Electrolytic Tin Plate Coils and Sheets for Chemical Metal Packaging

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Structure of Electrolytic Tin Plate Coils and Sheets for Chemical Metal Packaging Description

Due to Tinplate packaging`s good seal, nature, dark, robustness and unique decorative metal charm, it has a wide range of coverage in the packaging container industry,and common international packaging varieties. With a variety of CC tinplate material, DR materials, chrome plated and constantly enrich and promotion and development of packaging products and technology, tinplate packaging has promoted with innovation.

Because of its strong antioxidant and diverse styles, printed, tinplate containers are very popular and loved by customers, and they are widely used in food packaging, pharmaceutical packaging, commodity packaging, instrumentation, packaging, industrial packaging and so on.

With the continuous improvement of tinplate printing technology and processing technology, tinplate packaging has developed more widely.

2.Main Features of the Electrolytic Tin Plate Coils and Sheets for Chemical Metal Packaging

Appearance – Electrolytic Tin Plate is characterized by its beautiful metallic luster. Products with various kinds of surface roughness are produced by selecting the surface finish of the substrate steel sheet.

Paintability and printability – Electrolytic Tin Plates have excellent paintability and printability. Printing is beautifully finished using various lacquers and inks.

Formability and strength – Electrolytic Tin Plates have got very good formability and strength. By selecting a proper temper grade, appropriate formability is obtained for different applications as well as the required strength after forming.

Solderability and weldability – Electrolytic Tin Plates can be joined both by soldering or welding. These properties of tinplate are used for making various types of cans.

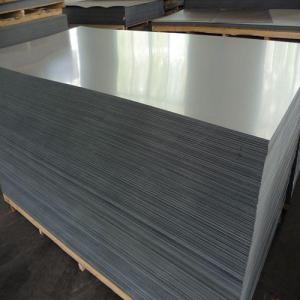

3.Electrolytic Tin Plate Coils and Sheets for Chemical Metal Packaging Images

4.Electrolytic Tin Plate Coils and Sheets for Chemical Metal Packaging Specification

Standard | ISO 11949 -1995, GB/T2520-2000,JIS G3303,ASTM A623, BS EN 10202

|

Material | MR,SPCC |

Thickness | 0.15mm - 0.50mm |

Width | 600mm -1150mm |

Temper | T1-T5 |

Annealing | BA & CA |

Coil Inner Diameter | 508mm |

Weight | 6-10 tons/coil 1~1.7 tons/sheets bundle |

Passivation | 311 |

Oil | DOS |

Surface | Finish,bright,stone,matte,silver |

5.FAQ of Electrolytic Tin Plate Coils and Sheets for Chemical Metal Packaging

-How to place .an order or contact you ?

Please send us Email. we will give you a quick response in seconds .

- How is your quality ?

All our quality is prime even the secondary quality . We have many years experience

In this field with serious quality control standard . Advanced equipment, We welcome your visit to our factory .

- Q: How does tinplate contribute to the overall protection of packaged products?

- Tinplate contributes to the overall protection of packaged products by providing a strong and durable barrier against external elements such as moisture, light, and air. It helps to prevent corrosion, contamination, and spoilage, thereby extending the shelf life of the packaged products. Additionally, tinplate's resistance to impact and tampering ensures the integrity of the package, safeguarding the contents during transportation and handling.

- Q: Can tinplate be customized with different designs or logos?

- Yes, tinplate can be easily customized with different designs or logos. Its smooth surface allows for high-quality printing, making it an ideal choice for branding and promotional purposes.

- Q: How does tinplate contribute to the protection of textile products?

- Tinplate contributes to the protection of textile products by providing a durable and corrosion-resistant packaging material. It acts as a barrier against moisture, oxygen, and light, preventing damage and preserving the quality of the textile products during storage and transportation. Additionally, tinplate's strength and rigidity offer added protection against physical impacts and external forces, safeguarding the integrity of the textile items.

- Q: What are the advantages of using tinplate for cosmetic packaging?

- There are several advantages of using tinplate for cosmetic packaging. First, tinplate is highly durable and provides excellent protection to the cosmetic products, ensuring their integrity during transportation and handling. Second, tinplate is resistant to corrosion and can withstand moisture, which is crucial for preserving the quality and shelf life of cosmetics. Third, tinplate is a sustainable packaging option as it is 100% recyclable and can be reused multiple times, reducing the environmental impact. Lastly, tinplate offers a premium and attractive appearance, enhancing the overall aesthetic appeal of cosmetic packaging and leaving a positive impression on consumers.

- Q: How to distinguish galvanized plate and tin plate

- From the outside, hot galvanized, electro galvanized tin plate surface is rough, thick tin layer of light and bright, thin tin layer, hot galvanized galvanized is not only the contest, Matt

- Q: What are the different methods of reusing tinplate packaging?

- There are several ways to reuse tinplate packaging. One common method is to repurpose the packaging for storing small items like buttons, jewelry, or crafting supplies. Tinplate packaging can also be used as decorative containers for plants, candles, or as unique gift boxes. Additionally, tinplate packaging can be recycled and used to create new products, reducing waste and promoting sustainability.

- Q: How does tinplate packaging contribute to product visibility?

- Tinplate packaging enhances product visibility by providing a sleek and reflective surface that attracts attention and highlights the product's branding and design. The shiny nature of tinplate packaging helps products stand out on store shelves, making them more noticeable and appealing to customers.

- Q: How is tinplate used in the manufacturing of kitchenware?

- Tinplate is commonly used in the manufacturing of kitchenware due to its excellent corrosion resistance and its ability to preserve the flavor and freshness of food. It is often used to create canisters, containers, and food packaging, providing a protective layer that prevents contact between the metal and the food. Tinplate also offers an attractive and shiny appearance, making it a popular choice for the production of kitchen utensils like cookware, cutlery, and baking trays.

- Q: How is tinplate affected by extreme temperatures?

- Tinplate is generally resistant to extreme temperatures and can withstand both high and low temperatures without significant changes in its properties.

- Q: How does tinplate contribute to the circular economy in the steel industry?

- Tinplate contributes to the circular economy in the steel industry by being a highly recyclable material. It can be easily separated from other materials during the recycling process and reused multiple times without losing its properties. This promotes resource efficiency and reduces the need for new raw materials, ultimately reducing waste and environmental impact. Additionally, tinplate's durability and corrosion resistance make it suitable for long-term use, further extending its lifecycle and contributing to a sustainable steel industry.

Send your message to us

Electrolytic Tin Plate Coils and Sheets for Chemical Metal Packaging

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords