Top Quality Fiberglass Mesh Cloth Made of Fiberglass Yarn

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Fiberglass Mesh Made of Fiberglass Yarn Top Quality

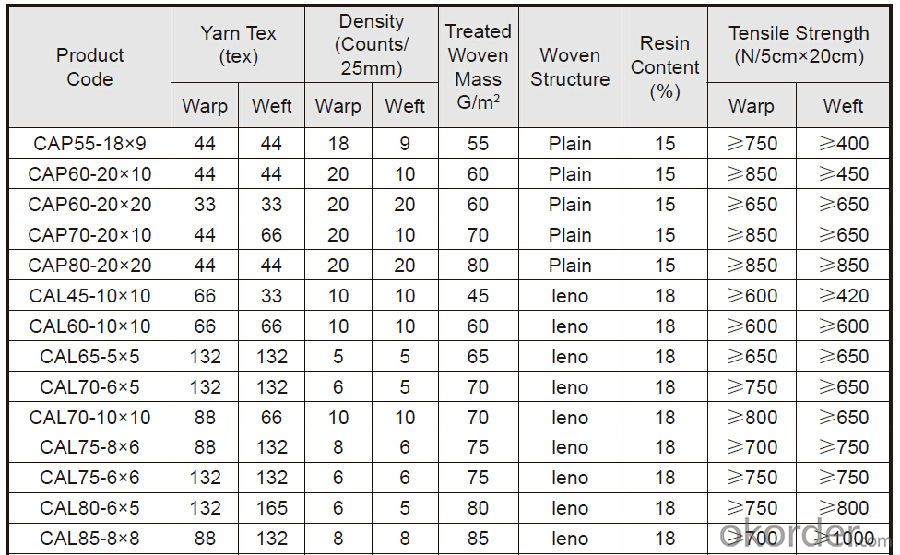

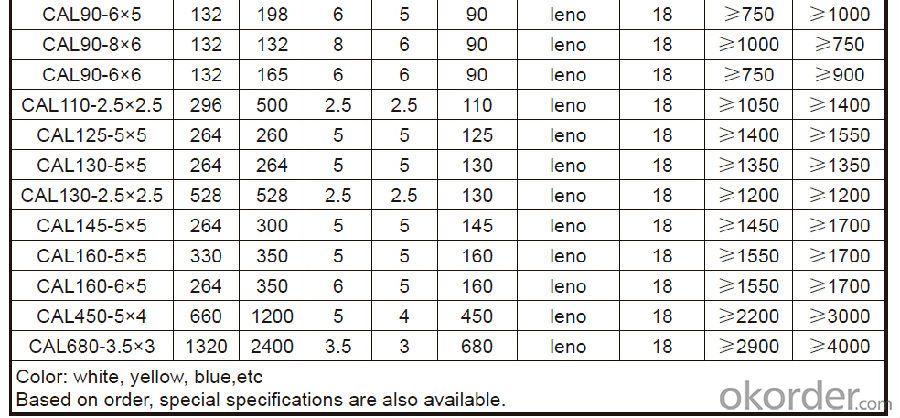

Fiberglass Mesh Specifications

Yarn Type:C-glass/E-glass

Weave Type:Plain/leno

Weight:55-680gsm

Width:100-2200mm

Color:white/yellow/blue,etc

Standing Temperature:500

Resin:15%-18%

Application:Wall Materials

Fiberglass Mesh Features

Fiberglass mesh has tensile strength, small elongation (3%), high elasticity and rigidity, large shock resistance, good chemical resistance, small water absorbent, the scale stability, heat resistance are good, low cost, not easy burn and forming glassy beads at high temperature. Black silicone coated fiber glass mesh fabric is also offered by us.

Alkali-resistant fiberglass mesh has excellent properties including water-resistance, alkali-resistance, flexibility, softness and resistance to aging. It is widely used in reinforcing walls, natural marble, plaster board, artificial stone materials and exterior insulation finishing system.

Fiberglass Mesh Application

1.External thermo insulating composite system(ETICS)&External Insulating Finish System(EIFS)

2.External and internal plaster reinforcement

3.Electrical heating mats

4.Marble slab reinforcement.mosaic carrier

5.Asphalt reiforcement(roof water0proof)

6.Reinforced lightweight construction boards

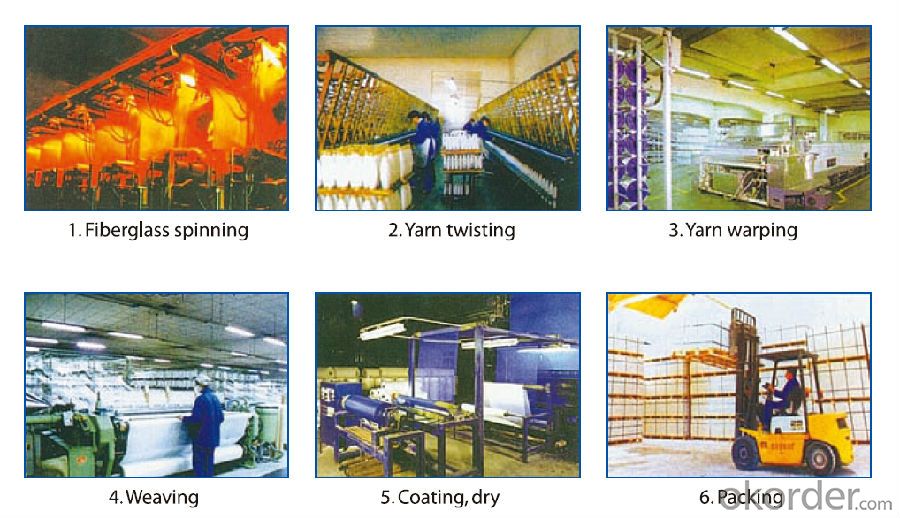

Fiberglass Mesh Progress

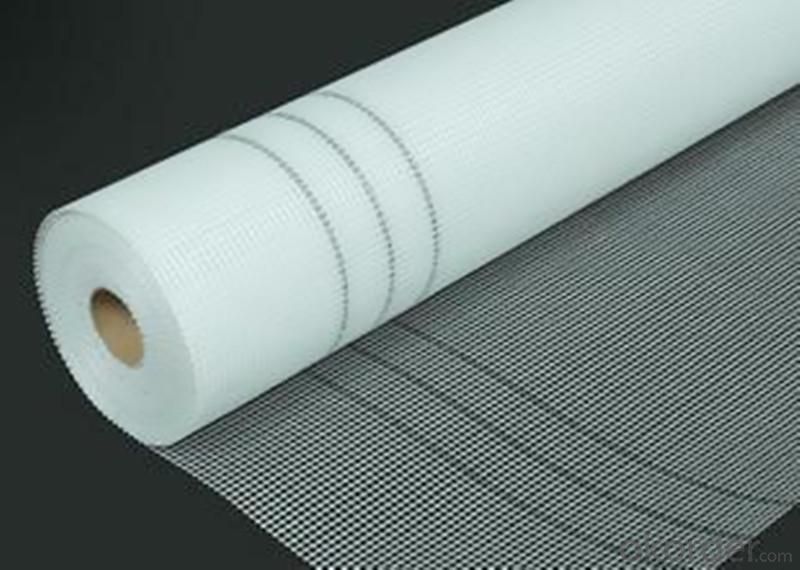

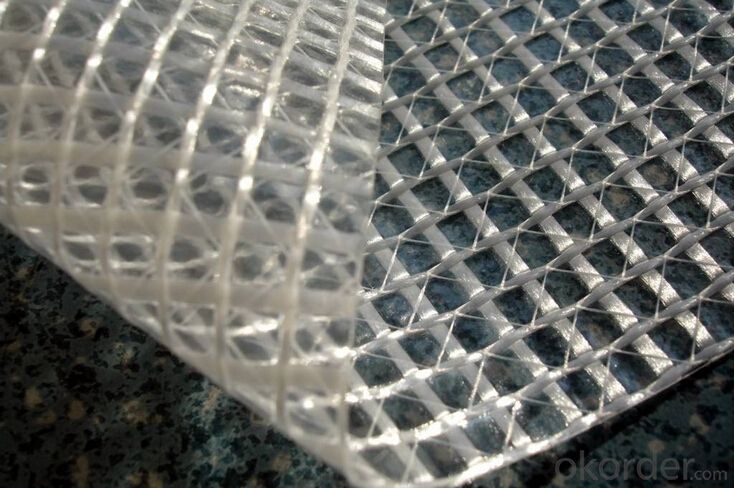

Product Show

FAQ

Q: What is the storage of Fiberglass Mesh?

Store rolls in a cool, dry location

Store away from the direct contact with ground or concrete

Store out of direct sunlight

Protect rolls from weather and other damage

Q: What is the guarantee period of Fiberglass Mesh?

Four years under normal weather conditions and use

Q: What is the Advantage of Fiberglass Mesh?

. Good chemical stability: Alkali-resistant, acid-resistant, waterproof, cement erosion-resistant, and other chemicals' corrosion resistant; and strong resin bonding, soluble in styrene.

. Outstanding craftsmanship include coating enough alkali-resist glue, our coating glue is produced by Germany BASF which can keep 60-80% strength after test in Naoh 28days later, so that guarantee high strength, high tensility, light weight.

. Our fiberglass yarn is supplied by Jushi Group which is the largest producer of fiberglass yarn in the world like Saint Gobain, it's 20% extra strong strength and beauty surface than normal fiberglass yarn.

. Strength retention rate> 90%, elongation<1%, the durability of more than 50 years.

. Good dimensional stability, stiffness, smoothness an difficult to shrink and deformation, good positioning property.

. Good impact resistance and not easy to be teared

- Q: What are the transverse and longitudinal tensile forces of alkali resistant glass fiber mesh cloth?

- No, it should be a large longitudinal tension

- Q: Where is fiberglass mesh better?

- Quality and import gap is not large, but prices are significantly lower. If you do not take the price into consideration, it must be the best of the imports.

- Q: Method for sampling alkali proof glass fiber mesh cloth

- Preparation of polymer mortar must be specially responsible for ensuring the quality of mixing.

- Q: Glass fiber mesh fabric quality, hard and soft for wall, which is better?

- Used on the wall, of course, is more good glue, can increase the degree of alkali resistance. Now there's one kind of urine gum, it's really hard to paint. But there is no alkali resistance.

- Q: Glass fiber mesh cloth bent do to straighten it?

- But the pot of gold coated latex products, the product is soft and hard to control, but also hard to control in a certain range, too soft or strong are not conducive to the construction, to ensure positioning under the condition of hardware and software products in the certain extent is too hard to adjust, very bad hair net, with mortar to live, because the hard product itself has a certain degree of tension, so the network control is not good, not soft products in the construction cannot be caught, so soft and hard to moderate, very convenient construction and good positioning of the product, as long as the use of mortar with trowel with live on the line, if the location is not good, with a trowel wipe when the line will return, affect the insulation effect and effect of the overall construction.

- Q: What is the function of the wall cloth mesh?

- The product has the advantages of stable structure, high strength, good alkali resistance, corrosion resistance, crack resistance, etc., and the enhancement effect is the best, and the construction is simple and easy to do. Mainly used for cement, gypsum, wall, building and other structures to enhance the internal and external surface, crack prevention, is a new type of building materials insulation project.

- Q: Glass fiber mesh cloth, crack mortar, tiling there is no problem?

- It would be to see how the strength of cement foam insulation board, and you paste the process in order to improve the strength, you can use 1 to 1 fiber cement mortar with latex mixing, can increase the thickness and strength, the cost will be reduced, it can in the brick veneer.

- Q: What harm does fiberglass mesh have to people?

- Inhalation of respiratory tract causing lung damage. Three

- Q: Glass fiber mesh fabric stereotypes poor, general use of glue is acrylic emulsion, please add what accessories, you can finalize a better shape

- To increase the penetration of some surface active agent, increase the permeability of the emulsion, adding some phenolic thermosetting resin, melamine formaldehyde and improve sizing effect, to prevent the resurgence of soft, adding cationic film plasticized thermosetting resin while reducing fiber absorption and softening fiber

- Q: Self making method and formula of glass fiber mesh cloth shaping glue

- Glass fiber mesh fabric is based on glass fiber woven fabric as its base material and is coated with high polymer emulsion.Therefore, the utility model has the advantages of good alkali resistance, flexibility, and high tensile resistance at warp and weft direction. The utility model can be widely used for heat preservation, water resistance and crack resistance of walls inside and outside buildings.

Send your message to us

Top Quality Fiberglass Mesh Cloth Made of Fiberglass Yarn

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords