Fiberglass Mat Tissue Chopped Strand Mat for FRP Usage

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10000 kg

- Supply Capability:

- 200000Kg Per Month kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Brief Introductions

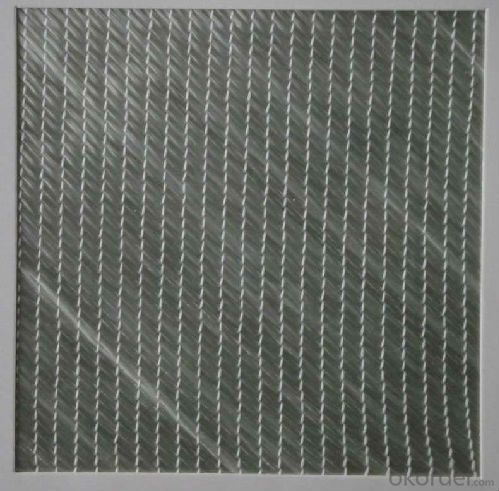

E-Glass Stitched Chopped Mat (450g/m2~900g/m2) is made by chopping continuous strands into chopped strands and stitching them together. The product has a maximum width of 110 inches. This product can be used in manufacturing boat manufacturing and tubes.

2.Product Features

Fast breakdown in styrene

Good wet-through and fast wet-out in resins, rapid air lease

Superior acid corrosion resistance

3.Product Specifications

Item | Over Density | Moisture Content | Chop Density | Polyester Yarn | Width |

(g/m2) | (%) | (g/m2) | (g/m2) | (mm) | |

EMK300 | 309.5 | ≤0.15 | 300 | 9.5 | 50-3300 |

EMK380 | 399 | 380 | 19 | ||

EMK450 | 459.5 | 450 | 9.5 | ||

EMK450 | 469 | 450 | 19 | ||

EMC0020 | 620.9 | 601.9 | 19 | ||

EMC0030 | 909.5 | 900 | 9.5 |

Special specification can be produce according to customer requirements.

4.Packaging

E-Glass Stitched Chopped Strand Mat is wound onto a paper tube which has an inside diameter of 76mm and the mat roll has a diameter of 275mm. The mat roll is wrapped up with plastic film,and then packed in a cardboard box or wrapped up with kraft paper. The rolls can be horizontally placed. For transportation, the rolls can be loaded into a cantainer directly or on pallets.

Storage:

Unless otherwise specified, E-Glass Stitched Chopped Strand Mat should be stored in a dry, cool and rain-proof area. It is recommended that the room temperature and humidity should be always maintained at 15℃~35℃ and 35%~65% respectively.

- Q: Is fiberglass mat tissue chemically resistant?

- Yes, fiberglass mat tissue is chemically resistant. Fiberglass mat tissue is made from fine glass fibers that are randomly oriented and bound together with a resin binder. This composition allows the material to exhibit excellent resistance to a wide range of chemicals including acids, alkalis, solvents, and oils. It is commonly used in industries such as chemical processing, petrochemicals, and wastewater treatment where exposure to various chemicals is common. The chemical resistance of fiberglass mat tissue makes it a suitable choice for applications requiring corrosion resistance and long-term durability.

- Q: Is fiberglass mat tissue suitable for wind energy applications?

- Yes, fiberglass mat tissue is suitable for wind energy applications. Fiberglass mat tissue is a lightweight and durable material that is commonly used in the construction of wind turbine blades. It provides excellent strength and stiffness, making it ideal for withstanding the high stresses and forces that wind turbines are subjected to. Additionally, fiberglass mat tissue is resistant to corrosion and degradation from UV radiation, ensuring the longevity and performance of wind turbine blades. Overall, the use of fiberglass mat tissue in wind energy applications allows for the production of efficient and reliable wind turbines that can generate clean and sustainable energy.

- Q: How is fiberglass mat tissue used in the production of windshields?

- The unique properties and functions of fiberglass mat tissue make it a crucial component in windshield production. To strengthen and increase the durability of the glass, manufacturers use fiberglass mat tissue as a reinforcement material. In the manufacturing process, a layer of fiberglass mat tissue is inserted between two layers of glass to create a laminated structure. This layer acts as a barrier, preventing the glass from shattering upon impact and holding it together for the safety of the vehicle occupants. By serving as a reinforcing material, fiberglass mat tissue improves the mechanical properties of the windshield. It enhances the impact resistance, reducing the likelihood of cracks or chips caused by stones, debris, or other objects. This reinforcement also provides structural integrity, allowing the windshield to withstand extreme weather conditions and vibrations without affecting its functionality. Moreover, fiberglass mat tissue aids in reducing noise transmission and vibrations. Its sound-damping properties contribute to a quieter and more comfortable driving experience by minimizing external noise from entering the vehicle cabin. Additionally, the use of fiberglass mat tissue enables the production of curved windshields. The material's flexibility allows it to conform to different shapes and contours, enabling manufacturers to create windshields with customized designs and improved aerodynamics. In conclusion, fiberglass mat tissue plays a vital role in windshield production. Its reinforcement properties enhance the strength and impact resistance of the glass, ensuring the safety of vehicle occupants. It also contributes to a quieter driving experience and enables the production of curved windshields with improved aerodynamics.

- Q: Is fiberglass mat tissue safe to handle?

- Fiberglass mat tissue is generally considered safe for handling, but it is crucial to take specific precautions to reduce potential risks. This material consists of delicate glass fibers that, if mishandled, can become airborne and cause skin, eye, and respiratory irritation. To ensure safety, it is recommended to wear personal protective equipment like gloves, safety goggles, and a dust mask while handling fiberglass mat tissue. This will prevent direct contact with the fibers and inhalation of loose particles. Working in a well-ventilated space is also advised to lower the concentration of airborne fibers. Additionally, careful handling is essential to avoid physical injuries. The fibers can be sharp and cause cuts or abrasions if not handled properly. It is advisable to use appropriate tools and techniques when cutting, shaping, or manipulating the material. Proper disposal is equally important when dealing with fiberglass waste. Sweeping or vacuuming the area where fiberglass mat tissue was handled should be avoided, as it can disperse fibers into the air. Instead, opt for damp cleaning methods or specialized vacuum cleaners with HEPA filters to contain the fibers and minimize exposure risks. By adhering to these safety precautions and handling guidelines, the potential dangers associated with fiberglass mat tissue can be effectively minimized, ensuring safe handling and use of the material.

- Q: Is fiberglass mat tissue suitable for insulation in cold storage facilities?

- Cold storage facilities can benefit from the use of fiberglass mat tissue as an insulation material. Fiberglass possesses remarkable thermal insulation properties, effectively blocking heat transfer and maintaining low temperatures in the storage area. Moreover, fiberglass is moisture-resistant and does not absorb water, making it ideal for environments prone to condensation and moisture. The installation of fiberglass mat tissue is simple and offers a cost-effective solution for insulating the walls, ceilings, and floors of cold storage facilities. Ultimately, the use of fiberglass mat tissue plays a vital role in preserving the desired cold temperatures and preventing any thermal leaks in these facilities.

- Q: Is fiberglass mat tissue suitable for aerospace interiors?

- Fiberglass mat tissue is indeed a suitable material for aerospace interiors. This material is both lightweight and extremely versatile, providing exceptional strength and durability. Its widespread use in aerospace applications is due to its ability to meet rigorous fire safety standards, including low smoke and toxicity emissions. Furthermore, fiberglass mat tissue exhibits resistance to moisture, chemicals, and temperature fluctuations, making it an ideal option for the challenging conditions found within an aircraft cabin. Its exceptional sound insulation properties further contribute to its suitability for aerospace interiors, guaranteeing a pleasant and noise-free environment for passengers. All in all, fiberglass mat tissue offers a dependable and effective solution for aerospace interior applications.

- Q: Is fiberglass mat tissue resistant to fading?

- Yes, fiberglass mat tissue is resistant to fading.

- Q: Is fiberglass mat tissue resistant to moisture vapor transmission?

- Indeed, fiberglass mat tissue exhibits resistance to the transmission of moisture vapor. It serves as a remarkably robust and moisture-resistant substance, frequently employed in a multitude of scenarios that prioritize moisture management, including roofing, insulation, and flooring. The design of the fiberglass mat tissue is specifically tailored to impede the passage of moisture vapor, thereby preserving the quality and functionality of the accompanying materials. Given its capacity to resist the transmission of moisture vapor, the fiberglass mat tissue emerges as an optimal selection for environments where moisture control is of utmost importance.

- Q: Can fiberglass mat tissue be used for composite tooling?

- Yes, fiberglass mat tissue can be used for composite tooling. It is commonly used as a reinforcement material in composite tooling due to its high strength, durability, and ease of use. It helps to provide structural support and stability to the tooling, making it suitable for various applications in the composite industry.

- Q: Does fiberglass mat tissue require any surface preparation before application?

- Yes, fiberglass mat tissue typically requires some surface preparation before application. This is to ensure proper adhesion and bonding between the fiberglass mat tissue and the surface it is being applied to. The exact surface preparation required may vary depending on the specific application and the condition of the surface. However, some common steps in surface preparation for fiberglass mat tissue include cleaning the surface to remove any dirt, grease, or other contaminants, sanding or roughening the surface to create a better bonding surface, and applying a primer or other bonding agent if necessary. It is important to carefully follow the manufacturer's instructions and recommendations for surface preparation to ensure the best results and optimal performance of the fiberglass mat tissue.

Send your message to us

Fiberglass Mat Tissue Chopped Strand Mat for FRP Usage

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10000 kg

- Supply Capability:

- 200000Kg Per Month kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords