Gardening Seed Tray /Plug Tray /Nursery Tray 32 Cells

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3000 pc

- Supply Capability:

- 2000000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

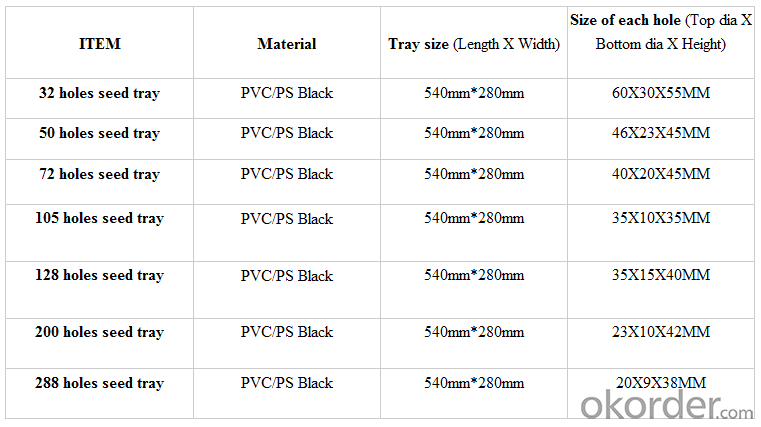

Specification of Plug Trays HIPS Made Plastic Plug Tray for Greenhouse (Growing and Seedling):

Features of Plug Trays HIPS Made Plastic Plug Tray for Greenhouse (Growing and Seedling):

· Material: HIPS

· Thickness: 0.5mm-1.5mm, Standard:1mm

· Weight: 80g(±5)g-230g(±5)g, Standard weight:155g(±5)g

· Size: length:490mm-540mm, width:190mm-345mm,depth:25mm-150mm

· Standard:540mmX280mm

· Cell count: 18-512

· Package: In Carton

· Warrenty: 8-10 times

Packaging & Delivery

Packing Detail: export standard carton or large bags

Delivery time: 4 million per momth after receipt of deposit

Advantage:

Waterproof, UV-resistant, extrusion-resistant

Easy carry for young seeding plant and grow

Service:

1. Quick, efficient and professional response within 24 hours, 14 hours online services

2. 10 years manufacturing and exporting experience in agriculture field.

3. Technical support and solution by chief engineer.

4. Strict quality control system & team, high reputation in the market.

5. Full range of irrigation products for choice

6. OEM/ODM services

7. Accept sample order before Mass Order

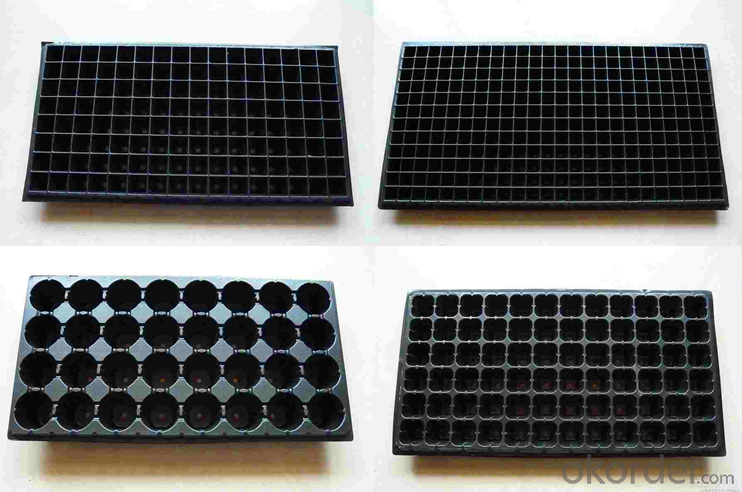

Picture of Plug Trays HIPS Made Plastic Plug Tray for Greenhouse (Growing and Seedling):

FAQ of Plug Trays HIPS Made Plastic Plug Tray for Greenhouse (Growing and Seedling):

Q: 1.How long is the production time?

A: Usually one to two weeks.

Q: 2.How is the seed tray being packaged?

A: They can be packaged in carton or pallets. Carton size is 1375px*725px*1250px.

Q:3.How many times can the seed tray be used?

A: Under the same environment, it is decided by the thickness. Usually 0.6mm thickness can be used for 1 or 2 times.

1.0 thickness can be used for 3-4 times. 1.5 thickness can be used for 8-10 times.

- Q: i am making vampire fangs so I need a plastic that i can mold, any ideas?

- plastic bags trust me lol

- Q: I need to buy plastic model cement for a plastic model but don't know where in TORONTO. I bought something that was Elmers that said cement on it and said it worked for plastics, i tried it and it turned out to be like crap wouldnt even glue after like 1000 hours. I just need a glue that works well and holds strong. We use Testors glue at school and its excellent but i dont know where i can buy it from? I also heard of super glue being good, please tell me a good kind and whereeeee

- Super glue, aka, Crazy glue, aka Hot Stuff, is good. Any hobby shop should have it.

- Q: How long does it take for ground cover to establish and fill in?

- The time it takes for ground cover to establish and fill in can vary depending on the specific type of ground cover and the growing conditions. However, on average, it typically takes about 1 to 2 growing seasons for ground cover to fully establish and fill in.

- Q: I have off-white pearls which needs to be recolored into maroon / burgundy.1. I tried with nail polish but it looks ugly as it is uneven.2. I also tried using fabric dye and glass paint, dissolved in water and keeping pearls in it overnight. I feel the second method is done incorrectly.

- How To Dye Plastic

- Q: How and what do you use to join two peices of plastic (specifically abs) using molecular bonding?

- The only plastics which truly bond molecularly are two part resins like epoxys or thermosetting resins which cure when heated. ABS plastics start as monomers and poylmerize into their final form. Because ABS plastics are based on Styrene, aromatic solvents such as benzene or toluene can be used to bond them together. This is principally how model glue is used to bond polystyrene plastic models.

- Q: What is the best ground cover for a modern urban rooftop garden?

- Sedums and succulents are considered the best ground cover options for modern urban rooftop gardens. They are low-maintenance, drought-tolerant, and provide a variety of textures and colors. Additionally, their shallow root systems help to prevent water leakage and erosion, making them ideal for rooftop environments.

- Q: How do agricultural plastic products help with precision planting?

- Agricultural plastic products aid in precision planting by providing advanced technology and tools that help farmers optimize their planting practices. For instance, plastic mulch films help control soil temperature and moisture, creating optimal growing conditions for seeds. Additionally, plastic seedling trays and pots facilitate uniform seedling growth and transplanting, ensuring consistent spacing and placement. These plastic products enhance precision in planting, leading to higher crop yields and improved overall agricultural productivity.

- Q: Can nursery trays be used for orchid propagation?

- Yes, nursery trays can be used for orchid propagation. These trays provide a suitable environment for orchid seeds or cuttings to germinate and grow. The trays typically have compartments or cells that allow for proper spacing and organization of the orchid plants. Additionally, the trays are designed to retain moisture and provide drainage, which is important for orchid propagation.

- Q: Are there any ground cover plants that are deer-resistant?

- Yes, there are several ground cover plants that are known to be deer-resistant. Some popular options include creeping thyme, lamb's ear, pachysandra, and vinca minor. However, it's important to note that no plant can be completely deer-proof, as deer preferences may vary and they may occasionally sample any plant.

- Q: Can agricultural plastic products be used in rooftop greenhouses?

- Yes, agricultural plastic products can be used in rooftop greenhouses. These plastic products, such as greenhouse films and covers, are commonly used to cover the structure of greenhouses to create a controlled environment for plant growth. They provide insulation, regulate temperature and humidity, and protect crops from external elements. Therefore, utilizing agricultural plastic products in rooftop greenhouses can help optimize growing conditions and enhance productivity in urban farming.

Send your message to us

Gardening Seed Tray /Plug Tray /Nursery Tray 32 Cells

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3000 pc

- Supply Capability:

- 2000000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords