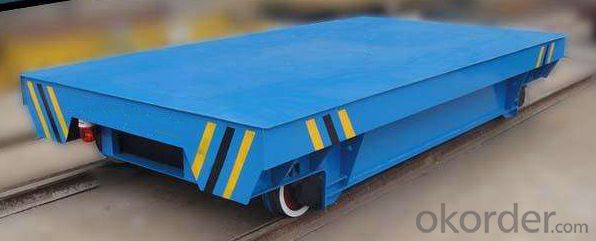

Electric Flat Car,Electric Rail Car,Trolley

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 100 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Profile

Electric flat car is an electric rail transport vehicle.Also known as trolley, cross vehicle.It has the advantages of simple structure, convenient use, easy maintenance, large bearing capacity, less pollution and so on.Widely used in machinery manufacturing and metallurgy factory, as the workshop internal coordination crane transport heavy cross in.

Technical Parameters

The most of electric flat car is reel power supply for electric flat car, with a cable reel 380V AC power supply.Cable reel for hysteresis coupling, ensure the uniform stress of the cable is not easy bad.The exchange of 380V to flatcar YZ metallurgy Lifting motor provides power, electric flat car operation.Flat car running cable reel automatic cable rolled up or release, by the reel power supply length effects, general maximum operating distance is less than 200m. The single-phase 36V (three-phase) low-voltage track power supply electric flat car, rail sliding contact line power supply.Ground step-down transformer control cabinet (three-phase AC single-phase) 380V buck to single phase (phase 36V), via rail sliding contact line is fed to a flat car, the car a step-up transformer for single phase (phase 380V) AC.For flat cars in single phase capacitor motor provides power (three YZ metallurgy Lifting motor).Because there is no cable, it is safe and reliable, not afraid of hot, not hit, do not prevent cross transport, easy to realize the remote control and automation, transportation arrangement with great convenience to the factory.But the track construction requirements higher, should ensure that the track insulation, over a certain distance running track should be added to copper compensation line.Running distance is longer also need to increase the number of voltage transformer.

The electric flat car starting through the track starting current is very large (up to 1000A), at the end of the track has a large voltage drop, caused by single phase capacitor motor starting difficulty, the single-phase flatcar maximum tonnage is 50 tons, load 50 tons and above using three-phase 3

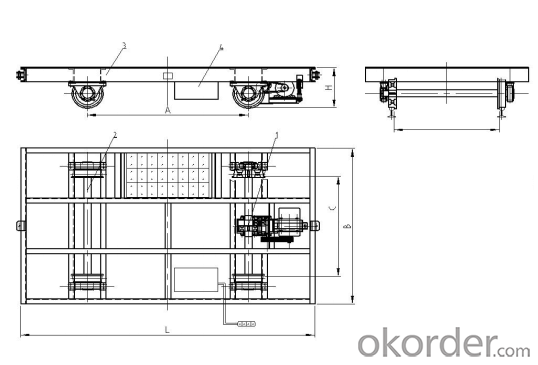

Structure

-General

The electric flat car mainly consist of frame, transmission device (active, passive wheel wheel), electrical control.

Frame with four longitudinal beams and a plurality of beams and decking plate welded into a frame structure, usually with large steel as frame longitudinal beam, bearing frame, take eight, uniform stress.Wheel-set on the shoulder pole bearing seat is connected with the frame by bolts, the structure effectively reduces the height of table.

Gear reducer cycloidal type gear reducer on the flat end, convenient assembly and maintenance, convenient refit.

Electric flat car and set up a connection hook, when necessary, can draw other cars or be towed.Flat car for lifting the lifting holes arranged on both sides.Mode of operation for the use of a hand held button box walking vehicle control.

-Wheel

The wheel and axle of the electric flat car is arranged between the inner and outer insulating sleeve and the insulating pad, the insulating sleeve with high mechanical properties of insulating materials made from nylon, wheel after insulation makes the electric flat car can use two tracks as a two conductor rail.Axle material for the 45 # steel quenched and tempered, wheel material using 55 high quality steel, surface quenching, bearings are double-row spherical roller bearings, can automatically compensate the deformation of frame error.

Wheel bearing seat through the pole mounted on the frame, each side with four fixing bolt, the structure effectively reduces the height, lateral stability, bearing capacity, stress of a frame beneficial.

-Transmission Device

The transmission form of the electric flat car as a V belt deceleration with a two gear reducer.The motor through a triangular V belt transmission two stage gear reducer, reducer high speed motor is fixed on the body side, by tension bolt and tension belt.

Speed reducer for flat car special axle-hung hardened-gear speed reducer, the output shaft is driving wheel axle, gear for hardened gear, has the advantages of small volume, large transmission power, good fatigue strength.Gear material pinion 40 Cr, 20Cr.Speed reducer and the driving wheel set is composed of a transmission device assembly.Through the pole bearing block is mounted on the frame, each side with four bolts to fix.

-Traction Hook

Electric flat car and set up a connection hook, when necessary, can draw other cars or be towed.Pay special attention to when the car is towed, be sure to lift the brake, to prevent gear or triangle V belt damage.And do not exceed the rated speed of flat, otherwise the motor for super rotation state which could damage.

- Q: What is the proof of working in mechanical design?

- The mechanical engineer qualification exam outline (trial) is the Chinese mechanical engineering society, the ministry of education test center for mechanical engineering and technical personnel in our country one of technical qualification certification exam standards documents. It is a mechanical engineer declarant qualification to participate in "comprehensive qualities and skills" the basis of a review test for reference, is to write "mechanical engineer qualification examination instruction" and so on the basis of learning materials, is carried out around the student counseling on the basis of, is the basis of a qualification examination proposition. This outline is divided into four parts: Ⅰ. Basic requirements, Ⅱ. Exam content, Ⅲ. Regulations and instructions, Ⅳ. Sample questions example. Basic requirements part aims to show that as a qualified mechanical engineer, should actively adapt to the world manufacturing industry globalization, informationization, greening and the trend of the development of the service, strive to improve their own comprehensive quality, become a good professional ethics and innovation concept, master machinery manufacturing technology, understand the economic and management knowledge as well as the relevant international rules of a new generation of mechanical engineering and technical personnel.

- Q: What are the potential defects of the automated material handling system?

- In manufacturing and material handling, the automatic pilot (AGV) has become increasingly familiar. But the shuttle, which is introduced here, is based on the equipment that automatically carries the material in the path of the orbit. Machine commonly used in existent shelves, existent shelves for its high space utilization, accepted by a lot of storage and transportation unit, but forklift truck into the tunnel, because the space is narrow, there are shelves safe hidden trouble. In addition, using forklift and human handling inefficient, high cost, on the basis of the original shelves introducing automation machine, in order to improve the automatization level of the whole line production storage and transportation.

- Q: What is the rational and scientific classification of logistics facilities and equipment

- Facilities: like warehouses, roads, public parking lots and so on. Equipment: vehicles, pallets, forklifts, RF scanners, GPS locators, and so on. Large and long-term use and investment, not easy to move and sell are facilities.

- Q: The wear-resisting parts in the broken machine are mainly the direct contact with the material

- There is a need to contact, the crusher is a lot of model and the performance is different. For example: the jaw is broken, the hammer is broken, the fight is broken, the cone is broken... It is. Wear-resisting material is different also, also need according to the material hardness, strength of the material that is broken, the choice is ok. Materials: alloy white iron (high chromium cast iron), high manganese steel, alloy steel (high, medium, low carbon and alloy)... It is. It's best to find experienced manufacturers. Hope to adopt.

- Q: The development of material handling

- Domestic market competition is the basic material handling machinery, high-end market is mainly composed of multinational companies, domestic key large enterprise also had some markets in some specific fields; The participants in the mid-market market include large enterprises in China and small and medium-sized enterprises with excellent manufacturing technology and high management level. Many of the small scale, poor technology, poor management, lack of product innovation of enterprise, product quality is not high, low added value, poor economic benefit, in the industry of low-end market, competition is intense. "Twelfth five-year" period to 2020, is China's national economy sustainable development strategy implement and promote the development of circular economy, take a new road to industrialization, the basis for building a resource-conserving and environment-friendly society an important period. Attaches great importance to the society and the enterprise logistics role, vigorously develop modern logistics industry, to promote the development of and promote industry, improve the quality and efficiency of economic operation, enhance the comprehensive national strength and the enterprise competitiveness, has the very vital significance. It is an effective means of carrier for all walks of life of the national economy, including the manufacturing of material handling equipment which supplies the large amount of equipment needed for the second and third industries. The rapid and steady development of the national economy, the informationization and industrialization of the basic industries, provide the best opportunities for the manufacturing industry of materials handling equipment.

- Q: The beneficial effect of material handling machinery

- Material handling machinery is serving the production, its design and type selection should be subject to the needs of the production process, new material handling machinery but also often leads to the change and improvement of the manufacturing process. For example, the emergence of bucket wheel stacker reclaimer, formed the bucket wheel stacker reclaimer for heart, belt conveyor for blood vessels, the electronic computer is the nerve center of automation of large bulk material handling system, which changes the ports, mines and the layout of the power plant and so on of the bulk yard; It can simplify the structure of the factory and reduce the cost of construction.

- Q: Material handling system in the factory

- The machinery factory's internal logistics system involves the production plan, process flow, moving operation, warehouse management, information system and so on.

- Q: The principle of material handling

- The principle of the effectiveness of the handling operation: the cost of carrying the unit to determine the performance of the transport. Safety principle: provide proper means and equipment to enhance handling safety.

- Q: What is the carrying equipment of the container cargo

- Container (container), crane, forklift truck Kunshan city peng a lift lifting transportation and handling professional clean room equipment installation, precision air handling import and export container, unpacking, assembling positioning, whole factory move, special lifting engineering contracting, precision machine packed in wooden cases

- Q: There are three things to do when the material is stacked up and down

- Fire prevention, waterproof, and do not exceed the limit.I hope my answer will help you.

Send your message to us

Electric Flat Car,Electric Rail Car,Trolley

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 100 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords