range from a few inches to several feet.

- Q: is surgical steel or sterling silver belly button rings better for you? surgical is really cheap so its sketch and i justt dont want it to mess up

- Sterling silver is not meant for extended wear in body piercings, and should NEVER be worn in fresh or unhealed piercings - the silver will tarnish, and the tarnish can be deposited into your skin which causes it to turn gray or black. Silver can also cause allergic reactions for those who have nickel allergies. So it's okay to wear for a special occasion in a healed piercing, but has lots of nasty side effects if left in too long. As for the surgical steel: not all SS body jewelry is created equal! Lots of cheap steel body jewelry is made out of 316L Stainless steel, which is the minimum requirement for steel worn in healing/fresh piercings. Some people can wear this type of steel, but it can (and does) irritate and cause allergic reactions for others. Personally, I will only wear 316LVM ASTM F-138 Implant Grade Steel, which is the same type of material that doctors use when they put pins and plates in your body during surgery. It is the highest quality steel you can get, and will usually cost a bit more, but as someone with sensitive skin I am not willing to risk getting an allergic reaction from sub-par jewelry. Also, implant-grade jewelry is most often INTERNALLY-THREADED, which means that the threads are concealed inside the jewelry and do not come in contact with your skin. EXTERNALLY-THREADED jewelry has the threads on the outside, and inserting it into your piercings is pretty much the equivalent of dragging a screw through your navel. Whatever grade of steel you decide to go with, make sure the threads are on the inside!

- Q: Is there alloys in low carbon steel or non

- Hello, okorder Hoping this can help you. :-)

Send your message to us

Gavalume Mg steel coils

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords