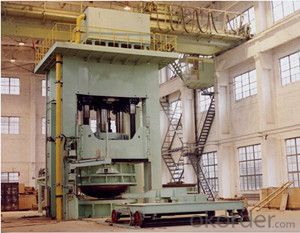

Forging Hydraulic Press Train Wheel Press

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 2 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

TYHI’s train wheel presses are used mainly for forging solid wheels for passenger and freight trains. Our presses can produce locomotive wheels, freight train wheels, common passenger train wheels, bullet train wheels (250km/h) and high-speed passenger train wheels (350km/h). Our presses also can produce rail-bound transportation wheels for underground and light rail, and industrial wheels such as crane wheels, port machinery wheels and metallurgical mining wheels.

Our train wheel presses mainly include 50MN, 60MN, 80MN, 90MN and 100MN models.

Our main products include lifting equipment, forging equipment, rolling equipment, excavation equipment, coke oven equipment, coal chemical equipment, wind power generating equipment, oil film bearings for rolling mills, gear drive equipment, train wheels and axles, forgings and castings and project contracting.

Our key products include our 1200t EOT crane, our 500t ladle crane, our 75m³ shovel for mining, our Φ180mm continuous rolling production line, our 110 MN aluminum alloy extrusion press and our 7m top charging coke oven equipment.

TYHI’s products are widely used in the metallurgical, mining, energy, transportation, aerospace, chemical, rail, ship building, environmental protection and various other industries. Many products designed and manufactured by TYHI have filled gaps in the domestic market. Furthermore, we have created 360 nationally and internationally recognized products which have been exported to approximately forty countries and regions.

TYHI is now delving further into the development of the rail, engineering machinery, new energy, and maritime equipment fields. We have established a new production base in the Binhai New Area of Tianjin to facilitate the transportation and export of large-sized equipment. Our second wheel production line is currently under construction. We have also established production lines for wheels, axles and wheel sets for use at speeds above 200 km/h.

We are now turning our focus to international markets which we are certain can benefit from our high quality products and service. As we are constantly innovating and improving, we have no doubt that we will meet and even exceed our customers’ expectations.

- Q: How is this pneumatic binder? What's wrong with it? Stamping machine above.

- Yes, but i will not use it as if it were a manual switch?

- Q: The word punch how to make sentences

- Punching machine noun engin

- Q: How does punch press? To the detailed classification, the best sort by tonnage

- JB21-160T open fixed punch, JB21-200T open fixed punch, JB21-250T open fixed punch, J21S5T open fixed punch, JB21-160T open fixed punch, JB21-200T open fixed punch, JB21-250T open fixed punch, J21S-

- Q: Pneumatic punch a work, the inverter shows how the matter

- Punch has its own characteristics, it is in the vicinity of the dead center to achieve the stamping process, in contact with the material, the torque required suddenly increased,

- Q: How to improve the capacity of a single punching machine

- The effective production capacity of the press is only in its actual actual stamping process, so all non-stamping work is wasted, if you want to enhance the stand-alone production capacity, it is necessary to start from the shortened downtime, because the machine itself to improve the run (run

- Q: Punching machine punching force is generally how much

- The calculation formula of thrust and bending is not very consistent, it is recommended to check the manual.

- Q: What is the purpose of the punch

- Such as our use of the switch socket, cups, cupboards, plates, computer chassis, and even missile aircraft ... ... there are many accessories can be used to produce through the punch out of the mold.

- Q: What is the servo punch?

- Servo punch to servo motor as a direct source of power, through the screw, crank connecting rod and elbow bar, etc., the motor drive generated by the drive into the linear motion of the slider, the use of servo motor programmable control characteristics, perfect control

- Q: How does this door's profile come out? The

- First of all, according to the user given the drawings or the proposed style (with the style of the production);

- Q: Manual punching machine operation method?

- Before use the lubrication points need to refuel.

Send your message to us

Forging Hydraulic Press Train Wheel Press

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 2 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords