Tap-Out Cone Furnace Thermal Insulation Ceramic Fiber Block Module

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 1000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

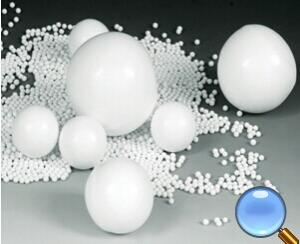

Refractory ceramic fiber module is a new refractory lining product in order for simplifying and speeding up the furnace construction and improving the lining integrity. The product,pure white, normal size, can be directly fixed on the anchor bolt of industrial furnace steel sheet, with a good fireproof and thermal insulation, which increase the furnace refractory insulation integrity and improve the furnace lining technology. Its classification temperature (From 1050°Cto 1600°C).

1. Excellent chemical stability

2. Excellent thermal stability

3. Excellent flexibility, the module is in pre-compression state, after the lining masonry

4. The Expansion of modules enable seamless lining,fiber lining can be compensated to

improve

5. Insulation performance of Fiber lining, and the overall performance is good

6. Excellent thermal stability and thermal shock resistance

7. Ceramic fiber module can be installed quickly, and anchors set in the wall lining ,

which can lower the requiement of anchor material

1. Furnace lining and insulation of furnace in Petrochemical industry

2. Furnace lining and insulation of furnace in Metallurgical industry

3. Furnace lining and insulation of furnace in Ceramics, glass and other builfinh

materials industry

4. Furnace lining and insulation of heat treatment furnace in heat treatment circle

5. other industrial furnace lining

Type | Common | Standard | Zirconium | |

Classification temperature (°C) | 1260 | 1260 | 1400 | |

Shrinkage on heating (%) | 950°C×24h≤-3 | 1000°C×24h≤-3 | 1350×24h≤-3 | |

Thermal conductivity by mean tem. (W/m.k) (200kg/m3) | 200°C | 0.050~0.060 | ||

400°C | 0.095~0.120 | |||

600°C | 0.160~0.195 | |||

Density (kg/m3) | 200 | |||

Size (mm) | 300 × 300 × 200,300×300×250,300 × 300 × 300 | |||

Package | carton | |||

Certificate | ISO9001-2000; ISO14001-1996 | |||

FAQ

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Send your message to us

Tap-Out Cone Furnace Thermal Insulation Ceramic Fiber Block Module

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 1000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords