Flow Type Pallet Racking Systems for Warehou

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 100 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description:

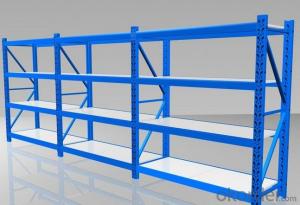

Flow Type pallet racking system is commonly used in manufacturing industry and logistics inductry, like logistic centre, also production line and plant, for many goods will be move in flow for purpose.

it's in large quantity and save a lot of laboe working. It is used in high warehouse and production plant. Automatic production use this kind of racking system.

Feature:

· Customized design

· Big loading weight

· Professional usage

Images:

Specifications:

Loading weight | 500KG |

Height | 3-5M customized |

FAQ:

What is for purchase?

Pallet size,good weight, warehouse sapce and height, etc.

How is quality?

The production use professional roll forming technology and material of steel for production have strict test.

How project installation?

We also could send engineers to users's spot to carry out installation.

- Q: What are the logistics and warehousing equipment? The more, the better

- Plastic tray tray, wooden pallets, steel pallets, storage cage, tchouk frame, logistics trolley, forklift cage, shelves of light, medium, heavy.

- Q: What are the types of logistics equipment?

- According to the special functions of the equipment, it can be divided into transportation equipment, storage and storage equipment, loading and unloading equipment, circulation processing equipment, packaging equipment, information processing equipment, etc..

- Q: What are the key functions of warehouse management logistics informatization construction?

- In the warehouse management system, customer first is the initial inventory management (initial information collection), when the inventory is automatically increased after receipt when purchasing, sales, inventory system automatically reduced, and parity did not affect changes in the allocation of inventory, so inventory only through the inbound or outbound change or not change and, the administrator can query specific types of inventory. --- warehouse management, EBIG logistics, warehousing management system (WMS)

- Q: How to carry out logistics warehousing operations?

- Whether we can allocate human resources and operate effectively is one of the most important criteria for efficient warehouse management.Artificial management technology can help those who are troubled employees warehousing enterprises, auxiliary management decision-making staff number storage required, and can adopt the labor standards and engineering support system to evaluate the performance of warehouse workers. In addition, companies should provide incentives for teams of employees, not individuals, to maximize the team's potential. There are many warehouse management systems lack of artificial management and performance evaluation considerations, or the lack of manual management of this function of convergence.

- Q: How to do the warehouse logistics supervisor?

- Understand existing problems of similar warehouse. Any problem has its causes, and any problem has its solution.

- Q: What are the main differences between the electricity supplier warehouse and the traditional warehouse?

- Average order lines are few. Traditional retail logistics has dozens, even more, hundreds of orders line, these goods may be distributed in all corners of the warehouse, according to order picking, warehouse go round to complete order picking. But only a few of the electricity supplier logistics orders, in most cases such as Jingdong, such as dangdang is no more than 10, a few such as shop No. 1 will be between 10 to 20, if still use the traditional retail logistics commonly used to order not picking, picking up for each trip only a few parts need to go a large number of road in the warehouse. A large number of actual combat statistics show that as much as 70% of the time spent in the picking process is on walking. Therefore, it is necessary to design a picking order, and can complete multiple orders at the same time, to improve the efficiency of picking, such as first picking, picking, planting, or picking the same model.

- Q: What's the sea cucumber logistics equipment?

- Sea cucumber is a kind of spiny animal that grows on the bottom rock of the sea or between seaweeds. It is named after its "warm, warm and sufficient ginseng". Sea cucumber as a rarity, its nutritional value is high, the treatment effect of magic, has long been recognized and praised.

- Q: What are the commonly used facilities in the logistics industry?

- Unloading machinery and equipment (loading and unloading machines are common: bridge cranes, Longmen cranes, gantry cranes, and some mobile cranes. Transportation: belt conveyor, bucket elevator, screw conveyor, rod conveyor, pneumatic conveyor and so on

- Q: What role does warehousing play in logistics?

- The purpose of warehousing is to meet the needs of the upstream and downstream supply chain. This differs greatly from the past in meeting the needs of the customer in depth and breadth. Who commissioned, who demand, who is the customer; customer may be the upstream producers, may be a downstream retailer, may also be the enterprise, but can not only meet the warehouse direct "customers" demand, should also meet the "indirect" customer is customer demand; storage should be integrated into the supply chain. Downstream, according to the overall demand of supply chain to establish the role of service and storage.

- Q: Common equipment for warehouse logistics equipment

- Warehouse logistics: solid shelves, stacking machines, sorting lines, conveyor equipmentVertical conveying type: Reciprocating lift, continuous elevator, intermittent elevator and hydraulic lifting platformFlat conveyor: belt conveyor, chain machine, roller and other non-standard conveying equipmentNon-standard equipment: climbing belt conveyor (chain machine), turning belt conveyor (chain machine), screw conveyor, etc.

Send your message to us

Flow Type Pallet Racking Systems for Warehou

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 100 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords