Roberts Plywood Film Faced Marine Plywood for Building

- Loading Port:

- Lianyungang

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m³

- Supply Capability:

- 100000 m³/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Specifications

SIZE:1220X2440;1250X2500 , ETC.

2.BLACK/BROWN/RED FILM

3.CORE:POPLAR/COMBI/HARDWOOD

4.GLUE:MR/MELAMINE/WBP/REAL PHENOLIC

Description

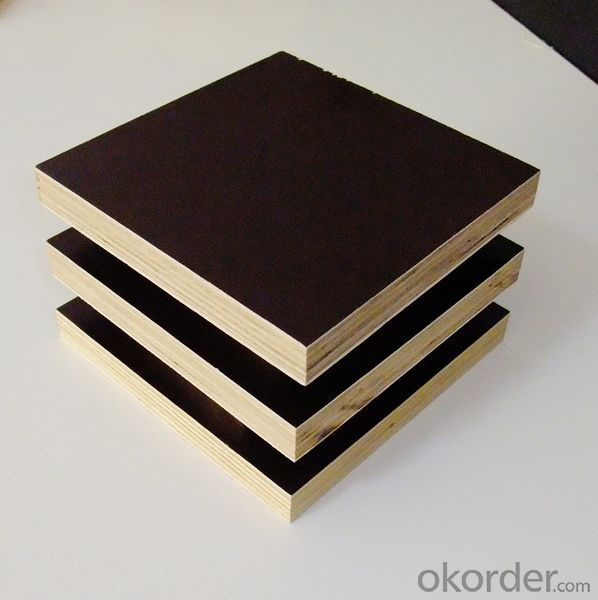

Product Name | WBP/ melamine glue 18mm brown/black film faced plywood |

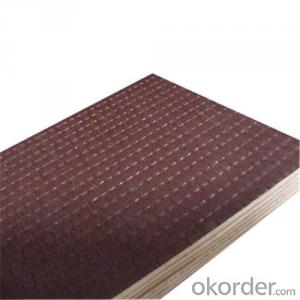

F/B | Black film, brown film, red film, anti-slip film |

Grade | first grade AAA |

Core | Poplar, hardwood,combi, Eucalyptus, birch,Pine |

Glue | Melamine/WBP/MR |

Thickness | 12mm,13mm,14mm,15mm,16mm,17mm,18mm |

Specification | 915MMX1830MM,1220X2440mm |

Moisture Content | 14%-18% |

Package | Seaworthy packing |

MQQ | 1X20’GP,22CBM |

Price terms | EXW, FOB, CNF, CIF |

Payment | T/T, L/C at sight |

Delivery time | Usually 15 days after receipt of the original L/C or the 30% advanced payment |

Supply Capacity | 3000 CBM/Month |

Usages: | Can be widely used for building concrete, etc |

Remarks: | Top class equipment with top class produce technique; Credit first, Fair trading |

Features

1. Transference to concrete is set up very easily, so good for construction work. (There is no need for any transference preparation.)

2. After installation of concrete, the surface looks like a mirror. (the cement does not stick.)

3. You are able to use film faced plywood until the plywood itself is damaged. (Strong with nailing and knifing)

4. Environmentally friendly. (Even after incineration, there is no hazardous substance.)

5. It can be used for a long time, and for the initial price paid for the material, you will feel its worth over time

FAQ

1.free samples are available

2.MOQ is one 40HQ container

3.delivery time 30 days after getting deposit

4.payment term T/T or L/C at sight

- Q: What does plywood mean and its synthesis?

- Plywood is cut from the wood section into a veneer or cut from the wooden square cut into thin wood, and then made of adhesive glue from the three or more layers of plate-like material

- Q: How do you choose plywood in plywood production?

- Another problem is the growing number of furniture produced by the panel, although these furniture, "cypress" and other grain appearance,

- Q: What is the best way to fix multi-layer plywood?

- The main tree species are: camphor, willow, poplar, eucalyptus and so on.

- Q: Furniture solid wood and plywood which is better? Such as bed `wardrobe` TV cabinet `table

- Plywood also has solid wood plywood, in general, solid wood panels will be more expensive than plywood

- Q: What is the use of plywood for construction?

- The outermost front panel is called a panel, the back is called a backplane, and the inner board is called a core plate

- Q: What are the defects in plywood material?

- Fissure check The short separation of the panel fiber usually does not start from the side of the board, not all extending through the thickness of the veneer.

- Q: What is the difference between plywood glue E0E1?

- Urea-formaldehyde glue: moisture-proof glue / for interior decoration, furniture, can not be used for outdoor.

- Q: What is a joinery board?

- Blockboard core board should be the same species or similar properties of the tree species, water content of 6 to 12%. Core width is not greater than three times the thickness, do not allow a larger crack, holes and so on

- Q: Distinguish between multilayer boards and plywood

- Commonly used plywood type plywood, penta and so on. Plywood can improve timber utilization and is a major way to save wood

- Q: Why is the plywood commonly used in the singular layer

- and take a vertical put a then put the plastic in the horizontal put a then In the vertical put a piece into a plywood

Send your message to us

Roberts Plywood Film Faced Marine Plywood for Building

- Loading Port:

- Lianyungang

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m³

- Supply Capability:

- 100000 m³/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords