Electric hoist 10ton

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Introduction

CD or MD type wire rope electric hoist is a kind of light type lifting equipment. It could be installed on single girder crane with hoist, overhead,gantry and jib crane. Modified could be used as a winch. So it is a commonly used lifting equipment in factory, mine, port, warehouse, cargo yard, shop etc, is a nessesary equipment to improve working efficiency and labor conditions.

2. Technical parameter

Model | CD1 MD1 | |||||||||||||||||||||||

Capacity | t | 5 | 10 | |||||||||||||||||||||

Lift height | m | 6 | 9 | 12 | 18 | 24 | 30 | 6 | 9 | 12 | 18 | 24 | 30 | |||||||||||

Lift speed | m/min | 8, 0.8/8 | 8, 0.8/8 | |||||||||||||||||||||

Travel speed | m/min | 20 | 20 | |||||||||||||||||||||

Wire rope | nominal diameter | mm | 14 | 14 | ||||||||||||||||||||

Structure | 6×37+NF | 6×37+NF | ||||||||||||||||||||||

Traveling track GB/T706-1988 | 28a~63c | 28a~63c | ||||||||||||||||||||||

Min curvature radius | m | 2.5 | 3 | 4 | 5 | 2.5 | 3.5 | 4 | 6 | 7.5 | 9 | |||||||||||||

Hoist moto | Model | ZD1 41-4 ZDS1 0.8/7.5 | ZD1 51-6 ZDS1 1.5/13 | |||||||||||||||||||||

Power | KW | 7.5, 0.8/7.5 | 13,1.5/13 | |||||||||||||||||||||

Rpm | r/min | 1380 | 930 | |||||||||||||||||||||

Trolley motor | Model | ZDM1 12-4F1 | ZDM1 12-4F1 | |||||||||||||||||||||

Power | KG | 0.5 | 0.5×2 | |||||||||||||||||||||

Rpm | r/min | 1380 | 1380 | |||||||||||||||||||||

Bonding times | T/H | 120 | 120 | |||||||||||||||||||||

Work duty |

| M3 | M3 | |||||||||||||||||||||

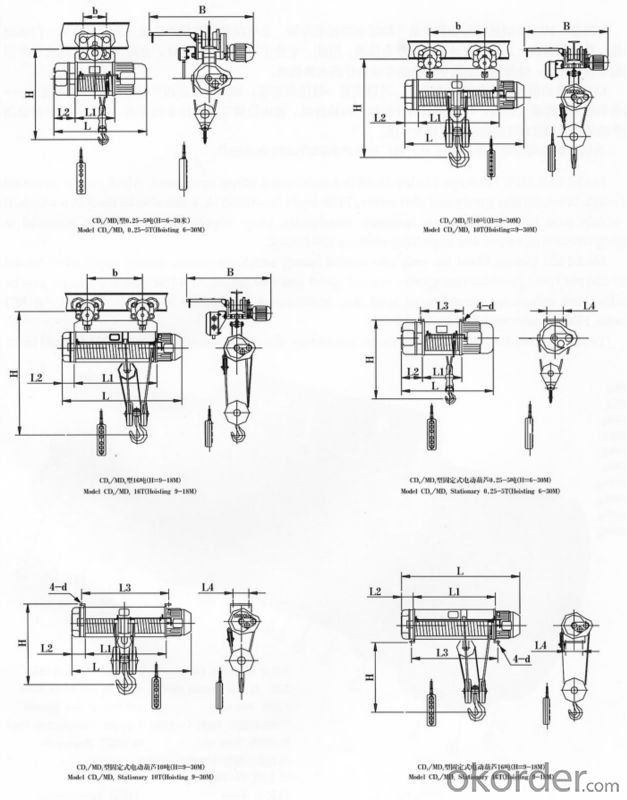

3.Sketch

- Q: What does the working grade A1A8 mean

- In order to be safe, crane is used for crane operation. Crane working grade Crane work level (gb3811-83) is classified according to crane utilization rating and load condition. Crane use grade The use level is the frequency of the use of the crane in its effective life, and the total number of work cycles is N According to the total number of cycles, the crane is divided into U0 ~ U910. Table 2 is the crane utilization scale. Table 2 crane utilization level Use the rank total work cycle N notes

- Q: How is the crane on the construction site built

- When working in the basement, it will be installed, at this time, it will be a general mobile crane, a piece of combination. Inside the tower, there is a hydraulic jack, which is used as a climb. When the building is covered by a layer, the height has to reach the tower, and the climb is done. Fixed tower crane tower crane engineer will screw loosening, jack, will cranes rise about one meter, then pillar fixed on the structure of the building, and then narrowed jack and will be at the bottom of the fixed on the building structure, and loosen the upper screw, hold up a jack, rose again one meter, so repeatedly, backwards, a stretched to the desired height, then pillar is fixed.

- Q: Does the electric single-beam crane electric hoist operation need operation certificate?

- Need to handle, by trained personnel operations, but generally not strictly implemented, a crane need at least one certificate, and to the technical supervision administration for registration.

- Q: What is an insulated bridge crane

- Insulated bridge cranes are often used in the electrolytic workshop. Because the weight of the lifting is charged, to prevent the current from passing through the crane metal and the driver and the damaged equipment

- Q: Which parts should the protective plate of the bridge crane be set in?

- (3) the sliding line of the lower crane should be set up the protective plate along the length of the bridge crane.

- Q: What should the crane driver do when the accident occurred

- A first put suspended objects in a safe place, the second is the crane stopped electricity, 3 it is report to superior, four is cooperate to rescue the injured, five is to protect the scene.

- Q: Details of several anti-rolling systems of the tyrotype container gantry crane?

- Hydraulic pressure stabilizer 2 1 stabilizer of stabilizer by drum roll reduction, stabilization, reversing the pulleys and transition pulley, wire rope of the hydraulic cylinder and a set of hydraulic system. The roll-down drum is driven by an open-type gear through an open gear, and it is operated in synchrony. The hydraulic cylinder is placed on the shelf, and the hydraulic cylinder pressure is provided by a hydraulic unit that is also placed on the shelf. The hydraulic system is composed of the following five parts: from the hoisting device to the oil outlet, the control valve block of the hydraulic valve, the pressure switch and the four hydraulic pressure hydraulic system. 30?? # crane transport machinery?? 2007 (6) cylinder, hydraulic accumulator and safety module.

- Q: How many times does the crane take every year?

- Special equipment including boilers, pressure vessels (including gas cylinders), pressure pipes, elevators, lifting machinery, motor vehicles for field (factory), a large-scale amusement facilities, passenger ropeway, they all different periodic inspection cycle. The periodic inspection cycle of crane machinery is usually two years.

- Q: The lifting machinery for the first inspection is also used without regular inspection

- First, which have no implementation included in the catalog of special equipment installation inspection and in the form of the whole machine factory, direct delivery unit using hoisting machinery, by the local inspection before use registration examination organization on the basis of special equipment safety inspection items and their contents and methods of the relevant rules and regulations of inspection (that is, the equipment put into use before the test). Registration will be registered after the first check.

- Q: Several categories of tower crane

- Crane (Crane) is a kind of Crane machine, which is a kind of mechanism for circulation and intermittent motion. A work cycle including: fetch up the items from the fetch, lowered level and then move to the designated place, then reverse movement, to return the fetch device in situ, for the next cycle.

Send your message to us

Electric hoist 10ton

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches