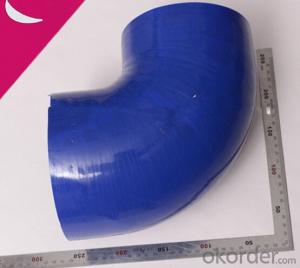

Flexible Water Discharge Hose Good Quality

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10 m

- Supply Capability:

- 10000 m/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

Rubber Hose Without Flange normally made by rubber material according to customer’s requests, and also package in bundles or nude packing directly put into container.

Black EPDM/SBR blended compound

Tube: Flexible Water Discharge Hose

Material:Black EPDM/SBR blended compound

Cover:SBR,EPDM

Reinforcement: by Nylon cord with helix steel wire embedded

Temperature:-40°F to +194°F (-40°C to + 90°C)

Standard Hose Length: 135ft (40m), 35ft (10m)

Scope of Application of the pipes

Rubber Hose is a concrete delivery for combined use with other concrete pipelines in concrete placement operations. It can be widely used in the construction of various types of concrete structures like industrial and civil buildings, bridges, roads, and other types of infrastructure.

It is used for the suction of normal temperature water & neutual liquid in the project of industrial mining, civil engineering and hydro project the hose is also not allowed to be used in any location where any combustible or explosive material exists or a cave-in may occur.

Product Advantages:

OKorder's Hose Without Flange Channels are durable, strong, and safety.

Main Product Features:

· Premium quality

· Prompt delivery & seaworthy packing (5-10 days)

Reliable performance

Easy to weld

High safety.

· Professional Service

Technology parameters:

Size | Layers | O.D. | W.P. | Weight | Length | ||

I.D.(mm) | inch | Layers | O.D.(mm) | Mpa | kg/m | lb/ft | m |

25 | 1 | 2 | 49 | 1.5 | 1.25 | 0.84 | 40 |

32 | 1-1/4" | 2 | 57 | 1 | 1.47 | 0.99 | 40 |

38 | 1-1/2" | 3 | 60 | 0.8 | 1.7 | 1.14 | 40 |

45 | 1-3/4" | 4 | 69 | 0.8 | 2.1 | 1.41 | 40 |

51 | 2" | 3 | 72 | 0.7 | 2.2 | 1.48 | 40 |

51 | 2" | 4 | 74 | 0.8 | 2.4 | 1.61 | 40 |

64 | 2-1/2" | 3 | 86 | 0.7 | 2.8 | 1.88 | 40 |

64 | 2-1/2" | 4 | 87 | 0.8 | 3 | 2.01 | 40 |

76 | 3 | 4 | 100 | 0.6 | 3.6 | 2.42 | 40 |

76 | 3 | 5 | 102 | 0.7 | 3.8 | 2.55 | 40 |

102 | 4 | 4 | 125 | 0.5 | 5.3 | 3.56 | 10 |

102 | 4 | 5 | 127 | 0.6 | 5.6 | 3.76 | 10 |

127 | 5 | 4 | 152 | 0.5 | 7.9 | 5.30 | 10 |

152 | 6 | 5 | 178 | 0.6 | 8.5 | 5.70 | 10 |

152 | 6 | 6 | 181 | 0.5 | 9 | 6.04 | 10 |

203 | 8 | 8 | 230 | 0.5 | 14.61 | 9.80 | 10 |

254 | 10 | 8 | 296 | 0.5 | 20.75 | 14.03 | 10 |

Packing:Plastic inner side and woven outer side,Color packing or customized

- Q: Can black soft rubber pipes be used as water pipes? Why is there a pungent odor?

- Black rubber hose is not suitable for water pipes, black rubber tube, or all the use of recycled rubber is very high; and black rubber tube is generally industrial use.

- Q: How do you get the joint of the plastic pipe?

- Special fittings for plastic pipes and special welding machines for plastic pipes are used. The pipe fittings and pipe heads are heated by melting machine and inserted together.

- Q: What kinds of pipe joints can be divided into? What are the differences between the so-called one - piece pipe joint and other types of pipe joint?

- The pipe joint is divided into a steel pipe joint and a hose joint.The steel pipe joint is provided with a clamp sleeve type, a welding type, a clapboard is connected, a reducing connecting, an oil inlet connection, a combined connection, a pressure gauge connection, a flange connection, etc..A seizure type hose connector, removable, plug-in, you said one pipe joint is extruded hose connector, connector and sleeve is one, there is a separate.My side is to do this piece, the United States PARKER Parker hydraulic hose, joints, assembly, quick change connector.

- Q: What kind of material is medical rubber tube?

- General medical grade silicone tube, environmental protection, no odor, in line with food grade certification FDA/SGS/ROHS/LFGB, widely used in the medical industry. Friends do not understand, you can contact me. New silicon rubber pipe

- Q: The main features of Linatex rubber tube or what are the characteristics?

- The types and characteristics of Linatex rubber tube:Linatex:95% pure natural rubber is made of fresh latex and processed by liquid phase process. Excellent resistance to wet grinding, super elongation, high strength, resilience and tensile strength.Linard 60: silicon reinforced natural rubber, with high wear resistance, high resilience, cutting resistance, tear resistance and so on.Linatrile: silicone reinforced rubber. It has the properties of wear resistance, oil resistance, aging resistance, fatigue resistance and good air tightness.

- Q: Toilet hose and water tank joints leaking, how to repair?

- There is a rib joint. It may be that the rubber sealing ring in the joint is not installed or damaged. Turn off the water source, disassemble, check and replace;

- Q: How often do the oil - resistant rubber pipes undergo atmospheric pressure testing?

- Bending test: after bending the hose to a certain extent, measure the minimum outside diameter of the bending part and the ratio of the outside diameter before bending, the passing capacity of the steel ball and the bending force when the tube is pressurized.

- Q: The pipe of the gas water heater is buried in the wall. It is made of nylon tube and rubber tube. Is it possible to use rubber tube?

- With respect to the through wall gas safety management regulations, it is clear that hoses can not be used through walls.

- Q: Do you need a hose connection to connect the ventilation pipe to the exhaust fan? Under what circumstances? Under what circumstances?

- The exhaust fan running noise and vibration is relatively large, the wind pipe made of sheet iron, the thin wall affected by the fan vibration will produce two times the noise, so the general air pipe to both sides of fan and soft joints, if no one in the floor or the condition of small diameter pipeline can not be added.

- Q: What are the types of metal hose couplings?

- DPJ external threaded end metal hose joint is an extension of JB/GQ 0552, /83, D95-5 metal joint;The metal joint is made of zinc alloy. The surface is zinc plated, frosted or chrome plated. The structure is close, without porosity and high strength. The metal hose is connected reliably and has beautiful appearance;The metal joint is an end connection and a linear connection for connecting the metal hose to the case;Suitable metal hose: JS, JSH, JSB, JSHG;It is recommended to use an inch metal hose joint or a metric thread metal joint;Can be customized a variety of non-standard metal hose joints, special metal joints.

Send your message to us

Flexible Water Discharge Hose Good Quality

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10 m

- Supply Capability:

- 10000 m/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords