Gate Valve DIN Double Flange Type in Ductile Iron

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 50 pc

- Supply Capability:

- 200 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Structure of Gate Valve Description:

A gate valve, also known as a sluice valve, is a valve that opens by lifting a round or rectangular gate/wedge out of the path of the fluid. The distinct feature of a gate valve is the sealing surfaces between the gate and seats are planar, so gate valves are often used when a straight-line flow of fluid and minimum restriction is desired. The gate faces can form a wedge shape or they can be parallel. Gate valves are primarily used to permit or prevent the flow of liquids, but typical gate valves shouldn't be used for regulating flow, unless they are specifically designed for that purpose. Because of their ability to cut through liquids, gate valves are often used in the petroleum industry. For extremely thick fluids, a specialty valve often known as a knife valve is used to cut through the liquid. On opening the gate valve, the flow path is enlarged in a highly nonlinear manner with respect to percent of opening. This means that flow rate does not change evenly with stem travel. Also, a partially open gate disk tends to vibrate from the fluid flow. Most of the flow change occurs near shutoff with a relatively high fluid velocity causing disk and seat wear and eventual leakage if used to regulate flow. Typical gate valves are designed to be fully opened or closed.When fully open, the typical gate valve has no obstruction in the flow path, resulting in very low friction loss.

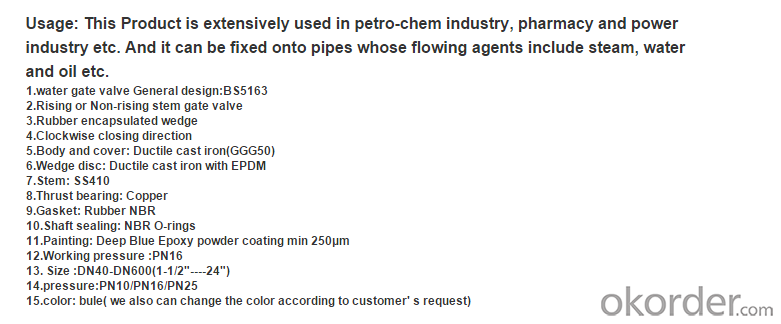

2. Main Features of the Gate Valve:

• Valve body cavity using non-toxic epoxy resin,both inside and outside flashboard completely is coated with rubber

• Free of water pollution

• High manufacturing accuracy

• High strength

• Environmental protection and energy saving

• Good visual effect

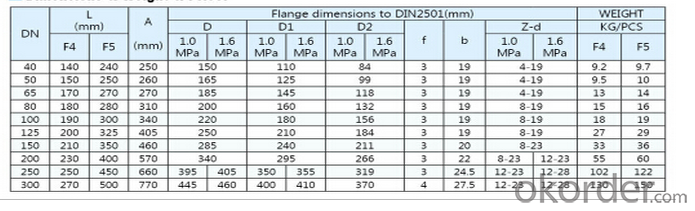

3.Gate valve Specification

4. Images

5.FAQ

1) What's are the characteristics of gate valve?

The distinct feature of a gate valve is the sealing surfaces between the gate and seats are planar, so gate valves are often used when a straight-line flow of fluid and minimum restriction is desired. The gate faces can form a wedge shape or they can be parallel.

2) What is the work principle of gate valve ?

The gate faces can form a wedge shape or they can be parallel. Gate valves are primarily used to permit or prevent the flow of liquids, but typical gate valves shouldn't be used for regulating flow, unless they are specifically designed for that purpose. Because of their ability to cut through liquids, gate valves are often used in the petroleum industry.

3) What is the structure?

Bonnets provide leakproof closure for the valve body. Gate valves may have a screw-in, union, or bolted bonnet. Screw-in bonnet is the simplest, offering a durable, pressure-tight seal. Union bonnet is suitable for applications requiring frequent inspection and cleaning. It also gives the body added strength. Bolted bonnet is used for larger valves and higher pressure applications.

- Q: What type of flange does it fit with the gate valve?

- According to the welding plate flange, flange material selection of piping material.

- Q: What is the difference between the model z81x-16q and z81x-16c of the groove gate valve?

- Not 16qIs 16p, the former body is stainless steel, and the latter body is carbon steel

- Q: What does gate valve Z41H-40 mean?

- 40 kg flanged cast steel gate valve;Flanged gate valve, 40 pressure

- Q: What does Z941H-25DN250 mean by electric gate valve (excluding electric equipment)?

- Cast steel flanged gate valve 25 pressure bore 250

- Q: What is the difference between an elastic gate valve and a rigid gate?

- One is cast iron, intermediate rubber gate, one is cast steel, and the other is steel flashboard,

- Q: What is the difference between gate valve Z41T and Z45T?

- Z41T is a dark pole gate valve, and Z45T is a plain rod gate valve,

- Q: What's the difference between a soft seal gate valve and a hard sealed gate valve?

- The difference is that the form of the gate seal surface is different.General gate valves are generally leaking, easy to rust and other phenomena. Soft sealing gate valve (elastic seat sealing gate valve), gate material for cast iron lining rubber, overcome the shortcomings of the general gate valve, such as poor sealing, elastic fatigue, easy to rust, etc.. Soft sealing gate valve is a new product of the traditional gate valve.

- Q: What is the size and length of the DN80 gate valve? 10 kg and 16 kg, respectively?

- Valve structure length standards are PN16, short series for 203mm, long series for 280mm, flange size by PN16.

- Q: What is the difference between gate valve 41h-16c and 41w-16p?

- According to the provisions of the JB/T 308-2004 valve type programming method:H== sealing surface material: Cr13 stainless steelC== body material: carbon steelW== sealing surface material: body, that is, with the same material bodyP== body material: chrome nickel stainless steel

- Q: What are the standards for the execution of cast iron dark pole gate valves?

- They are also standard in the production of cast iron dark rod gate valves:Design and manufacture: as per GB/T12234-89 regulationsLength of structure: as specified by GB/T12221-89Flange dimensions: as specified in JB79 GB/T9112-9131Inspection and test: as specified in JB/T9092-99 GB/T13927-92Drive mode: manual, electric, gear drive

Send your message to us

Gate Valve DIN Double Flange Type in Ductile Iron

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 50 pc

- Supply Capability:

- 200 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords