Forming Machine for Prestressed Hollow Core Panels

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 5 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Forming Machine for Prestressed Hollow Core Panels

1. Structure of Forming Machine for Prestressed Hollow Core Panels:

Forming Machine for Prestressed Hollow Core Panel works on the long-line table, using the high-strength low-relaxation steel strand as the guide, using the pushing work method to forming the concrete hollow-core slab. The slab have the advantages of smooth surface, high-density structure, capable of making construction slabs of 4.2m to 18m. The GLY series concrete hollow-core slab mainly used on the larger bay workshop, school, hospital, shopping mall, office building, bulk storage plant etc.

2. Main Features of Forming Machine for Prestressed Hollow Core Panels:

• One machine can make one slab lower cost, high Wear-resistant, long service life.

• In case of quality problem the company provide free replacement.

• Provide technical support for free.

• Provide consumers with regular visits

• Simple structure, easy operate, less wear parts

3. Forming Machine for Prestressed Hollow Core Panels Images:

4. Forming Machine for Prestressed Hollow Core Panels Specification:

Type | Aperture & diameter | Number and diameter of wires | Max span | Total power | Productivity (m/min) | Max. Load (KN/m2) | Overall dimension (mm) | Weight (kg) |

GLY180-1200 | 11/ peach | 12/9.5or12.7 | 9 | 18.5 | 1.1-1.3 | 16.16 | 2900X1500x1200 | 3300 |

GLY200-1200 | 8 /peach | 10/9.5or12.7 | 10 | 22 | 1.1-1.3 | 13.22 | 3700X1550X1550 | 5300 |

GLY250-1200 | 8/ peach | 10/12.7 | 12.6 | 33 | 1.1-1.3 | 11.1 | 3700X1550X1500 | 6200 |

GLY300-1200 | 6 /peach | 8/12.7 | 15 | 40 | 1.1-1.3 | 10.83 | 3700X1550X1500 | 6900 |

GLY380-1200 | 8 /rhomb | 8/12.7 | 18 | 39.2 | 0.8-1.0 | 12.27 | 4600X1850X1600 | 7500 |

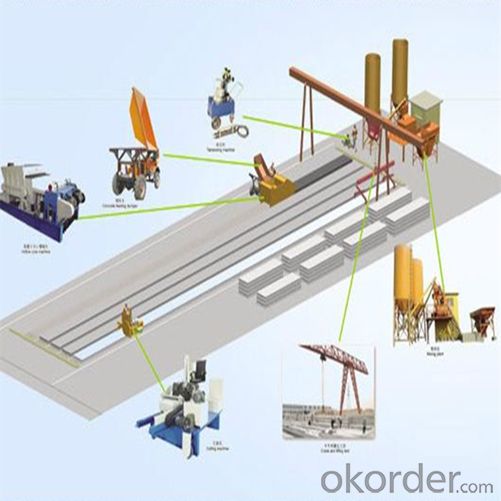

Production Layout

5. Packing & Delivery

• Wire cables are used for fastening the machine on the trailer or inside the container.

• Machine covered with plastic film.

• Machines can be packed in tarpaulin or wooden case according to customer’s needs.

6. FAQ:

We have organized several common questions for our clients, may help you sincerely:

• What information we need to confirm with you before send a formal offer?

What kind of slab you want to make, wall panel, roof panel, lintel or something else?

Do you have exact slab size (slab thickness and width)? If not, please tell us the slab span, we will give you suggestion.

• Have you use this kind of machine before?

Our machine is totally different from European machine. Please don’t follow their instructions.

• How long can we receive the product after purchase?

In the purchase of product, within 20 working days we will arrange the factory delivery as soon as possible. The specific time of receiving is related to the state and position of customers. Commonly 35 working days can be served.

7. Why choose us:

• 30 years manufacturing experience.

• Constitutor of the

• More than 10 patents.

• Passed ISO9001:2000 quality system certificate.

• More than 10 types of machine and over 100 models for choose.

• Supply complete set of technology and equipment solution.

• We can design and manufacture all kinds of concrete forming equipment according to customers' demands. Meanwhile we can even more provide our customers a complete set of technology and solution for all producing flow.

- Q: Construction Engineering, moving equipment and stationary equipment, respectively

- Such as separator, filter, oil filter, buffer, scrubber, absorption tower, drying tower, tower, gas cylinder, deaerator etc.. Storage equipment (code T). Such as various types of tanks, tanks and so on.

- Q: What are the details of construction machinery parts in sand casting?

- (3) equipped with fittings, installation type air switch and air shower room installed in the furnace. (2) all kinds of vehicle tracks, transmitters, differential pressure and buttons are all materials other than the equipment body. (3) rotating filter network circulating water system for equipment, induction phase shifter, manhole and other various products embedded parts, clean bench, meter, scientific research and other functions of the machine, and pipeline safety device, railing, peep hole, ventilation air heater (1):

- Q: What are the sectors of machine building and parts processing?

- 3., machinery manufacturing is also a kind of industry, many industries have parts manufacturing, processing links. Therefore, the processing of parts does not belong to a particular industry.

- Q: What are the main functions of construction equipment monitoring system?

- The total of the console cameras and auxiliary equipment (such as camera, PTZ, shield) control generally adopts the bus mode, a control signal to the camera near the terminal in the terminal box decoding, decoding box will total console from the control signal encoding solution, a control action command signal, a variety of actions to go camera control and auxiliary equipment (such as lens zoom, pan rotation etc.). In the case of some cameras that are close to the control center, in order to save money, the command signal, which is the "on or off" signal, can also be sent directly by the console. In short, according to the composition of the system and requirements, can be considered in order to complete the overall console design requirements or order requirements.

- Q: How are the machine parts stacked?

- Classification ah! Put small pieces of different sizes and functions into boxes and attach labels; larger items can be placed outside in a certain order (for example, function, length, value, etc.)

- Q: What are the safety protection equipment, machinery and equipment, construction machinery and accessories for construction enterprises?

- Different types of work, security appliances are not the same. For buildings, the main safety helmets, safety nets, safety belts (San Bao), etc., for electrical operators, mainly insulated shoes, insulating gloves, insulation rod, insulation table, etc.

- Q: What are the world famous mechanical equipment exhibition?

- 1, the German BMW Exhibition (BAUMA) sponsored by: Messe M nchen GmbH, held every three years, has held 30 sessions, the thirty-first will be in April 2016 11-17 in the German city of Munich exhibition centre. The German international engineering machinery, building materials machinery, mining machinery, construction vehicles and Equipment Expo is the world's largest and most influential international engineering machinery, building materials machinery, mining machinery industry exhibition, every three years regularly held in Munich in germany. The fair combines science and technology, trade, information and technical cooperation

- Q: Construction machinery production need to deal with what documents?

- Two, enterprise legal person business license (copy), with enterprise legal person business license duplicate copy, search three, all levels of safety production responsibility system and safety production rules and regulations directory and documents, operation procedures directory

- Q: What are the construction materials, components, fittings and equipment in construction?

- Board: cast-in-place slab, prefabricated slab, prefabricated hollow slab, reinforced concrete slab, wood board. The wall, brick wall, concrete wall, roof parapet, wall light. Door: solid wood door, plywood door, steel door. Window: window, wooden window, Aluminum Alloy window, plastic steel window. The building is in addition to other parts of the building and construction of houses built some auxiliary components, such as scaffolding, construction with pipe thread adjuster, building rod, triangle construction support, reinforced joints etc..

- Q: What is the difference and connection between equipment manufacturing and machine building?

- In accordance with the standards of classification, including metal products, general machinery manufacturing, machinery manufacturing, transportation equipment manufacturing, electronic and communication equipment manufacturing industry, electrical machinery and equipment manufacturing, instrumentation and office machinery manufacturing seven deducted 186 small consumer related manufacturing industry after class. Equivalent to the European countries referred to as "capital goods manufacturing", that is, we often say "the production of means of production industry."".

Send your message to us

Forming Machine for Prestressed Hollow Core Panels

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 5 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords