Ductile Iron Pipe ISO2531 / EN545 / EN598 K9 DN100

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 200000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Ductile Iron Pipe Description :

DI pipe fittings are manufactured according to ISO 2531 or BS EN545 or BS4772 FOR POTABLE WATER ,internal is cement lining or wet epoxy coating;External is zinc plus bitumen or wet epoxy coating.

1) Pipes confirm to ISO2531,K9 class,T type joint,6m long,with inside cements lining conform to ISO4179, outside Zinc spraying(130g/m2) and bitumen coating(70μm) conform to ISO8179.

2) Pipe ends: Spigot and socket ends, with 100% SBR rubber gaskets accoding to ISO4633

2.Main Features of the Ductile Iron Pipe:

1. Material: Ductile iron grade 500-7/ 450-10 in accordance with ISO1083

2. Standard: ISO 2531, EN545, EN598, ANSI, AWWA

3. Certificate: ISO9001, ISO14001, SGS, NSF, WRAS

4. Test: In accordance with ISO 2531 / EN 545 / EN598 and 100% water pressure test

5. Length: 6m or cut into 5.6m, 5.7m, 5.8m

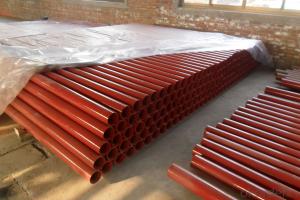

3.Ductile Iron Pipe Images:

4.Ductile Iron Pipe Specification:

Internal lining:ductile iron pipes shall have an internal cement mortar lining in acc with ISO4179.

External coating:ductile iron pipes shall be externally coated with metallic zinc spray plus a further layer of resin painting to ISO8179.

Gasket: 100% SBR/NBR/EPDM rubber gasket in accordance with ISO4633.

Packing:ductile iron pipes from DN100 to DN300 be bundled with steel belts, others are in bulk.

5.FAQ:

1.Q:Why can you guarantee the inner of pipes can’t be corroded?

A: High alumina cement mortar lining and sulphate-resistant cement mortar lining. These two special linings are applicable to inner anti-corrosion for sewage pipes, improving resistance to erosion of the sewage components.

2.Q: Why would you choose ductile iron pipe rather than other pipe materials?

A:The reasons are obvious for that not only ductile iron pipe possesses the inherent strength and flexibility of ductile iron, combined with proven corrosion protection systems, but also the cost savings can be achieved from design to installation and commissioning.

- Q: What is cast iron pipe, specification for cast iron pipe?

- A cast pipe made of cast iron. Cast iron pipes are used for water supply, drainage and gas transmission lines. They include cast iron pipes and pipe fittings.

- Q: Are ductile iron pipes resistant to alkali attacks?

- Ductile cast iron, commonly used in ductile iron pipes, has demonstrated its remarkable resistance to alkali attacks. This is achieved through the inclusion of specific chemical compositions that provide exceptional corrosion resistance. Alkali attacks, which arise from the interaction between alkaline substances and metals or other materials, are effectively countered by the dense and protective oxide film present on both the inner and outer surfaces of ductile iron pipes. This oxide film forms naturally over time and possesses a composition and structure that offer excellent resistance to alkali attacks. Moreover, to further enhance their ability to withstand corrosion and chemical reactions, ductile iron pipes are frequently coated with various protective layers, such as epoxy or zinc. It should be emphasized that although ductile iron pipes exhibit a high resistance to alkali attacks, the severity and concentration of the alkali substances can still impact their overall performance. In extreme instances, where there are exceedingly high concentrations of alkali substances or prolonged exposure to aggressive alkaline environments, some damage may occur to the protective layers of the pipes. Nonetheless, within normal conditions and acceptable parameters, ductile iron pipes are widely regarded as possessing outstanding resistance to alkali attacks.

- Q: Are ductile iron pipes resistant to soil movement?

- Yes, ductile iron pipes are resistant to soil movement. Ductile iron pipes have a high tensile strength, which allows them to withstand external forces such as soil movement. These pipes are designed to be flexible and are able to absorb and distribute stresses caused by ground settlement or other forms of soil movement. Additionally, ductile iron pipes have a strong and durable construction that can resist the compressive forces exerted by the surrounding soil. Overall, ductile iron pipes are a reliable and resilient choice for underground pipelines, providing long-term stability and resistance to soil movement.

- Q: Can ductile iron pipes be repaired if they are damaged?

- Yes, ductile iron pipes can be repaired if they are damaged. The extent of the damage will determine the type of repair that is needed. In cases where the pipe is cracked or has small holes, a repair clamp or a stainless-steel sleeve can be used to seal the damaged area. These methods provide a temporary fix and allow for the flow of water to continue until a more permanent repair can be made. For more severe damage, such as large cracks or broken sections, a full replacement may be necessary. This involves cutting out the damaged section of the pipe and installing a new piece. This process requires specialized equipment and expertise, but it can effectively restore the functionality of the pipe. It is important to note that the repair of ductile iron pipes should be carried out by trained professionals who have experience in working with this type of material. This ensures that the repairs are done correctly and do not compromise the integrity and safety of the pipeline system. Regular inspection and maintenance of ductile iron pipes can help identify any potential issues early on and prevent extensive damage that may require replacement rather than repair.

- Q: Are ductile iron pipes suitable for pressure reducing valve stations?

- Yes, ductile iron pipes are suitable for pressure reducing valve stations. Ductile iron pipes have excellent strength and durability, making them capable of withstanding high pressure conditions. They also have good corrosion resistance, which is essential for long-term reliability in a pressure reducing valve station.

- Q: How are ductile iron pipes protected against abrasion or wear?

- Ductile iron pipes are protected against abrasion or wear through various methods and protective coatings. One of the most common methods is the application of cement mortar lining on the inner surface of the pipe. The cement mortar creates a smooth and hard layer that resists the effects of abrasion and wear caused by the flowing water or other materials passing through the pipe. Additionally, ductile iron pipes can be externally protected by applying a bituminous or epoxy coating. These coatings provide a barrier against external factors such as soil or chemicals that may cause wear or corrosion. The coating acts as a protective layer, preventing direct contact between the iron pipe and the surrounding environment. Moreover, for areas with severe abrasion or wear conditions, special linings or coatings can be applied. Polyethylene encasement or polyurethane lining can be used to provide enhanced protection against abrasion, particularly in areas where the pipe is exposed to high levels of turbulence or abrasive materials. In some cases, ductile iron pipes can also be reinforced with additional materials such as fiberglass or steel wire to increase their resistance to abrasion or wear. These reinforcements provide an extra layer of protection, strengthening the pipe and reducing the likelihood of damage. Overall, ductile iron pipes are designed with a combination of protective measures to ensure their durability and resistance to abrasion or wear. These measures include cement mortar linings, protective coatings, special linings or coatings for severe conditions, and reinforcements. These protective methods help extend the lifespan of the pipes and maintain their functionality even in harsh environments.

- Q: How does ductile iron pipe perform in corrosive soils?

- Ductile iron pipe performs exceptionally well in corrosive soils due to its unique composition and protective lining. The iron in ductile iron pipe is more resistant to corrosion than other materials, such as steel. Additionally, the interior of the pipe is often lined with cement mortar or an epoxy coating, providing an extra layer of protection against corrosive elements. This combination of materials enables ductile iron pipe to withstand the effects of corrosive soils and maintain its structural integrity over an extended period of time.

- Q: Can ductile iron pipes be made of flexible waterproof sleeves?

- The casing can be divided into ordinary casing to be 2-4 cm thick than the pipe to be used and fixed to the wall or plate, and the pipe passes through it. Flexible bushing - between the casing and pipe, with flexible material to seal the sealing effect. Rigid casing - that is, between the casing and pipe with rigid material sealed to achieve sealing effect. Waterproof casing - is the use of the casing of the environment is to prevent liquid leakage or leakage into place (such as the pool, septic tanks, basement, etc.) is on the outer wall of the bushing is not less than 1 times increase waterproof wing, this wall is poured in the casing as a whole, not because of swelling shrinkage factor and crack and leakage.

- Q: Can ductile iron pipes be used for underground chemical processing systems?

- No, ductile iron pipes are not suitable for underground chemical processing systems as they can corrode and react with certain chemicals, compromising the integrity of the system.

- Q: How to analyze and judge the quality of ductile iron pipe

- The quality of water supply pipe ductile is a topic worthy of discussion, how to judge the quality of the ductile iron pipe, ductile now on the market is all kinds of pipe, a name sand type ductile iron pipe, ductile water-cooling tube, K8 grade K9 grade ductile iron pipe, ductile iron pipe, also the brand is divided into ductile ductile pipe pipe, big brands, and some well-known manufacturers of producing ductile pipe,

Send your message to us

Ductile Iron Pipe ISO2531 / EN545 / EN598 K9 DN100

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 200000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords