ETP in MR/ SPCC Steel for General Can Use

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Products: Tinplate

Tinplate and TFS are widely used for making all types of containers such as artistic cans, tea cans, painting cans, chemical package cans and metal printing etc. Its applications are not limited to containers; recently, they have also been used for making electrical machinery parts and many other products.

2. Specification:

Our goods enjoyed high quality both at home and abroad. We can supply tin free steel as follows:

Technical standard | JISG3303 and GB/T 2520-2008 |

Steel Type | MR / SPCC |

Thickness | From 0.15mm to 0.50mm (Tolerance +/- 0.01mm) |

Width | Normally 600-1050mm (Tolerance +3/-0 mm) |

Coating | 2.8/2.8g/m2 , 2.8/5.6g/m2 ,1.1/1.1 g/m2 |

Temper & Annealing | T1-T5, DR7-8, TS230-TH435, T49-T65(+/- 4) |

Surface Treatment | Bright & Fine Stone & Stone & Silver & Matt |

Payment terms | Letter of Credit (L/C), Telegraphic transfer (T/T) |

Price terms | CFR & CIF price term |

Delivery time | Within 60 days after received L/C or T/T down payment |

Packing | High quality shipping packing which contains thin plastic film, rust-proof paper, metal cover, metal angles and strap sand pallet. |

Minimum order Quantity(MOQ) | 25 metric tons (1X 20'' container) |

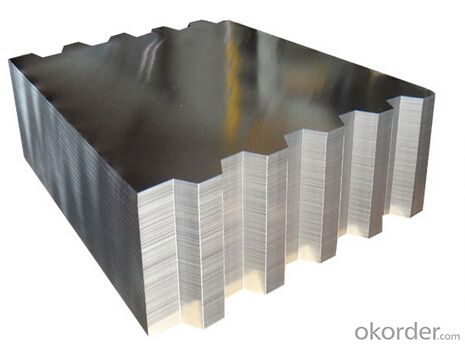

3. Pictures:

4. Features of the factory price/ tin free steel/tinplate/tfs/tmbp/etp/spte:

Beautiful Appearance

Excellent Paintability & Printability

Excellent Formability & Strength

Excellent Corrosion Resistance

Excellent Solderability & Weldability

5. FAQ:

We are one of the main producers in China for tinplate, tin free steel and also TMBP. At present, our productivity is more than 450000 MT/year.

For more information about our products or company, pls contact us freely.

Welcome your enquiries and orders.

- Q: Can tinplate be used for promotional or gift packaging?

- Yes, tinplate can be used for promotional or gift packaging. Tinplate is a versatile material that is durable, visually appealing, and can be easily customized with various designs. It offers a premium look and feel, making it an excellent choice for creating attractive promotional or gift packaging that can leave a lasting impression on recipients.

- Q: How long does tinplate last?

- Tinplate can last for several decades, or even longer, depending on various factors such as the quality of the tin coating, the environment it is exposed to, and the maintenance practices followed.

- Q: How does tinplate contribute to sustainability efforts?

- Tinplate contributes to sustainability efforts in several ways. Firstly, it is a highly recyclable material, which means that it can be reused multiple times without losing its properties. This helps reduce the demand for new raw materials and minimizes waste generation. Additionally, tinplate is often used as packaging material for food and beverages, providing a protective and durable barrier that extends the shelf life of products, reducing food waste. Furthermore, tinplate cans are lightweight, making them more energy-efficient during transportation, thus reducing carbon emissions. Overall, tinplate's recyclability, protective properties, and energy efficiency make it a sustainable choice for various industries.

- Q: What are the common misconceptions about tinplate packaging?

- One common misconception about tinplate packaging is that it is easily dented or damaged. In reality, tinplate is quite durable and can withstand rough handling without losing its structural integrity. Another misconception is that tinplate packaging is not environmentally friendly. However, tinplate is highly recyclable and can be reused multiple times, making it a sustainable packaging option.

- Q: Are there any health concerns associated with tinplate?

- Yes, there are some health concerns associated with tinplate. Tinplate can potentially leach small amounts of tin into the food or beverage stored in it, especially if it comes into contact with acidic or high-salt content products. While tin is considered relatively safe, excessive consumption of tin can lead to gastrointestinal issues and long-term exposure may have adverse effects on health. It is recommended to limit the use of tinplate for storing or consuming highly acidic or salty foods.

- Q: What are the advantages of using tinplate for shipping containers?

- There are several advantages of using tinplate for shipping containers. Firstly, tinplate is highly resistant to corrosion, which ensures the longevity and durability of the containers, even in harsh marine environments. Secondly, tinplate offers excellent strength-to-weight ratio, making it a lightweight yet sturdy option for shipping containers. Additionally, tinplate is easy to form and shape, allowing for efficient manufacturing processes. Lastly, tinplate provides an effective barrier against moisture and oxygen, protecting the goods inside from damage during transportation.

- Q: What are the limitations of printing on tinplate?

- There are several limitations to printing on tinplate. Firstly, tinplate is a relatively rigid material, making it difficult to print on curved surfaces or complex shapes. Additionally, the smoothness of the tinplate surface can pose challenges for adhesion and ink absorption, which may result in poor print quality or color accuracy. Furthermore, the printing process on tinplate is often limited to a single color or a limited color palette, which can restrict the design options and creativity. Lastly, the durability of the printed design on tinplate may be compromised over time due to exposure to external factors such as moisture, heat, or scratching.

- Q: How does tinplate packaging contribute to product protection during shipping?

- Tinplate packaging provides excellent product protection during shipping due to its durability and strength. It acts as a sturdy barrier against external elements such as moisture, light, and air, preventing damage or contamination to the product. Additionally, tinplate packaging's ability to withstand rough handling and stacking ensures that the product remains intact and undamaged throughout the shipping process.

- Q: How is tinplate used in the automotive industry?

- Tinplate is commonly used in the automotive industry for manufacturing various components such as fuel tanks, oil filters, and battery casings due to its excellent corrosion resistance and ability to withstand high temperatures. It ensures durability and helps maintain the integrity of these parts, enhancing the overall performance and safety of vehicles.

- Q: What are the different methods of sealing tinplate containers?

- There are several methods of sealing tinplate containers, including double seaming, soldering, welding, and using adhesive or pressure-sensitive seals. Each method offers its own advantages and is chosen based on factors such as the contents of the container, desired level of seal integrity, and production requirements.

Send your message to us

ETP in MR/ SPCC Steel for General Can Use

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords