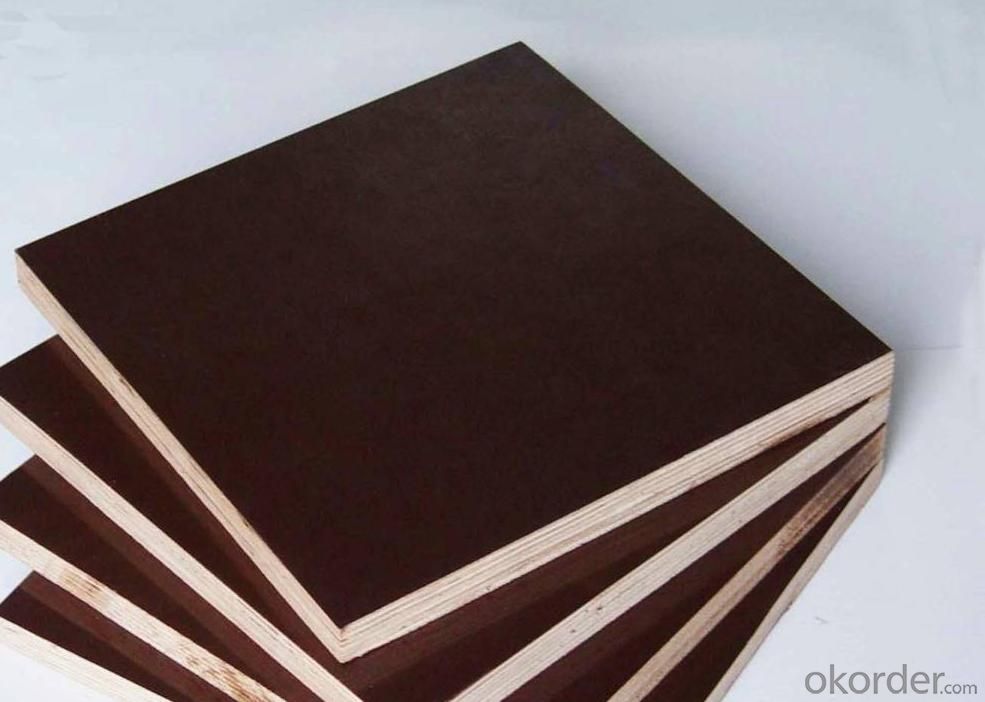

Toledo Plywood - Film Faced Plywood Marine Plywood Construction Plywood

- Loading Port:

- Lianyungang

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m³

- Supply Capability:

- 20000 m³/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Packaging & Delivery

| Packaging Detail: | Pallet/Carton:Water proof plastic paper + plywood pallet + Iron belt: 1*20'GP:18 Cartons:30000m2 1*40'GP:38 Cartons:60000m2 1*40'HQ:44 Cartons:77000m2 |

| Delivery Detail: | 45 Days |

Low Cost High Quality film faced bamboo plywood

The description of film faced bamboo plywood

Bamboo veneer,also know as bamboo panel or bamboo plane,Bamboo veneer is a flake by processing,with planer,bamboo block coning from bamboo pieces bonding,It can serve as face coating material to produce decorative veneer and coating board,Non-woven cloth or special paper is attached to one surface,Which are bonded closely together through cold pressure,then it comes to be decorative veneer and face coating on reinforced floor.

There are four types of bamboo slice presently produced by us,natural color flat press, natural color side press,carbonizedflat press and carbonized side press,Gonerally,the sice is 2500*320/430/640/860*(1-15)mm,(L*W*T),size of breadth and thickness may be changed as necessary.

- Q: according to the use of plywood can be divided into needle plywood and broadleaf plywood.

- moisture content. Between 12 and 14% (according to Chinese national standards, Ⅰ, Ⅱ plywood absolute moisture content of not more than 13%;

- Q: The structure of the plywood at the same time meet two basic principles

- the front panel is called the panel, the back of the table is called the back plate; the core

- Q: How do you choose plywood in plywood production?

- But should be described in the name of the product, such as "cedar veneer plywood", or "fir slices plywood", or "cherry wood trim".

- Q: How do I determine if plywood contains formaldehyde?

- At the same time, in the purchase of furniture, try to choose the wooden rather than plywood production

- Q: What is the type of plywood editing?

- decorative plywood (for construction, furniture, vehicles and ship decoration materials), the general use of plywood (for packaging, bedding and other uses)

- Q: Multilayer plywood with what method is fixed

- Plywood is cut from the wood section into a veneer or cut from the wooden square cut into thin wood, and then made of adhesive glue from the three or more layers of plate-like materia

- Q: Ordinary plywood is divided into four categories

- According to different density, divided into 80, 70, 60 three categories. Quality level for the premium, one, two three

- Q: Multilayer board, also known as three plywood and plywood

- . Its main advantages and disadvantages of raw materials, Liu An core 1.2m.4m each board price of 10-20 yuan. And the peach core and poplar will be cheaper.

- Q: Material for the plywood defects which

- Decay rot due to the invasion of wood rot fungi, the cell wall material decomposition, resulting in loose wood, strength and density decreased, wood tissue and color are often changing.

- Q: The usual length and width specifications are:

- Solid wood refers to pure solid wood, that is, all materials are not re-processed natural materials, do not use any furniture made of wood furniture.

Send your message to us

Toledo Plywood - Film Faced Plywood Marine Plywood Construction Plywood

- Loading Port:

- Lianyungang

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m³

- Supply Capability:

- 20000 m³/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords