ductile iron pipe k7 DN600 Socket Spigot pipe

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1) The standard of pipe: ISO2531:1998, EN545:2006,K9 K8

2) Effective length: 6m/5.7m

3) Inner cement line: Portland cement lineas per ISO4179

4) Zinc coating: at least 130g/m2 as per ISO8179

5) Bitumen painting: at least 70μm as per ISO8179

6)With 102% quantity of NBR, SBR, or EPDM ring asper ISO4633

7) DN80-DN1200

8) Highstrength, lighter than grey iron, good corrosion resistance, no furring, smallflow resistance, easy fixing, long life tome about 100 yeas

9)Checked by automatic inspection equipment

10) Composition:

Chemical composition | |||

Chemical composition | Ductile Cast Iron Pipe (%) | Grey iron pipe (%) | Steel pipe (%) |

C | 3.5-4.0 | 3.2-3.8 | 0.1-0.2 |

Si | 1.9-2.6 | 1.4-2.2 | 0.15-0.4 |

Mn | 0.15-0.45 | 0.4-0.6 | 0.3-0.6 |

P | ≤0.06 | ≤0.3 | 0.02-0.03 |

S | ≤0.02 | ≤0.1 | 0.02-0.03 |

Mg | 0.03-0.06 |

|

|

11) Feature:

Mechanical properties | |||

| Ductile Cast Iron Pipe | Grey Iron Pipe | Steel Pipe |

Tensile Strength(Mpa) | ≥420 | 150-260 | ≥400 |

Yield Strength(Mpa) | ≥300 | No Confirmation | No Confirmation |

Bending Strength(Mpa) | ≥590 | 200-360 | ≥400 |

Elongation (%) | ≥10 | Neglected | ≥18 |

Brinell Hardness(HBS) | ≤230 | ≤230 | About 140 |

12) T type mechanical joint

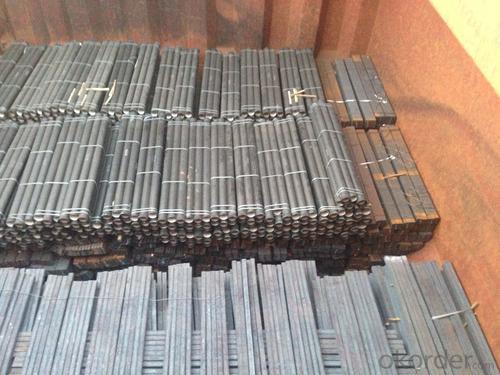

13) Packing: in bulk or container

PACKING: 1) Pipesare bundled together with the steel belt.

2) Wooden pieces are put between the pipes.

- Q: What are the different types of coatings available for ductile iron pipe?

- There are several different types of coatings available for ductile iron pipe, each with unique properties and advantages. 1. Cement Mortar Coating: This is a commonly used coating for ductile iron pipe. It involves applying a layer of cement mortar to the interior and exterior surfaces of the pipe. This coating provides protection against corrosion and abrasion, as well as improving the hydraulic efficiency of the pipe. 2. Polyethylene Encasement: Another popular coating for ductile iron pipe is polyethylene encasement. This involves wrapping the pipe with a layer of polyethylene material. This coating provides excellent corrosion resistance and is particularly effective in protecting against soil and water contaminants. 3. Fusion-Bonded Epoxy (FBE) Coating: FBE coating involves applying a layer of epoxy powder to the pipe surface, which is then heated to create a strong bond. This coating provides excellent corrosion resistance and is commonly used in aggressive environments such as wastewater treatment plants and chemical processing facilities. 4. Zinc Coating: Zinc coating, also known as galvanization, involves applying a layer of zinc to the surface of the ductile iron pipe. This coating provides excellent corrosion resistance and is often used in outdoor applications where the pipe is exposed to moisture and humidity. 5. Bituminous Coating: Bituminous coating is a black, tar-like substance that is applied to the surface of the pipe. It provides protection against corrosion and is commonly used in underground applications where the pipe is in contact with soil or water. 6. Polyurethane Coating: Polyurethane coatings provide excellent resistance to abrasion, impact, and chemical corrosion. They are often used in aggressive environments such as oil and gas pipelines. These are just a few examples of the different types of coatings available for ductile iron pipe. The choice of coating depends on factors such as the intended application, environmental conditions, and the level of corrosion protection required. It is important to consult with industry experts and adhere to relevant standards and specifications when selecting a coating for ductile iron pipe.

- Q: How does ductile iron pipe handle temperature changes?

- Ductile iron pipe is known for its ability to handle temperature changes effectively. The unique properties of ductile iron make it highly resistant to thermal expansion and contraction, allowing it to withstand extreme temperature variations without significant deformations or failures. When exposed to temperature changes, ductile iron pipes can expand or contract within certain limits due to its inherent ductility. This flexibility helps to accommodate thermal stresses and prevent the pipe from cracking or breaking. The material's high tensile strength and elasticity also contribute to its ability to handle temperature changes without significant structural damage. Moreover, ductile iron pipes have a low coefficient of thermal expansion, meaning they expand and contract at a relatively slow rate compared to other materials. This characteristic minimizes the potential for stress on the pipe joints and reduces the risk of leaks or failures. In addition to its excellent thermal stability, ductile iron pipe also features a protective lining that further enhances its resistance to temperature changes. The linings, such as cement mortar or polyethylene, create a barrier between the pipe and the transported fluid, preventing any adverse effects caused by thermal variations on the pipe's internal surface. Overall, ductile iron pipe is a reliable choice for applications where temperature changes are common. Its ability to withstand thermal stresses, low coefficient of thermal expansion, and protective linings make it a durable and efficient solution for various infrastructural needs, including water distribution, wastewater management, and industrial applications.

- Q: Can ductile iron pipes be used for stormwater management systems?

- Yes, ductile iron pipes can be used for stormwater management systems. Ductile iron pipes are known for their strength, durability, and corrosion resistance, making them suitable for handling stormwater runoff. They can effectively transport large volumes of water and withstand the pressure and impact associated with stormwater management.

- Q: How many degrees can the ductile iron pipe be each?

- Minimum tensile strength: 420/Mpa, minimum yield strength: 300/Mpa, minimum elongation 7%.

- Q: How is ductile iron different from cast iron?

- Ductile iron and cast iron are two types of iron alloys that differ in terms of their composition, properties, and applications. The main difference between ductile iron and cast iron lies in their microstructure and mechanical properties. Ductile iron, also known as nodular cast iron or spheroidal graphite iron, is a type of cast iron that undergoes an additional treatment process to enhance its strength and ductility. This is achieved by adding small amounts of magnesium to the molten iron during the casting process, which results in the formation of graphite nodules throughout the material. These graphite nodules act as stress raisers and prevent the propagation of cracks, making ductile iron more resistant to fractures and providing it with improved ductility compared to cast iron. In contrast, cast iron is a type of iron alloy that contains a higher carbon content than ductile iron. This higher carbon content leads to the formation of graphite flakes within the material, giving cast iron its characteristic brittle nature. Due to its brittleness, cast iron is more prone to cracking and less flexible than ductile iron. However, cast iron has excellent compressive strength and is highly resistant to wear and abrasion, making it suitable for applications where strength and durability are important, such as in engine blocks, pipes, and manhole covers. Another difference between ductile iron and cast iron is their machinability. Ductile iron is generally easier to machine due to its lower carbon content and the presence of graphite nodules, which act as lubricants during the cutting process. On the other hand, the presence of graphite flakes in cast iron can cause tool wear and result in poor surface finish during machining. In summary, ductile iron and cast iron differ in their microstructure, mechanical properties, and applications. Ductile iron offers improved ductility and resistance to fractures, making it suitable for applications requiring flexibility and impact resistance. Cast iron, with its higher carbon content and graphite flakes, provides excellent compressive strength and wear resistance, making it ideal for applications requiring strength and durability.

- Q: Are ductile iron pipes recyclable?

- Yes, ductile iron pipes are recyclable. Ductile iron is a type of cast iron that has superior strength and durability, making it an excellent choice for various applications, including water and sewage systems. When these pipes reach the end of their lifespan, they can be recycled and reused. The recycling process involves melting down the ductile iron pipes and using the molten metal to produce new pipes or other iron-based products. Recycling ductile iron pipes not only helps to conserve natural resources but also reduces the amount of waste that goes into landfills. Therefore, ductile iron pipes are considered a sustainable and environmentally friendly option for piping systems.

- Q: How do ductile iron pipes handle cyclic loading in offshore applications?

- Ductile iron pipes are known for their exceptional strength and durability, making them a suitable choice for various applications, including offshore use. When it comes to handling cyclic loading in offshore environments, ductile iron pipes have several characteristics that contribute to their performance. Firstly, ductile iron pipes have a high resistance to fatigue failure. Fatigue failure occurs when a material experiences repeated cycles of stress, which can cause cracks to initiate and propagate over time. Ductile iron pipes are designed to withstand cyclic loading without compromising their structural integrity, thanks to their inherent ductility and ability to absorb and distribute stress effectively. Additionally, ductile iron pipes possess excellent impact resistance. Offshore environments are prone to dynamic and unpredictable forces, such as waves and currents, which can exert sudden and high impact loads on the pipes. The high impact resistance of ductile iron allows it to withstand these forces without deformation or fracture, ensuring the pipes remain intact and functional. Moreover, ductile iron pipes have a unique microstructure that enables them to resist corrosion. Offshore applications expose pipes to harsh environmental conditions, including saltwater, which can accelerate the corrosion process. However, the protective graphite matrix in ductile iron pipes acts as a barrier, preventing corrosive agents from reaching the underlying metal and significantly extending the pipes' service life. Furthermore, ductile iron pipes have a high load-carrying capacity. In offshore applications, pipes often need to support heavy loads, such as those from equipment, structures, or seabed settlements. Ductile iron's superior strength allows it to bear these loads effectively, maintaining the structural integrity and stability of the system. Lastly, ductile iron pipes offer ease of installation and maintenance. Their lightweight nature makes them easier to handle and transport during offshore operations. Additionally, their corrosion resistance minimizes the need for frequent maintenance, reducing downtime and costs associated with repairs and replacements. In conclusion, ductile iron pipes exhibit excellent performance in handling cyclic loading in offshore applications. Their resistance to fatigue failure, impact resistance, corrosion resistance, high load-carrying capacity, and ease of installation and maintenance make them a reliable and efficient choice for offshore environments.

- Q: Luo what effect of ductile cast iron

- Chromium can improve the hardness, strength and wear resistance of nodular iron, and increase bainite in bainite ductile iron.

- Q: Can ductile iron pipes be used for irrigation of golf courses?

- Yes, ductile iron pipes can be used for irrigation of golf courses. Ductile iron pipes are known for their durability, strength, and resistance to corrosion, making them suitable for various applications, including irrigation systems. They can withstand high-pressure water flow and are less likely to crack or break compared to other materials. Additionally, ductile iron pipes have a longer lifespan, reducing the need for frequent maintenance or replacement. Therefore, they are a reliable choice for irrigating golf courses, where a consistent and efficient water supply is crucial for maintaining healthy turf and landscaping.

- Q: Can ductile iron pipes be used for underground chemical transport systems?

- Ductile iron pipes are commonly used for various applications due to their strength, durability, and resistance to corrosion. However, when it comes to underground chemical transport systems, there are certain factors that need to be considered before choosing ductile iron pipes as the suitable material. Firstly, the type of chemicals being transported should be evaluated. Ductile iron pipes are generally resistant to a wide range of chemicals, including acids, alkalis, and organic solvents. However, there are some chemicals that can corrode or react with the iron content of the pipes, leading to degradation and potential leakage. Therefore, it is crucial to assess the chemical compatibility and consult with chemical engineers or experts to determine whether ductile iron pipes are suitable for specific chemical transport applications. Secondly, the concentration and temperature of the chemicals should be taken into account. Elevated temperatures and high concentrations of certain chemicals can accelerate the corrosion process, potentially compromising the integrity of the pipes. It is essential to assess the operating conditions and ensure that the ductile iron pipes can withstand the chemical concentration and temperature levels. Additionally, the potential presence of abrasive or erosive chemicals should be considered. If the transported chemicals contain abrasive particles or have erosive properties, it may lead to increased wear and tear on the inner surface of the pipes, reducing their lifespan and potentially causing leaks. In such cases, alternative materials with higher resistance to abrasion or erosion may be more suitable. Lastly, it is important to comply with relevant regulations and standards. Different countries or regions may have specific requirements for underground chemical transport systems, including the choice of materials. It is necessary to ensure that ductile iron pipes meet the necessary standards and are approved for use in such applications. In conclusion, while ductile iron pipes have many desirable properties for various applications, including underground use, their suitability for chemical transport systems depends on several factors. Chemical compatibility, concentration and temperature levels, the presence of abrasive or erosive chemicals, and compliance with regulations should all be carefully evaluated before deciding to use ductile iron pipes for underground chemical transport systems. Consulting with experts in the field is highly recommended to ensure the safety and effectiveness of the chosen piping material.

Send your message to us

ductile iron pipe k7 DN600 Socket Spigot pipe

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords