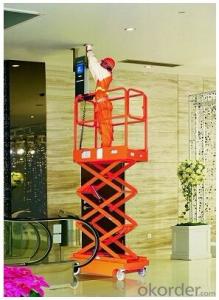

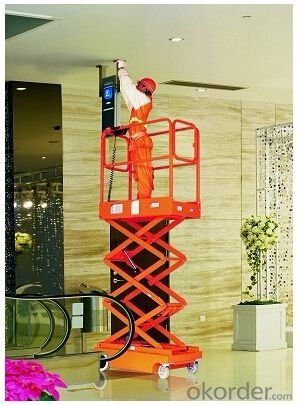

Full Electric Aerial Work Platform Mode III-JCPT3.0

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

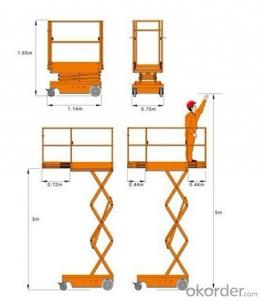

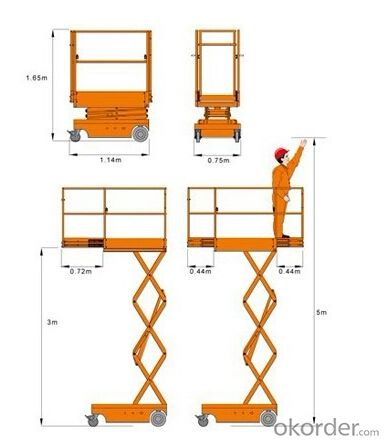

Model | unit | JCPT3.0(III) |

Safe working load | kg | 240 |

Maximum working height | m | 5 |

Maximum platform height | m | 3 |

Overall length | m | 1.18 |

Overall width | m | 0.76 |

Overall height | m | 1.82 |

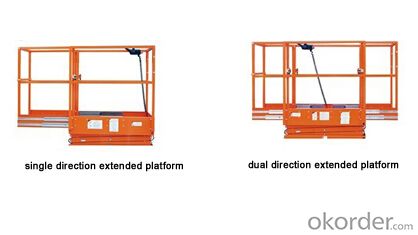

Working platform size | m | 1.17x0.60 |

Minimum ground clearance | m | 0.06 |

Wheel base | m | 0.99 |

Minimum turning radius (inner wheel/ outer wheel) | m | 0 |

Drive motor | kw | Φ2x24VDc/0.4 |

Lifting motor | kw | 24VDC/0.8 |

Driving speed (furling state) | km/h | 4 |

Lifting state | km/h | 0.8 |

Lifting/ descending speed | sec | 28/41 |

Accumulator | Ah | 2x12V/95 |

Charger | A | 24V/12 |

Maximum gradeability | % | 25 |

Maximum working slope | º | 2 |

Driving wheel | m | 230x80 |

Front wheel | in | 6 |

Overall weight | kg | 495 |

Standard Configuration

Can bus line intelligent controller

Proportional controller

Charge lamp

Strut bar for safe overhaul

Low voltage alarm

Emergency descending button

Charge protection

Controller overtemperature protection

4x2 drive

Overload limit

- Q: Does the fixed hydraulic platform need to submit to the specification requirement

- Lift platform, mobile elevators, cargo-lifts equipment, such as the regulations of the state, load is larger than 500 kg of belong to special equipment, is the need in the local quality supervision of special equipment inspection. First, look at the equipment capacity is over 500 kg, then you should go to the local quality inspection of special equipment department to put on record, first need information: including manufacturer's business license, tax registration certificate, organization code certificate, production license of special equipment, special equipment installation and maintenance license, there are different from region to region, it's best to make a phone call to prepare the material.

- Q: There is no elevator on the 7th floor of the home to install a lift or lift

- What do you want to do? Can you agree to install these things? These later additions can only be set outside the building, affecting the fire channel.

- Q: What is the difference between elevator and elevator

- It's the same, but everyone's understanding is different.I hope my answer will help you.

- Q: How about customizing a tatami mat?

- However, the tatami mat is no longer a problem. In a small room decorate a lifting platform tatami, not only improve the utilization rate of the space of the room to receive and we have guests home, tatami is lifting platform rises is a piece of tea table; Descend, and the tatami of the ground to be an organic whole, spread the mat of above a mat of a mat of a mat of a kind of a very beautiful bed. This can not only be used to make tea room, room, study, also can be used as a child's activity place, a room can use more.

- Q: What happened to the rise and fall

- Replace when necessary. Indicator, press the up button, motor rotation and lifting platform does not rise inspection or greater power contact, inverted power supply after the motor, it can be power supply is correct.

- Q: Can the stepping motor drive the hydraulic platform?

- Why do you want to use a step motor? You can put a limit on the platform. If you step into the motor, you don't know if it's a linear relationship

- Q: Operation and attention of electric elevating platform car?

- When the working pressure of the platform is too high or the noise is abnormal, the inspection should be stopped immediately so as not to seriously damage the platform. For general failures, see (troubleshooting and troubleshooting); G, the wind should not be greater than 5 when used, and the machine should not be used in thunderstorm. Note: A, non-electric professional personnel should not disassemble the electrical appliances at will, in case of electric shock or mistake. B: the platform should be hoisted on the platform when the platform is being repaired under the platform. In case the platform suddenly drops, causing casualties;

- Q: The purpose of the rail elevator

- The product structure is strong, the load is large, the lift is stable, the installation maintenance is simple and convenient, is the economical and practical low floor space to replace the elevator's ideal cargo transport equipment. According to the installation environment and use requirements of lifting platform, choose different optional configuration, can achieve better effect, the use of this product is mainly used in chemical, high temperature and high pressure, power plant, the nuclear industry base, such as explosive explosion protection enterprise.

- Q: Diablo ii flame volcanic mission will not be able to jump

- Instead of letting you jump on the platform, let you jump across the plank on the side wall of the platform, which is used upstairs. Just go to the opposite side.

- Q: Safety operation of hydraulic platform

- 4, rise and fall: press the "rise" button, start the motor, the motor spin, the hydraulic system work, the oil cylinder protruding, the platform rises. Stay up to work the required height, "stop" button, the motor stop lifting platform, can work, if not in accordance with the "stop" button, the platform to calibrate height be 8 meters (native) trip switch, platform in height. At the end of the work, press the "drop" button, the solenoid valve action, when the oil cylinder is turned on, the platform is lowered by itself. During the use of hydraulic platform, it is strictly forbidden to overload (the unit load is 300kg), and the operator on the platform will not be moved during the descent. When moving or traction hydraulic platform, the supporting leg should be collected and the platform will be lowered to the lowest position. 7, when platform malfunction cannot work normally, should be promptly cut off the power supply for repair, it is strictly prohibited to equipment to work, in spite of non-professional workers do not remove the hydraulic components and electrical components. Do not use the machine in an unstable condition on the ground. Please do not raise the platform without the platform, the outside legs are not adjusted, the platform is flat and the ground is unstable.

Send your message to us

Full Electric Aerial Work Platform Mode III-JCPT3.0

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords