FRP Filament Winding Machine for Large Scale in High Quality of New Design

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 22 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

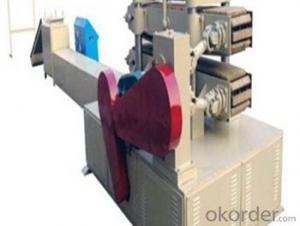

FRP Filament Winding Machine for Large Scale in High Quality of New Design

Product Description:

This set of machine is a professional yarn drawing line, which is mainly used for producing PP, net

yarn, and also can be used for processing other plastic yarns via corresponding adjustment.

This line consists of extruder, cool water tank, the first stretching device, hot water tank, the second

stretching device and coiling machine. The matching devices for production process are complete, so it

can continuously finish the whole procedures from putting material to coil yarn onto bobbins.

Product Features:

1.High precision winding pattern

2.High productivity and low energy consumption

3.Simple installation and maintenance

4.Industrial computer control, easy in operation

Product Parameter:

Name | FRP Filament Winding Machine for Large Scale in High Quality of New Design |

Brand | CMAX |

Weight | 9T |

Dimension(L*W*H) | 11000*3500*2200mm |

Power | 55KW |

Voltage | 440V/220V |

Product Type | FRP Machinery |

Certification | ISO9001:2008 |

Appilication | Sheet |

Raw material | Fiber Reinforced Plastic |

Place of Origin | Hebei, China (Mainland) |

Color | Blue |

Warranty | One Year |

Time of Delivery | 30-45 days |

Product Pictures:

Our Service:

(1)Installation Services

Installation Services are available with all new machine purchases. We will provide the technical know-how for your operation smooth transition and support for installing, debugging, operation of the machine, it will indicate you how to use this machine well.

(2)Clients Training Services

We can train your staff to use your equipment systems properly. It means that we offer Customers Training, teaching how to use the systems most efficiently and safely as well as how to maintain optimal operational productivity.

(3)Good After-Sales Service

We offer the Preventative Maintenance and After Sales Service. We offer comprehensive maintenance options to prevent equipment issues before they become problems. Also we offer one year guarantee period.

FAQ:

1.Q: Can we send sample for customizing the machine?

A: No problem, you can send us samples, and our engineer will recommend and customize the

machine according to your product and other demand.

2.Q: Can we go to your factory discussing more detail and checking the quality of the machine?

A: Yes, no problem, welcome to our factory and we will do our best to help you.

3.Q: Can we inspect the machine before delivery?

A: Yes, you can come and inspect the delivery. If you can not come, we have specialized engineer

team to test the machine and inspect the delivery. We guarantee that you can receive a totally good

machine.

4.Q: If we have problem on machine or production, can you help us?

A: Yes, no problem.We offer the Preventative Maintenance and After Sales Service. We test the

machine before delivery. We offer comprehensive maintenance options to prevent equipment issues

before they become problems. Also we offer one year guarantee period. If there is problem in using,

you can tell us. Our engineer team will do best to help you solve the problem. Our engineers can go to

your factory and help you solve the problem. We provide longlife service for the machine.

- Q: The next 5 to 10 years, small workshops waste plastics processing prospects for development?

- China's plastic machinery industry production enterprises are large, most enterprises seriously deviate from the economic scale, production equipment backward, technical progress difficult situation is still serious. But some enterprises grasp the trend of market demand and technical development, through technical transformation effectively seize market opportunities, develop economic indicators of economic scale backbone enterprises begun to take place before the sort of product sales enterprises accounted for about twice the total domestic plastic machinery sales. So far, China's plastic machinery products are still medium, small as the mainstream, production has been in the world for many years.In 2012, China exported 69297 sets of plastic machinery, with a total amount of 1 billion 618 million 868 thousand US dollars, with an increase of 10.5% over the same period of last year, and the growth rate fell by 17.9% compared with 2011. Imports of plastic machinery 10482 units, total 2 billion 126 million 350 thousand U. S. dollars, the number of imports and the amount of year-on-year decrease, of which the amount of imports decreased by 2.4%. The year 2012 presses trade deficit of $507 million 485 thousand, compared with 2011 deficit significantly reduced.In 2013 the number of China machinery import 10052 units, the amount of imports of about $1 billion 820 million, and last year fell by 4% and 15%; exports, total exports in 2013 China machine 135213 units, the export amount of approximately $1 billion 720 million, an increase of 94% and 7% respectively.In the first half of 2014, China imported 4156 injection molding machines, an increase of 63%, and imports amounted to 398 million 650 thousand U. s.dollars, an increase of 18%.

- Q: Are the fragrance of poisonous substances poisonous in plastic products?

- Poisonous, smelling, and dying so fast, so many people with mechanical hand out, we repair the manufacture of mechanical hand

- Q: Plastic blank in the gear hobbing machine processing, hob and workpiece is not to heat, then plastic is not easy to stick on the machine body.Just want to know the plastic gear processing technology is how, and ordinary steel gear processing technology difference where?.The more detailed, the better. Thank you

- LZ, Hello, about plastic gear processing and technology, I suggest you go to China Machinery CAD forum to see, I believe it will help you,

- Q: Is it gear oil or general oil?Inside the old oil is relatively thin, the new gear oil is relatively thick. Can you add?.Please point out.Should we add "ordinary gear oil" or "hyperbolic"?

- Gear oil should be added, and the old one may be flooded or originally not gear oil.Regular is ok.

- Q: What are the processes and machines used in the manufacture of plastic products?,

- Processing methods are: injection molding, extrusion, blow molding, blister and so on. Injection molding can be used to produce more complex shapes, such as TV housings. It is the plastic particles in the pre heating tube, and then through the screw under pressure, the melting of raw materials into the mold, cooling molding, the product has been made. Is prepared by continuous extrusion screw drive, which in the feed pipe (commonly known as the barrel) heating plasticization, and then squeeze the stereotypes in the mold, the desired shape, such as plastic buckle, pipes etc.. Blow molding and extrusion are somewhat similar, except that they are placed in compressed air to obtain shapes, such as plastic films, plastic bottles, etc.. Blister is relatively simple, it first made of plastic sheets, baking oven, and then placed in the mold, through the negative pressure to the sheet and mold close to the shape. The price of the equipment varies greatly according to the model and specifications, so it can be checked directly to the manufacturer.

- Q: I want to make some plastic products. Thank you。 FiveThe four type: first, a one or two meter long, hard, but bent plastic tube. Then there's something like the front end of the syringe. And then a small plastic kettle. Finally, a small thing that can be secured to the mouth of the pipe.

- Second similar things syringe I suggest: as long as you can find a think suitable syringe or other similar things, then take it to the more small machinery plant hopes to solve the problem (fourth questions refer to the answer); two cases of third problems, as long as one or several that simply.

- Q: What kind of equipment do you need and how much will it cost to invest?

- Buy a common point in general such injection molding machine is around 1 million, this is the domestic price, if imported, if Taiwan is some 500. Hope to help you.

- Q: I don't know what kind of machine is needed. How can I sell the material after processing? Is there anyone?I want to make a waste plastic (plastic bottle) small processing at home, I don't know what kind of machine is needed. How can I sell the material after processing? How much money does it cost?. Seek expert advice, the more detailed, thank you!

- Friends probably want to make plastic crushing factory! General plastic bottles, such as mineral water bottles, PET, detergent, milk bottles, etc. This is HDPE's.. PET general crushing cleaning, selling chemical fiber plant, HDPE generally sell granulation plant, cleaning, and some injection molding factory is also useful. Just break it and use a crusher.

- Q: Plastics are processed into raw materials. How much raw material and energy do we need to process a kilogram of plastic?

- Is the necessary equipment for extrusion blow molding machine, you must first set up the company, production workshop, production equipment, testing equipment, inspection personnel and production licenses for the government, as the raw material is plastic particles, costs and profits can not be known, see you how to operate.

- Q: When the engineering plastics in the processing, because it is not often around breaking chip, tool and workpiece, not only affects the working efficiency, but also the workpiece surface galling, do not know can not think of a way from the cutting tool and cutting amount? Who can give me some good advice? Please.

- Angle of feed, generally use 60 degrees bevel angle, the amount of cutting does not exceed 1MM. Also, adjust the cutting speed.

Send your message to us

FRP Filament Winding Machine for Large Scale in High Quality of New Design

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 22 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords