Empty Car Care Aerosol Tin Can 52mm, Prime Quality

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50000 PCS

- Supply Capability:

- 300000000 PCS/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Brief description

Content: car care

Size: 52X250mm

Printing: CMYK printing as Per Customer Design

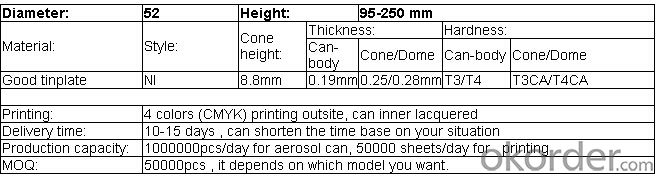

2.Detailed Specification

3. Usage

suitable for insecticide, air freshener, body spray, lighter refill, car care etc

4.Package

5.Appearance Specifications

Diameter(mm) | Type | Straight(mm) |

45mm | Necked-in | 80-220 |

52mm | Necked-in | 80-300 |

52mm | Straight | 76-200 |

57mm | Necked-in | 90-240 |

60mm | Necked-in | 90-240 |

60mm | Straight | 80-300 |

65mm | Necked-in | 80-240 |

65mm | Straight | 80-240 |

6.FAQ

1. Delivery Time:15-25 days, time can be shorten upon customer’s situation

2. Productivity:1,000,000 Cans/Day; 500,000 Printing Sheets/Day

3. MOQ:50,000pcs, but finally upon your size

4. Payment Term: 30% TT in advance, 70% balance against BL copy; 100% by LC at sight

- Q: What is the shelf life of products packaged in tinplate?

- The shelf life of products packaged in tinplate can vary depending on the specific product and storage conditions. However, tinplate is known for its excellent preservation properties, providing a protective barrier against moisture, light, and oxygen. As a result, many products packaged in tinplate can have a relatively long shelf life, often ranging from several months to several years. It is important to note that proper storage and handling practices, including keeping the products in a cool, dry place away from direct sunlight, can further extend their shelf life.

- Q: What are the main innovations in tinplate manufacturing?

- One of the main innovations in tinplate manufacturing is the use of advanced coating technologies, such as electrolytic tin coating, which ensures a uniform and precise layer of tin on the steel substrate. This improves corrosion resistance and enhances the shelf life of the products packaged in tinplate. Additionally, advancements in printing techniques have allowed for high-quality and intricate designs to be directly applied to tinplate, making it more visually appealing and marketable. Furthermore, the development of lightweight tinplate materials has enabled manufacturers to reduce the overall weight of packaging, leading to cost savings and improved sustainability.

- Q: What are the different ways to store tinplate containers?

- There are various ways to store tinplate containers, including stacking them on shelves or in cabinets, using storage bins or containers, hanging them on hooks or pegboards, or placing them in specially designed storage racks or trolleys.

- Q: Can tinplate be used for stationery and office supplies?

- Yes, tinplate can be used for stationery and office supplies. Tinplate is a type of steel coated with a thin layer of tin, making it highly durable and resistant to corrosion. This makes it suitable for applications such as pencil boxes, pen holders, file organizers, and various other stationery items commonly used in offices and schools.

- Q: What are the different tinplate finishes available?

- There are several different tinplate finishes available, including bright, stone, matte, and lacquered. These finishes offer varying levels of shine, texture, and protection to the tinplate surface.

- Q: What are the common closure options for tinplate containers?

- The common closure options for tinplate containers include twist-off caps, screw caps, snap-on lids, and pressure-sealed lids.

- Q: What's the head iron?

- SPTE, which is commonly known as tin, tin plate, thickness of 0.15-0.3mm, width, generally between 300-900mm.

- Q: Can tinplate be used for energy storage applications?

- No, tinplate cannot be used for energy storage applications as it is primarily used in the packaging industry due to its lightweight and protective properties for food and beverage containers. Energy storage requires specialized materials such as lithium-ion batteries or supercapacitors.

- Q: What are the causes of tinplate rusting and how to prevent them?

- The tin surface of the iron sheet is injured and exposed during the machining process to promote corrosion.Prevention: 1, not coated iron sheet, coated with oil after plating thickening. Effectively prevent water invasion and reduce damage to the process.2 can be painted on the iron sheet of appropriate paint, blocking the impact of corrosive substances.

- Q: Tinplate why have white and yellow, tin plating should be white ah, yellow is how to return a responsibility?

- Tinplate itself is no color, it is iron color.

Send your message to us

Empty Car Care Aerosol Tin Can 52mm, Prime Quality

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50000 PCS

- Supply Capability:

- 300000000 PCS/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords