Fiberglass Inner Pipe Wrap Tissue for Pipeline Anti corrosion

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 kg

- Supply Capability:

- 1000000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Brief Introduction: |

Fiber glass pipe wrap tissue is mainly used as anti-corrosion wrapping material for steel pipelines buried underground for oil or gas transportation. It is characterized by high tensile strength, good flexibility, even thickness, solvent & moisture resistance, anti-corrosion and flame retardant.It is well compatible with impregnation bitumen or coal tar enamel the oil of gas pipelines wrapped by Pipe wrapping mat pre-impregnated with bitumen or coal tar enamel acquire capabilities against leakage and aggressivemedia in the environment so that the cost for maintenance and replacement can be reduced significantly and the life time of pile-line may be prolonged up to 50-60 years authoritative tests have proven that the technical target of wrapping mat series can all meet or surpass the technical specification stated in SY/T0079, the oil and gas industry standard of the people's republic of china and meet the requirement in the specification of AWWA C 203 AS WELL this mat is an ideal base material as inner wrap or outer wrap or outer wrap impregnated by bitumen of coal tar enamel. |

Feature: |

Excellent fiber distribution; Excellent tensile strength; Good tear strength; Good flexibility. Application: Fiberglass pipe wrap tissue is mainly used as anti-corrosion wrapping material for steel pipelines buried underground for oil or gas transportation. |

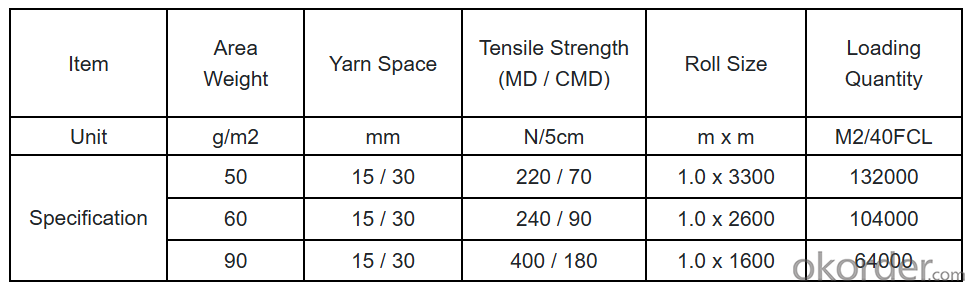

Technical Data Sheet: |

|

Package:

Each roll is wrapped with plastic film, 40 rolls are put into 1x40FCL with wooden pallets. If pallets are not needed, we can load 44 rolls in 1x40HQ. Based on quantity, special package is available.

- Q: Does fiberglass mat tissue provide good acoustical performance?

- Fiberglass mat tissue does provide good acoustical performance. Due to its composition, which includes fine glass fibers, this material is effective in absorbing sound waves and reducing echo and reverberation in a space. Fiberglass mat tissue has excellent sound absorption properties, making it suitable for applications in various industries such as construction, automotive, and aerospace. Its ability to dampen sound and improve acoustics makes it a popular choice for soundproofing walls, ceilings, and floors in buildings. Additionally, fiberglass mat tissue is lightweight and easy to install, further enhancing its appeal for acoustical applications.

- Q: Can fiberglass mat tissue be used for making insulation jackets?

- Yes, fiberglass mat tissue can be used for making insulation jackets. Fiberglass mat tissue is a lightweight material that offers excellent thermal insulation properties. It can effectively trap heat and prevent it from escaping, making it suitable for creating insulation jackets that provide warmth and insulation.

- Q: Is fiberglass mat tissue fire resistant?

- Yes, fiberglass mat tissue is fire resistant. Fiberglass is made from a combination of glass fibers and resin, which gives it excellent fire-resistant properties. It has a high melting point and does not easily ignite or support combustion. Additionally, fiberglass mat tissue is often treated with fire-resistant coatings or additives to further enhance its fire-resistant capabilities. This makes fiberglass mat tissue a popular choice for various applications where fire resistance is required, such as insulation materials, protective clothing, and fireproof barriers.

- Q: Is fiberglass mat tissue resistant to solvents?

- Indeed, solvents are unable to penetrate fiberglass mat tissue due to its inherent resistance. The tissue is crafted from interwoven fiberglass fibers that are subsequently enveloped in a binding agent. This agent serves as a shield, rendering the tissue impervious to solvents. Solvents are commonly employed to dissolve, dilute, or purify substances, but they possess the potential to corrode or harm specific materials. Remarkably, fiberglass mat tissue is meticulously engineered to endure the detrimental impact of solvents, rendering it an exceedingly dependable option for situations that necessitate constant exposure to solvents.

- Q: How does the surface finish of fiberglass mat tissue affect its adhesion to resin?

- The adhesion of resin to fiberglass mat tissue can be significantly influenced by its surface finish. The surface finish pertains to the texture or smoothness of the fiberglass mat tissue. In general, a rough surface finish tends to promote better adhesion to resin. This is because a rough surface provides a larger area for the resin to adhere to, resulting in a stronger bond. Rough surface finishes can be achieved through different manufacturing techniques, such as using coarser fibers or incorporating texturizing agents during production. On the contrary, a smoother surface finish may lead to weaker adhesion. A smooth surface does not offer as much area for the resin to bond with, resulting in a weaker and less durable bond. Smoother surface finishes can be attained by using finer fibers or through additional processing steps to smoothen the surface. When selecting the surface finish of fiberglass mat tissue, it is crucial to consider the specific application and requirements. For applications that necessitate high strength and durability, a rougher surface finish may be preferable to ensure optimal adhesion to the resin. Conversely, for applications where a weaker bond is acceptable or where a smoother surface finish is desired for aesthetic reasons, a smoother surface finish may be chosen. Ultimately, the surface finish of fiberglass mat tissue plays a vital role in determining the adhesion to resin. It is essential to choose the appropriate surface finish to achieve the desired strength, durability, and performance in various applications.

- Q: Can fiberglass mat tissue be used in automotive applications?

- Yes, fiberglass mat tissue can be used in automotive applications. It is commonly used as a reinforcement material in automotive parts such as hoods, fenders, and interior panels.

- Q: Can fiberglass mat tissue be used for making lightweight stairs?

- Making lightweight stairs is possible using fiberglass mat tissue. This material, composed of randomly oriented glass fibers bonded with resin, is widely used in the construction and manufacturing industries because of its strength, durability, and lightweight nature. By layering and molding fiberglass mat tissue, it can create a sturdy yet lightweight structure for stairs. Its impressive tensile strength and dimensional stability make it capable of supporting the weight of individuals using the stairs. Additionally, fiberglass mat tissue is resistant to moisture, chemicals, and UV rays, making it perfect for outdoor or high-moisture environments. Its fire-resistant properties further enhance its suitability for stairs, ensuring safety. In conclusion, fiberglass mat tissue is an excellent option for crafting lightweight stairs due to its combination of strength, durability, and resistance to various environmental factors.

- Q: What is the composition of fiberglass mat tissue?

- Fiberglass mat tissue, also known as fiberglass mat or fiberglass veil, is made up of a combination of fiberglass fibers and a binder material. The fiberglass fibers used in the composition are typically made from silica, a naturally occurring mineral. These fibers are known for their high strength and durability. The binder material used in fiberglass mat tissue can vary, but commonly includes substances like urea-formaldehyde, acrylic, or polyester resins. The role of the binder is to hold the fiberglass fibers together and provide structural integrity to the mat. In addition to the fiberglass fibers and binder, other additives may be included in the composition of fiberglass mat tissue. These additives can include substances such as pigments, fire retardants, or coatings, depending on the specific application and desired properties of the mat. Overall, the composition of fiberglass mat tissue is a combination of fiberglass fibers and a binder material, with additional additives depending on the intended use. This composition allows fiberglass mat tissue to possess excellent strength, flexibility, and resistance to various environmental factors, making it a versatile material used in various industries such as construction, automotive, aerospace, and marine.

- Q: Is fiberglass mat tissue suitable for insulation in industrial applications?

- Yes, fiberglass mat tissue is suitable for insulation in industrial applications. It offers excellent thermal insulation properties, high tensile strength, and is resistant to moisture, chemicals, and fire. Additionally, it is easy to install and provides effective heat retention, making it a reliable choice for insulating various industrial equipment and structures.

- Q: Is fiberglass mat tissue suitable for automotive interiors?

- Automotive interiors can benefit from the use of fiberglass mat tissue. This versatile material is widely utilized in many industries, including automotive manufacturing. It possesses several advantages that make it appropriate for car interiors. To begin with, fiberglass mat tissue offers excellent insulation capabilities. It effectively reduces noise, vibration, and harshness (NVH) levels inside the vehicle cabin. This greatly enhances passenger comfort and the overall driving experience. Moreover, fiberglass mat tissue is lightweight and flexible, making it easy to install in different areas of the car's interior. It can be molded and shaped to fit various components like door panels, headliners, trunk liners, and floor carpets. Its flexibility also allows for seamless integration with other materials, such as sound-deadening substances, to further improve insulation and minimize vibrations. Additionally, fiberglass mat tissue exhibits resistance to heat, moisture, and chemicals commonly found in automotive environments. This renders it a durable and long-lasting material capable of withstanding the unique conditions inside a vehicle. It also resists the growth of mold and mildew, ensuring a clean and hygienic interior. Furthermore, fiberglass mat tissue can be easily coated or laminated with other materials to enhance its aesthetic appeal. It can be finished with various fabrics, vinyl, or leather to match the desired interior design and provide a luxurious feel. In conclusion, fiberglass mat tissue is a suitable material for automotive interiors due to its insulation properties, lightweight and flexible nature, durability, resistance to heat and moisture, and potential for aesthetic enhancements. Its utilization contributes to the creation of a comfortable, quiet, and visually pleasing cabin space for vehicle occupants.

Send your message to us

Fiberglass Inner Pipe Wrap Tissue for Pipeline Anti corrosion

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 kg

- Supply Capability:

- 1000000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords