Eleven mm Cold Rolled Steel Rebars with High Quality

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 15000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications of Eleven mm Cold Rolled Steel Rebars with High Quality:

Name | Eleven mm Cold Rolled Steel Rebars with High Quality | |

Diameter | 5mm, 5.5mm, 6mm, 6.5mm, 7mm, 8mm, 9mm, 10mm, 11mm, 12mm, | |

Length | 6M, 9M, 12M or as required | |

Price | Keep lower operating costs so as to offer competitive price for our clients | |

Label | to be specified by customer, generally, each bundle has 1-2 labels | |

Application | Building, construction | |

Invoicing | Actual or Theoretical Weight Basis as buyer’s request. | |

Theoretical weight and section area of each diameter of Eleven mm Cold Rolled Steel Rebars with High Quality as below for your information:

Diameter(mm) | Section area (mm²) | Mass(kg/m) | Weight of 12m (kg) | Pcs/ton |

11 | 95.0 | 0.746 | 8.952 | 111.71 |

Packaging & Delivery of Eleven mm Cold Rolled Steel Rebars with High Quality:

Packaging Detail: products are packed in bundle and then shipped by container or bulk vessel, deformed bar is usually naked strapping delivery, when storing, please pay attention to moisture proof. The performance of rust will produce adverse effect.

Each bundle weight: 2-3MT, or as required

Payment terms: TT payment in advance or Irrevocable LC at sight.

Trade terms :FOB, CFR, CIF

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered byOKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will arrange production. The shipping date is dependent upon the quatity, how many sizes you want and the plan of production, but is typically 1 month to 2 month days from the beginning of production.

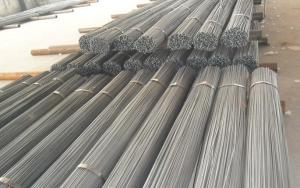

Images of Eleven mm Cold Rolled Steel Rebars with High Quality:

- Q: How are steel rebars stored and handled on construction sites?

- Steel rebars, also known as reinforcing bars, are an essential component in construction projects that require reinforced concrete structures. These rebars are typically stored and handled on construction sites in a systematic and organized manner to ensure their safety and efficient use. To begin with, steel rebars are often delivered to construction sites in bundles or bundles tied using wire or binding materials. Once the rebars are unloaded from the delivery truck, they are usually stored in designated areas known as rebar yards or cages. These areas are specifically designed to accommodate the length, size, and weight of the rebars, ensuring they are kept off the ground and protected from moisture, dirt, and any potential damage. In the rebar yard, rebars are commonly stacked horizontally and grouped according to their size, length, and grade. This arrangement facilitates easy identification and accessibility when needed for construction. Additionally, rebars are often separated by spacers or wooden blocks to prevent direct contact between them, reducing the risk of corrosion or tangling. When it comes to handling steel rebars, construction workers must prioritize safety and follow specific guidelines. Personal protective equipment, such as gloves and safety boots, should be worn to prevent injuries and ensure a secure grip on the rebars. In some cases, workers may use lifting equipment, such as cranes or forklifts, to move and transport rebars to different areas of the construction site. During transportation, rebars should be secured properly to prevent any shifting or falling, which could lead to accidents. Workers should also avoid dragging rebars on the ground, as this can cause damage to the bars or deform their shape, compromising their structural integrity. It is crucial to note that steel rebars should be inspected before use to ensure they meet the required specifications and are free from any defects. Rusty or damaged rebars should be discarded or repaired, depending on the severity of the issue. In summary, steel rebars are stored and handled on construction sites with utmost care and attention. Proper storage in designated rebar yards, correct grouping and separation, and adherence to safety guidelines during handling contribute to the successful and efficient use of steel rebars in construction projects.

- Q: What are the different methods for attaching steel rebars to existing structures?

- There are several methods for attaching steel rebars to existing structures, including drilling and epoxy anchoring, mechanical anchoring using couplers, welding, and using adhesive or resin-based systems. Each method has its own advantages and considerations depending on the specific requirements and conditions of the structure.

- Q: How do steel rebars contribute to the overall sustainability of a construction project?

- Steel rebars contribute to the overall sustainability of a construction project in several ways. Firstly, they enhance the structural integrity and longevity of the building, reducing the need for frequent repairs or replacements. Secondly, steel rebars can be recycled at the end of their lifespan, reducing the demand for new raw materials and minimizing waste. Additionally, the use of steel rebars in construction allows for the efficient use of resources and materials, resulting in a more sustainable and environmentally friendly project.

- Q: Can steel rebars be used in corrosive environments?

- Steel rebars can be used in corrosive environments, but certain precautions need to be taken to ensure their longevity and structural integrity. Corrosive environments, such as those with high levels of moisture, saltwater, or chemical exposure, can accelerate the corrosion process of steel rebars, leading to potential structural damage. To mitigate this risk, various strategies can be employed. One common approach is to use corrosion-resistant reinforcing materials, such as stainless steel rebars or epoxy-coated rebars, which provide an additional layer of protection against corrosion. These materials have proven effective in resisting corrosion even in highly corrosive environments. Another approach is to utilize corrosion inhibitors, which are chemicals added to the concrete mix or applied directly to the steel surface. These inhibitors form a protective layer around the rebars, preventing corrosive agents from reaching the steel and slowing down the corrosion process. Additionally, proper concrete cover thickness should be maintained to ensure rebars are adequately protected from exposure to corrosive elements. Adequate concrete cover acts as a barrier, preventing moisture and other corrosive agents from reaching the steel. Regular inspection and maintenance are crucial to identify any signs of corrosion early on. If corrosion is detected, appropriate measures should be taken to repair or replace the affected rebars to maintain the structural integrity of the project. In summary, while steel rebars can be used in corrosive environments, it is essential to consider the specific conditions and employ the appropriate strategies to protect against corrosion. By using corrosion-resistant materials, applying inhibitors, maintaining proper concrete cover, and conducting regular inspections, the lifespan and performance of steel rebars in corrosive environments can be significantly enhanced.

- Q: Can steel rebars be used in solar power plant construction?

- Steel rebars are a viable option for incorporating into the construction of solar power plants. In the construction industry, steel rebars are frequently utilized to reinforce concrete structures. This is particularly relevant for solar power plants, as concrete foundations are typically necessary for installing solar panels and other equipment. By implementing steel rebars in these foundations, the structural integrity and durability of the solar power plant infrastructure can be ensured. Moreover, steel rebars possess corrosion-resistant qualities, which are especially valuable in solar power plant construction due to their exposure to a variety of weather conditions. All in all, steel rebars serve as a suitable material for reinforcing concrete structures in the construction of solar power plants.

- Q: How do steel rebars contribute to the crack control in slabs and walls?

- The resistive properties of steel rebars contribute significantly to crack control in slabs and walls. When loads are applied to concrete slabs and walls, such as the weight of the structure or external forces, they can develop tensile stresses. However, concrete is strong in compression but weak in tension, which makes it susceptible to cracking under tensile forces. To counteract these tensile stresses, steel rebars are embedded within the concrete. The rebars absorb and distribute the tensile forces, preventing crack formation and controlling their propagation. Essentially, the rebars act as reinforcement, enhancing the overall tensile strength of the concrete. The presence of steel rebars in slabs and walls has the additional benefit of limiting the width and length of cracks that may occur. This is achieved by providing resistance against the tensile stresses. This crack control is of utmost importance in maintaining the structural integrity and durability of the concrete elements. Moreover, steel rebars also contribute to crack control by enhancing the overall ductility of the structure. Ductility refers to the ability of a material to deform under load without fracturing. By improving the ductility of the concrete, the rebars enable the structure to absorb energy and deform in a controlled manner. This reduces the likelihood of sudden failure or catastrophic collapse. In conclusion, steel rebars play a crucial role in crack control in slabs and walls. They increase the tensile strength of concrete, limit crack width and length, and improve overall structural ductility. Their presence ensures the long-term durability and safety of these concrete elements.

- Q: Can steel rebars be used in high-strength concrete?

- Yes, steel rebars can be used in high-strength concrete. In fact, steel rebars are commonly used to reinforce concrete structures, regardless of the concrete strength. High-strength concrete refers to concrete that has a compressive strength significantly higher than conventional concrete. It typically has a compressive strength of 6,000 psi (pounds per square inch) or more. Steel rebars are essential in high-strength concrete to provide the necessary tensile strength. While concrete has excellent compressive strength, it is relatively weak in tension. By incorporating steel rebars into the concrete, the composite material becomes stronger and more durable. The rebars act as reinforcement, resisting the tensile forces and preventing cracks or failure in the structure. However, it is important to note that the selection of the appropriate steel rebar for high-strength concrete is crucial. The rebars used should have sufficient strength and ductility to withstand the higher stresses and strains associated with high-strength concrete. Additionally, proper placement, spacing, and anchorage of the rebars are essential to ensure effective reinforcement and optimal performance of the concrete structure. In summary, steel rebars can definitely be used in high-strength concrete to enhance its tensile strength and overall structural integrity.

- Q: What is the weight of a typical steel rebar?

- The weight of a typical steel rebar can vary depending on its size and length. On average, a 1-inch diameter, 20-foot long steel rebar weighs around 13.6 pounds.

- Q: What is the process of deforming steel rebars for better adhesion with concrete?

- The process of deforming steel rebars for better adhesion with concrete is known as ribbing or rib formation. It involves creating a series of ribs or deformations along the surface of the rebars to increase their surface area and improve the bond strength between the steel and concrete. This is typically achieved by passing the rebars through a specialized machine that uses rollers or dies to shape the desired rib pattern. The resulting ribbed rebars provide enhanced mechanical interlocking with the concrete, ensuring a stronger and more durable bond in reinforced concrete structures.

- Q: Can steel rebars be used in industrial flooring?

- Industrial flooring can indeed incorporate steel rebars, as they possess remarkable tensile strength and durability. The incorporation of steel rebars in concrete construction, particularly in industrial flooring, is a widespread practice. These rebars are strategically positioned within the concrete to reinforce it and provide additional strength, enabling it to withstand heavy loads and prevent cracking. By utilizing steel rebars in industrial flooring, the capacity to bear weight is significantly augmented, and the floor's longevity and structural integrity are assured. Furthermore, steel rebars can be effortlessly welded or linked together to form a grid or mesh, further enhancing the floor's strength and stability. Hence, steel rebars are a suitable choice for industrial flooring applications.

Send your message to us

Eleven mm Cold Rolled Steel Rebars with High Quality

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 15000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords